SAM: Test flow and procedures

- Posted by Francisco Javier Aparicio Rebollo

- On September 17, 2020

- 0

SAM: Test Flow And Procedures For The Assessment Of Delamination Flaws And Historical Results Review

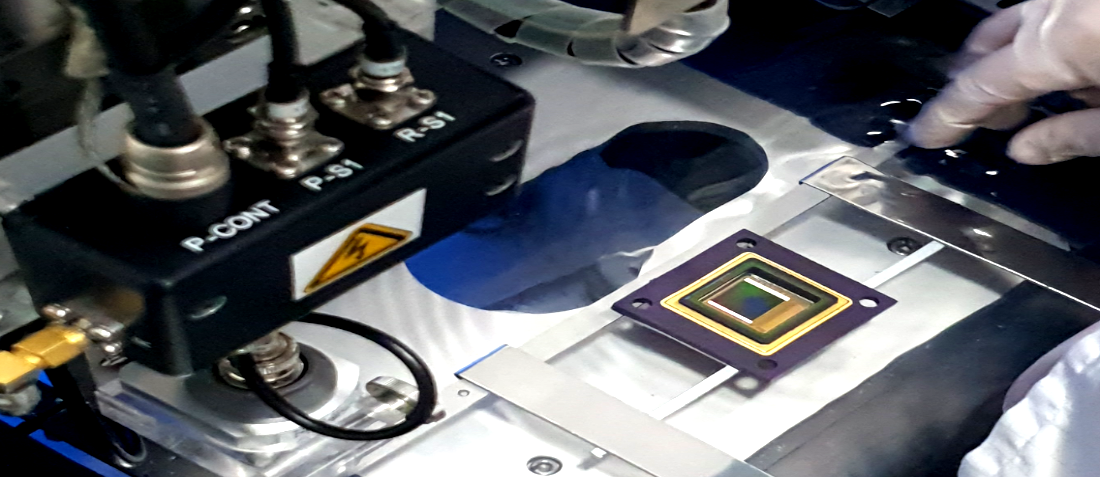

Nowadays Scanning Acoustic Microscopy (SAM) is extensively used in the non-destructive inspection of microelectronic devices and is present in different space verification programs; particularly for plastic-encapsulated electronic components. This is so due to the ability to image the internal morphology, location, size and distribution of hidden features including different types of flaws. Therefore, it has high prospects to be one of the key inspection tools for reliability assessment and screening of novel 3D assemblies including buried technologies, as well as new lead-free soldering solutions.

Industrial and space standards such as IPC/JEDEC J-STD-020E, ESCC 25200 and PEM-INST-001 state rejection criteria for SAM inspection, or the bases to perform additional verification tests. The strict rejection of any delamination flaw detected by SAM would lead to unnecessary high rejection ratios due the high sensitivity of the technique to horizontal features.

These specifications put the focus on the potential effect of the delamination over the system reliability, which is a sometimes-subjective concept subjected to interpretation. In addition, ESCC specification also indicates that SAM inspection must be combined with stress tests, but it does not specify the type and intensity of the treatment. Thus, additional studies are required to state more clear procedures and rejection criteria in order to address the already present COTS revolution.

In this context, the present communion, divided into 6 sections, aims to shed light on this subject and to share with the audience the detailed verification procedures and rejection criteria proposed by Alter Technology. In agreement with ESCC, IPC/JEDEC and PEM-INST-001 specifications this approach combines accurate SAM inspections and well-defined thermomechanical stress tests (including thermal cycling).

Additionally, the proposed methodology also makes use of metallographic inspection by high magnification electron microscopy and functional and mechanical tests to verify the actual conditions and reliability of those specimens displaying internal flaws. The approach is supported by the large experience on EEE inspection involving 6 different acoustic microscopes for more than 30 years.

Read More about SAM Test Flow and Procedures

Contact us

Co-authors: David Ramírez-Cruzado Monge; Jose Cándido Vázquez, Dimas Morilla Mairen, Manuel Domínguez Álvarez, Antonio Rodríguez Arenas.

- Material Analysis Techniques for Electronic Components - May 6, 2022

- SAM: Survey to manufacturers and users - February 17, 2022

- What is a C-SAM Inspection? - January 29, 2022

0 comments on SAM: Test flow and procedures