Experiments done in Tin Whiskers Growth

- Posted by Dimas Morilla

- On July 30, 2020

- 0

Experimental Methods

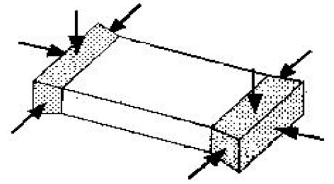

The surface mount device beads under study have two rectangular contacts at opposite sides. With bends of 90 degrees that have an approximately planar surface of 3.048 mm2 each. In order to comply with the standard JESD22-A121, 12 leads on at least 6 components must be examined, with an accumulated lead surface bigger than 75 mm2. Look for in doEEEt the most appropriate component quality level for your application.

Therefore, 13 SMD beads were used for each one of the three tests (hence, 39 beads of each part type) so that the surface of 13 x 2 contacts x 3.048 = 79 mm2 is above the minimum amount required.

| wdt_ID | Sample Type | Tin Finished Area | Minimim Total Inspection Area for Screening Inspection | Minimum Numbers of Samples | Minimum Inspection Surface Area per Sample for Screening Inspection | Minimum Total Number of Inspection Areas for Screening Inspection |

|---|---|---|---|---|---|---|

| 1 | Components | ≥ 0.85 mm2 | 6 | 75 mm2 | Top and 2-3 sides of termination | 75 mm2 ÷ (Plated area on top and 2-3 sides of termination) |

| 4 | Components | < 0.85 mm2 | 6 | 75 mm2 | Top and 2-3 sides of termination | 96 |

| Sample Type | Tin Finished Area | Minimim Total Inspection Area for Screening Inspection | Minimum Numbers of Samples | Minimum Inspection Surface Area per Sample for Screening Inspection | Minimum Total Number of Inspection Areas for Screening Inspection |

Table 1: Details on the number of test samples and terminations required for comparison of screening inspection data.

Figure 1. A schematic drawing depicting a leadless component and the top and 3 sides of the terminations that should be inspected.

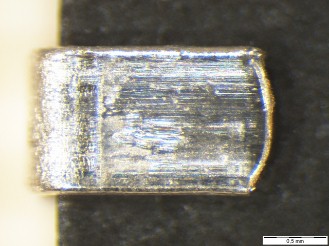

Figure 2. View onto a contact.

The beads were inspected before the tests using a binocular microscope at 72.5x magnification in order to determine if whiskers were present at the beginning of this study.

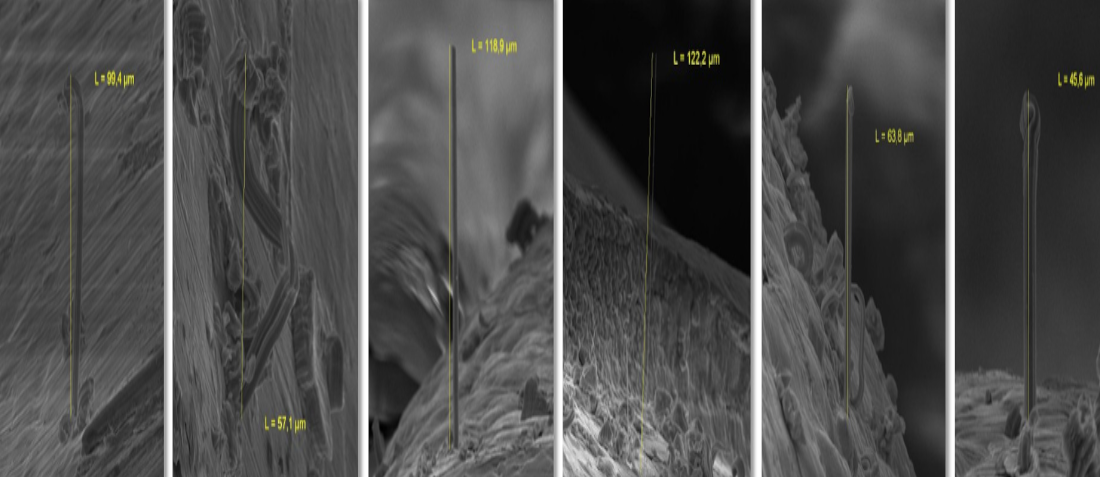

Detailed inspections were performed on the leads of all the samples from the three lots after each test condition using a scanning electron microscope.

