Resistance To Solvent the Importance marking testing on EEE Parts

- Posted by Jesús Enrique Barbero Muñoz

- On March 28, 2021

- 0

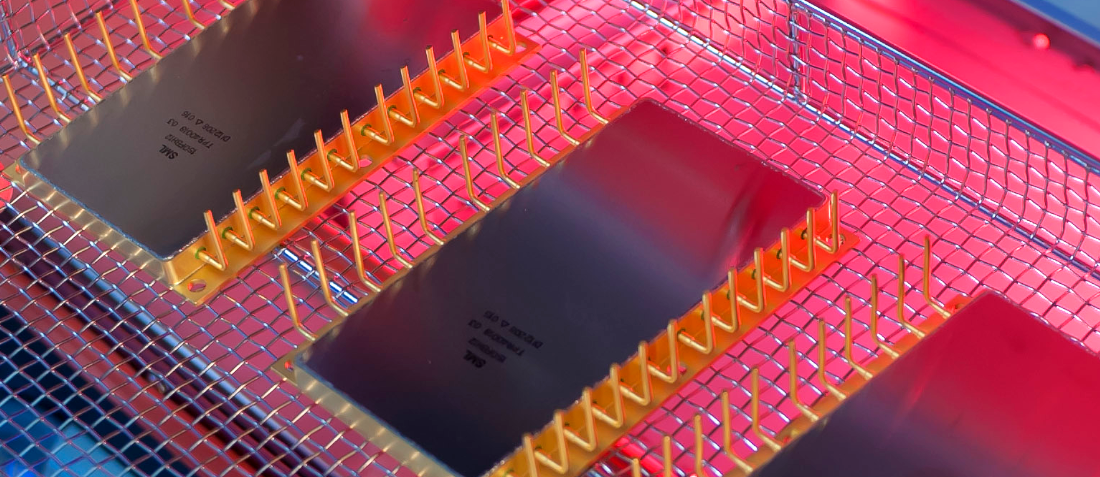

The purpose of this test is to verify that the markings on component parts will not become illegible when subjected to solvents (e.g. during the board cleaning process after parts assembly) or during normal handling, and that the solvents employed for the test will not cause deleterious, mechanical or electrical damage or deterioration of the materials or finishes. The applicable test standards to do the Resistance To Solvent are MIL-STD-750 method 1022, MIL-STD-883 method 2015, or ESCC 24800, among others, depending on the part type.

This test is executed by immersing sample components in the resistance to Solvent specified in the applicable method and then brushing the markings with a small brush. At the conclusion of the test, any evidence of damage to the device, wholly or partially missing markings, and markings which are faded, smeared or blurred to the extent that they cannot be readily identified are interpreted as a failure.

Standars Tests PDF Files

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Lead Integrity Test, How to be perform - October 15, 2021

- Resistance To Solvent the Importance marking testing on EEE Parts - March 28, 2021

- Bond Pull Test - October 14, 2020

0 comments on Resistance To Solvent the Importance marking testing on EEE Parts