Evaluation of Optical switches without moving parts

- Posted by David Poudereux Sánchez

- On January 27, 2022

- 0

ABSTRACT

We have carried out a test campaign of thermal vacuum cycles, mechanical tests (vibration and shocks) and radiation tests (gamma radiation) to evaluate the performance for space applications of commercial off-the-shelf fiber coupled optical switches with no-moving parts, based on different technologies.

The technical requirements of several space applications of optical switches were defined. After the technology selection, a tradeoff was performed to select the final optical switches to be tested, which are based on three technologies: Magneto-Optic MO, Bulk Electro-Optic B-EO, and Waveguide Electro-Optic W- EO and fabricated by four different manufacturers. Other potential technologies (acousto-optic, liquid crystal, thermo-optic, micro/nano photonic waveguides) were not selected due to the lack of commercial products.

The main performance parameters were the insertion loss, crosstalk, and switching speed. After the final electro-optical characterization, a destructive physical analysis was made to some optical switches. The results of the tests indicated that B-EO and MO technologies are excellent candidates for the analyzed space applications.

They respond very well under typical space conditions as radiation, vibration, shocks and thermal vacuum; B-EO technology presents lower switching time but its crosstalk is worse. WG-EO technology is very fast, but a mechanical failure in one device was observed, the insertion losses are very high and the crosstalk is very low.

1. SELECTION OF DEVICES

The nominal characteristics of the components offered by more than ten manufacturers were analyzed. The manufacturers were contacted and additional information (reliability, options for custom components, previous use in space applications, etc.) was requested. After a trade-off process at component level, eight different commercial models of optical switches fabricated by four manufactures using the three technologies (MO, B-EO and WG-EO) were selected for the testing.

2. TEST PLAN

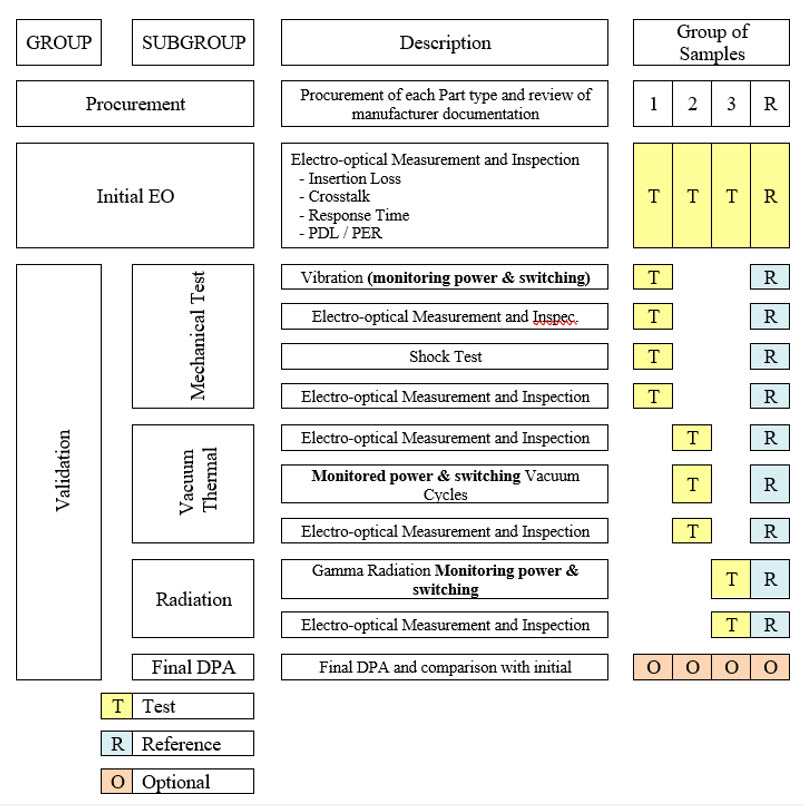

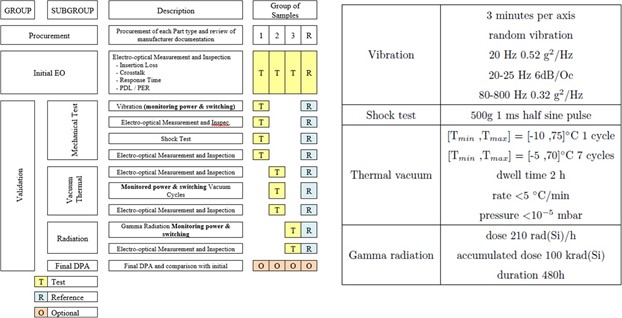

After procuring the selected components, a test plan space applications was defined.The test plan, for those part types with several samples, is shown schematically in Fig. 1

3. ELECTRO-OPTICAL CHARACTERIZATION

All the samples were characterized at the beginning of the testing and after each step of the test plan. The characterization included the following measurements:

- Insertion Loss (IL): it was determined using as reference the power measured using a patchcord instead of the switch. Due to the repeatability of the FC/APC fiber connectors the estimated uncertainity of the IL was ±0.3 dB

- Crosstalk (CT): defined as the ratio, in dB, between the power at the input and the power at the non-selected output. It was measured simultaneously with the IL considering the switch with one input and two outputs and measuring the power in the two outputs.