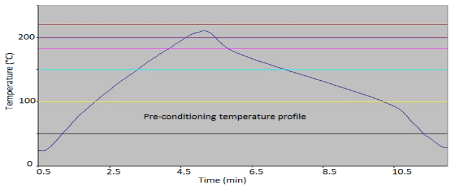

Moreover, and as recommended by the JEDEC standard, a preconditioning heating treatment was applied to all parts prior to the start of the test programme.

Figure 3. Temperature profile applied for preconditioning the three lots of 39 SMD beads.

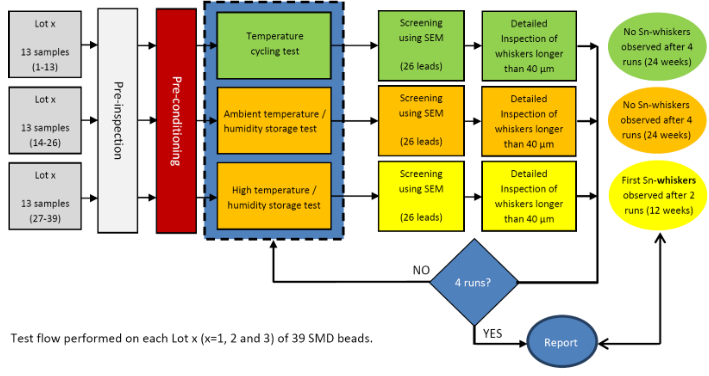

During the screening performed at Alter Technology, each lot of surface mount device beads (39 per part type) was divided into three groups of 13 beads:

The first group of 13 parts was submitted to Temperature Cycling (1000 cycles per run).

The second group of 13 parts was submitted to Ambient Temperature/Humidity Storage(1000 hours per run).

The last group of 13 parts was submitted to High Temperature/Humidity Storage(1000 hours per run).

Each test was repeated four times (or runs) in order to exceed the minimum duration recommended by JEDEC.

Figure 4. Temperature shock test cabinet and humidity chamber.

A summary of the conditions used for testing and a schematic of the test flow is shown in Table 2 and Figure 5 respectively.

| wdt_ID | Tests (for each lot) | Condition | Inspection Intervals | Numbers of runs | Total Duration | Anomalies |

|---|---|---|---|---|---|---|

| 1 | Pre-conditioning | See profile in Figure 2 | -- | -- | -- | -- |

| 4 | Temperature Cycling | Min Temperature: -55 or -40 (+0/-10) °C Max Temperature: +85 (+10/-0) °C, Air to air; 10 minutes soak; ~3 cycles/hour | 1000 cycles | 4 | 4000 cycles | None |

| 7 | Ambient Temperature/ Humidity Storage | 30 ±2 °C and 60 ±3% RH | 1000 hours | 4 | 4000 hours | None |

| 10 | High Temperature/ Humidity Storage | 55 ±3 °C and 85 ±3% RH | 1000 hours | 4 | 4000 hours | Whiskers were detected after 2 runs |

| Tests (for each lot) | Condition | Inspection Intervals | Numbers of runs | Total Duration | Anomalies |

Table 2: Tests and conditions applied for accelerating the growth of Stanium whiskers.

Figure 5. Schematic of acceptance test flow carried in Alter Technology on each lot x (x = 1, 2 and 3) of 39 SMD beads. The tests are applicable for two leaded Class 2 components using Copper (Cu) lead frame with Ni underlay mitigation technology and Stanium (Sn) 100% finish.

- Würth Elektronik Presents Radio Interference Suppression Ceramic Common Mode Filter - December 24, 2021

- Results after the Tin Whisker Growth Investigations - December 4, 2020

- Why do a Residual Gas Analysis? - August 28, 2020

0 comments on Experiments done in Tin Whiskers Growth