THERMAL CYCLING ILLUMINATED PHOTODIODES

- Posted by José Luis Corral Castillo

- On February 18, 2022

- 0

160 ILLUMINATED PHOTODIODES

Development of a complex setup capable of simultaneously measuring 20 solar sensors under homogeneous incident light

During the last decades, continuous technology improvement has allowed the development of increasingly smaller and cheaper satellites. Different private companies figured out this fact and started to think about the possibilities of having their satellite constellation. One of the goals of these constellations is to provide high-quality internet services via satellite to any point of the globe. However, achieving this target requires hundreds or even thousands of satellites operating simultaneously. This situation pushes the space market companies to offer innovative solutions to deal with the magnitude of components and devices verifications required for this kind of macro-projects.

Alter Technology has participated in these new space projects in different ways. One of our collaborations was developing a complex setup capable of simultaneously measuring 20 solar sensors under homogeneous incident light during thermal cycles testing. The Device under test (solar sensor) was composed of eight photodiodes, and with them, the sensor was capable of knowing both the direction of the incident light and its intensity.

The complexity of the setup performed was the routing and measurement of such quantity of signals (180) and the generation of a homogeneous illumination for the sensors during the thermal cycling.

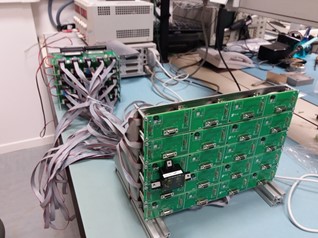

To solve the first obstacle, a PCB (Sensors PCB) was designed, which allowed the fixation of up to 4 sensors and the controlled routing of their photodiodes’ signals. Each PCB includes the possibility of adding up to 4 control photodiodes and four control RTD (PT-100) close to the sensors. Besides, to measure the drop voltage of each photodiode, we use resistance in series with each of them. Another PCB (Resistors PCB) was designed to place all the resistances required. These Resistors PCBs are placed outside the climatic chamber to avoid the thermal influence in the resistance measurement.

Summing up, each Sensors’ PCB is routed to a Resistors’s PCB and finally to a Datalogger. The following pictures illustrate the above description:

Electrical connection check between the Sensors PCB and the Resistors PCB

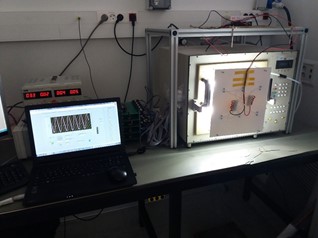

Power source, datalogger and Resistors PCB

Example of a lot of sensors placed inside the climatic chamber and ready to test.

The second challenge was the illumination of the sensors. It was decided to customize one climatic chamber’s door to solve this.

The idea was to open a square hole through the door and substitute it with a window permitting the free pass of the light. The window was made of two transparent polycarbonate surfaces separated for a cavity filled by nitrogen gas. The cavity had two holes allowing the in & out of the nitrogen gas, which helps to hold the temperature in this interface, avoiding the appearance of condensation, which could cause an inhomogeneous light incidence.

Finally, the source light was composed of six lamps fixed to the outside of the door. The following pictures illustrate the door and the overall setup working.

Light source and window

Example of test execution

Lastly, but no less important, the computer. This element controls and monitors all the process from the setup of the equipment until the test records.

All these elements drove us to successfully complete several lots of solar sensors proving their reliability in flying conditions and reducing the cost per lot due to the number of sensors validated at the same time.

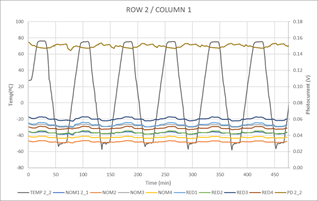

The following picture shows an example of the results of one sensor during one of the tests performed.

Example of results (1 sensor)

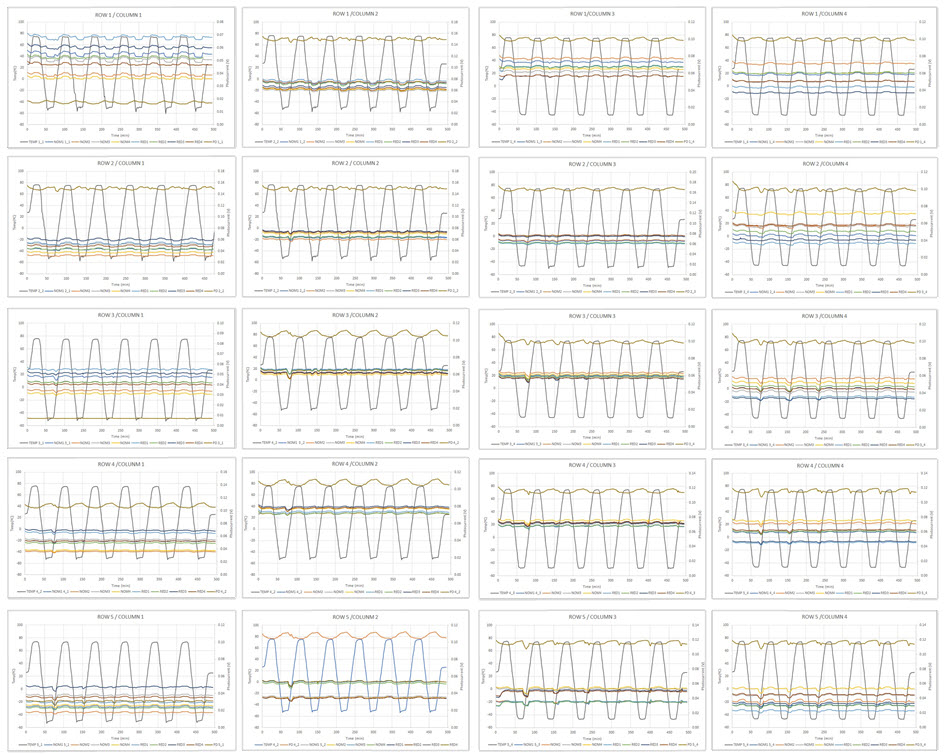

Example of results (20 sensors)

With the system described above, ALTER Technology carried out several thermal cycles campaigns in a successful way. But at the same time, ALTER proved its capability of adaptation in front of the incoming challenges of the new space. Obviously, with the developed system now, we can only measure photodiodes. Still, if the needs change, the system could evolve to measure another kind of component or even to measure in another environment like a vacuum.

Contact us

ALTER TECHNOLOGY LAB EXPERIENCE

- THERMAL CYCLING ILLUMINATED PHOTODIODES - February 18, 2022

0 comments on THERMAL CYCLING ILLUMINATED PHOTODIODES