Outgassing and Mating Test

- Posted by Pedro CARABIAS LÓPEZ

- On May 6, 2020

- 0

Outgassing and Mating Test on High Voltage Connectors for Solar Orbiter ESA/NASA Mission

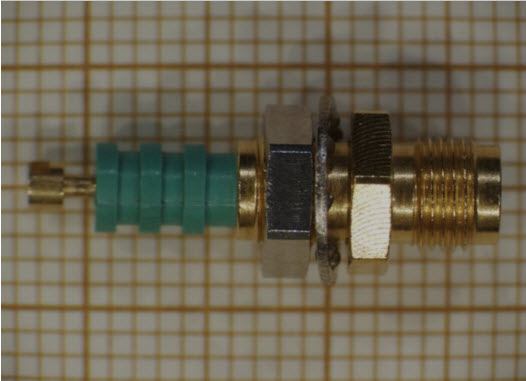

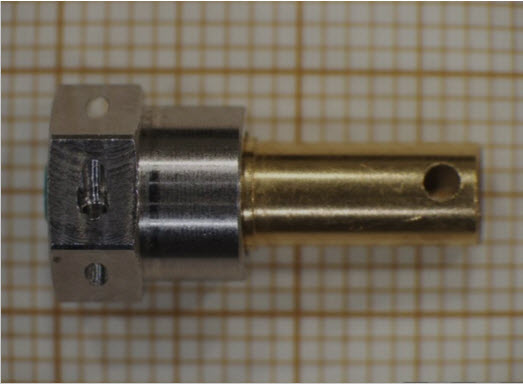

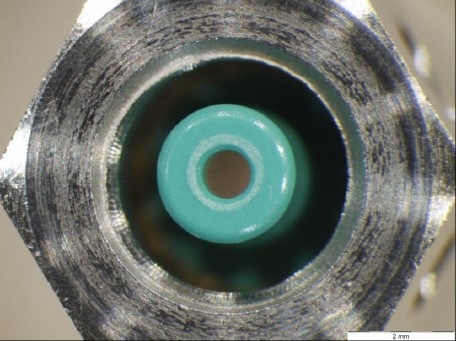

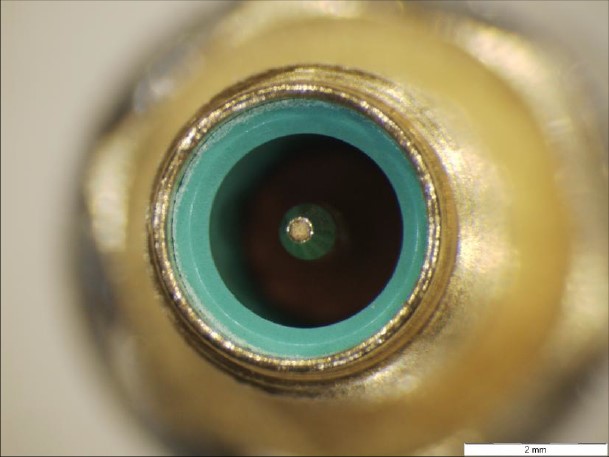

Mating test was requested in order to confirm that no gold flakes from gold thread (receptacle connector) would spread out within space vacuum environment after satellite launch due to the greater hardness of stainless-steel nut (plug connector).

The applied testing sequence was including Cleaning Process, preliminary External Visual Inspection, Mating/Unmating process of different cycles, and finally a new External Visual Inspection after each process cycle:

-

- Cleaning sequence was based on irrigating all connectors with Isopropyl Alcohol and blown dry in accordance with manufacturer recommendation.

- During External Visual Inspection shells, pins, threads and green sealing interfaces were inspected. The goal was to double-check that all the external surfaces were free of foreign particles and contamination, as well as no evidences of corrosion, peeling of finish or plating nor any holes or cracks, neither flakes of the plating.

- For Mating/unmating process, plug connectors and receptacle connectors were threaded after applying an Oil layer with an small portion of antistatic foam. Please contact Alter Technology for further details about the specific Oil applied.

Once connectors surfaces were wet completely with this oil, now mating process of both connectors was performed by using a torque sensor to measure applied force, the exact force was applied according manufacturer instructions.

After reaching the accurate requested torque force, mating process was completed.

Unmating process was just based on applying the necessary force to unscrew both connectors according manufacturing instructions. These steps were repeated in each new cycle of mating / unmating.

Outgassing test was also performed by Alter Technolgy in accordance with ECSS-Q-ST-70-02C requirements on plastic materials included into connectors which were susceptible to outgassing issues.

An assessment was performed on tests outcomes with regards to ECSS-Q-ST-70-02C parameter limits:

- CVCM<0.10%

- RML<1.00%

When reabsorbed water is not deemed, then TML = RML, since by definition: RML = TML – WVR.

RML stands for recovered mass loss, it is the total mass loss of the specimen itself without the absorbed water.

The RML is introduced because water is not always seen as a critical contaminant in spacecraft materials.

Where WVR is water vapor regained mass of the water vapour regained by the specimen after the optional reconditioning step, CVCM is the collected volatile condensable material, and TML is the total mass loss of material outgassed from a specimen that is maintained at a specific constant temperature and operating pressure for a specified time.

This equivalence terminology is useful when applying both standards NASA ASTM E595 and ECSS-Q-ST-70-02C.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Outgassing and Mating Test - May 6, 2020

- Quality/reliability issues and detection on High Reliability Optocouplers - April 29, 2020

- Voids on sealing area. - February 10, 2020

0 comments on Outgassing and Mating Test