- Response Time: it was measured by using a control signal (nominally squared) from a signal generator to switch the output power and monitoring the power at both outputs with fast photodiodes and an oscilloscope. The response time was defined as the delay difference between the control signal and the output power during the switching. Return Loss (RL): measured with the help of a 1×2 splitter/combiner and of a fiber optic light trap to determine the reference level.

- Polarization Dependent Losses (PDL): measured by placing a polarization controller at the input of the optical switch and rotating the polarization in all states while the optical power at the output was monitored.

- Polarization Extinction Ratio (PER): measured for those samples with PMF. It was measured with the help of PER tester and a PMF coupled laser diode.

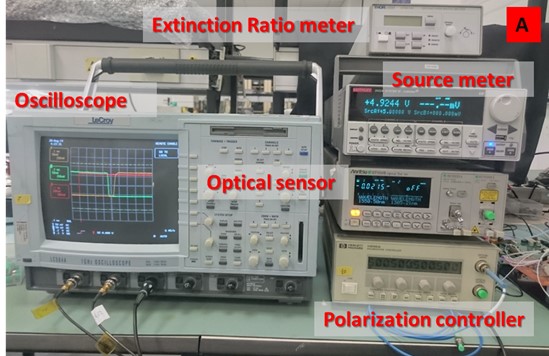

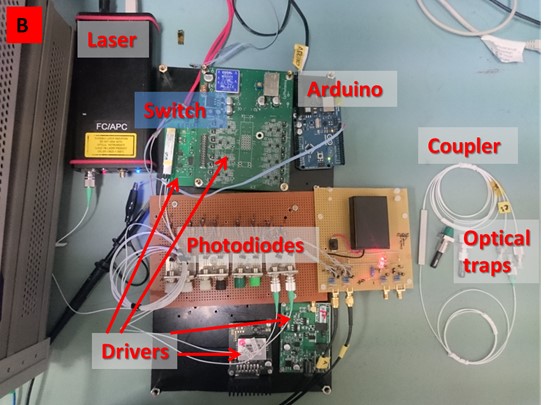

All the measurements were performed at room temperature using a 1550 nm low power laser. The results of the initial electro-optical characterization were used as reference for each sample. The main equipment showed in the following picture A are an oscilloscope (LeCroy LC 564A), an optical meter (Anritsu MT9810B – MU931411A optical sensor), a polarization controller (Hewlett Packard 11896A), a two channel source meter (Keithley 2602A) and an extinction ratio meter (Thorlabs ERM100) (see Figure 2).

4. TEST RESULTS & CONCLUSIONS

The most relevant result of this work is that all tested samples passed satisfactory the test without relevant changes in the measured parameters, with the exception of one of the WG-EO switches which had a catastrophic failure, as it will be commented later. The pass/non-pass criteria were defined comparing the results of the electro-optical characterization after each test with the corresponding results for each parameter prior to the tests, taking into account the measurement uncertainty.

The conclusions of our study are summarized as follows:

- Optical switches based on B-EO and MO technologies are excellent candidates for the analyzed space applications. They respond very well under typical space conditions as radiation, vibration, shocks and thermal vacuum.

- B-EO technology behaves slightly better than MO technology and it is the choice for those applications requiring high switching speed. However, its crosstalk is worse.

- MO technology exhibits very good properties, except for the switching time. Moreover, there are many manufacturers and commercial products fabricated with this technology.

- WG-EO technology has very fast response. The observed mechanical problems could be solved by a better gluing procedure. However, these switches are very complex to handle and control, their insertion losses are very high and the crosstalk very low.

- No difference has been found between the behavior of polarization maintaining fibers and single mode fibers.

- The low power MO devices and the high power devices from the same manufacturer behave similarly when tested at low power.

In summary, the results of this work pave the way for the future use of optical switches without moving parts in space applications. Further work is still necessary to assess the practical use: each future application should select the appropriate switch in terms of wavelength, type of fiber, maximum power, switching speed, and the technology should be tested to demonstrate the achievement of the required lifetime or number switching cycles.

Alter Technology LAB services

THERMAL VACUUM: TVAC Testing is necessary to be carried out because the environmental conditions in the space are extreme, the combination of low pressure and the extreme temperatures can cause the failure of a component. That is why we test the components in similar conditions.

MECHANICAL TEST: Depending on the intended application electrical components are exposed to either transitory or permanent dynamic mechanical stress which can impair the performance, so to ensure the proper system operation under such conditions, the components must be submitted to thorough vibration test before their implementation for space.

RADIATION TEST: Radiation testing effect is one of the main factors affecting the reliability of equipment and systems operating in space. It degrades components and generates device perturbations that could lead to its malfunction or destruction.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

ALTER TECHNOLOGY LAB EXPERIENCE

- Photonic Integrated Circuits Radiation - January 31, 2022

- Evaluation of Optical switches without moving parts - January 27, 2022

- Photonic Integrated Circuits radiation for harsh environments - September 23, 2021

0 comments on Evaluation of Optical switches without moving parts