Radiation Effects and Test Flow for TID Testing

- Posted by José Joaquín González

- On October 29, 2020

- 0

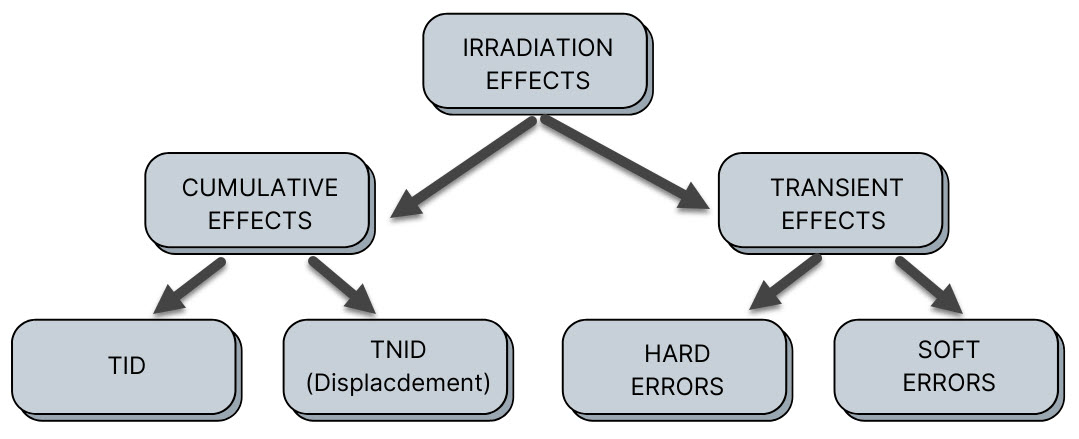

Cumulative effects are gradual effects taking place during the whole lifetime of the electronics exposed in a radiation environment. A device sensitive to TID or TNID will exhibit failure in a radiation environment when the accumulated dose (TID) or particle fluence (TNID) has reached its tolerance limits. So, in a certain way, it is possible to foresee and predict how the devices are going to behave.

TID effects imply that one incident irradiation causes the ionizing of matter and it appears charge in places where it should not. TNID effects are motivated by the displacement of the atoms of the crystalline lattice from their balance sites.

On the contrary, Transient Effects (commonly named Single Event Effects) are due to the energy deposited by one single particle in the electronic device. So, it is a probabilistic effect, and a device sensitive to SEE can exhibit failure at any moment since the beginning of its operation in a radiation environment.

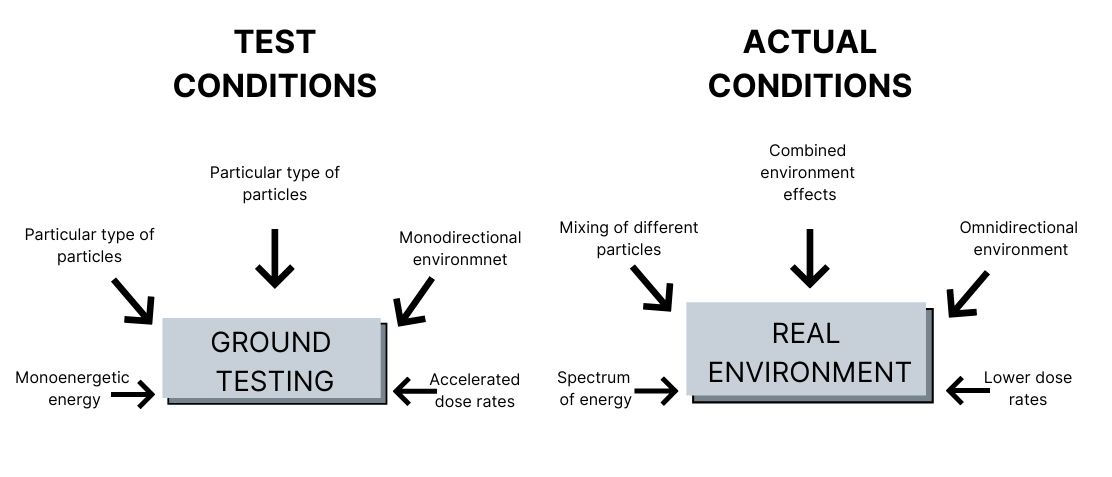

But what radiation we refer to? In most of the cases, it is space radiation. But, in the real environment, the dose rate usually is shallow and our space missions last years. We cannot wait for years and, therefore, we need to accelerate by an important factor the dose deposition.

We use the irradiation laboratory to simulate this time in a short period of testing.

Parameters for Taking into account in TID Test.

Radiation source:

There are several possibilities to choose, although the methods we are going to introduce the use of gamma-ray with 60Co sources or electron sources using an accelerator. Key concepts in this point are intensity and field uniformity.

Dosimetry:

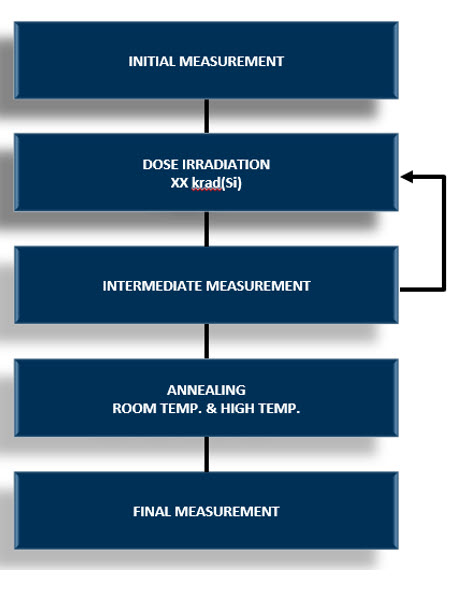

The dosimetry process consists of finding the dose rate the parts will suffer during the irradiation test. We can obtain the dose rate through the direct measurement or by decay calculation.

Electrical testing:

There are two possibilities: In situ or remote testing.

- In-situ testing: The samples will be in the irradiation chamber during the whole irradiation test while the electrical measurement is performed.

- Remote testing: The samples are measured once they are removed from the irradiation chamber.

Dose:

The dose is the amount of absorbed energy within the considered material. In this case, Silicon.

Bias condition:

Bias condition means the power supply condition, and the biasing circuit the samples are going to be inserted.

Environmental conditions:

Since the dosimetry is strongly depended on the temperature, pressure and humidity, the control of these conditions turns out a critical point during the irradiation test. If these parameters change during the test, the dose rate the components receive will be different from the previously calculated in the dosimetry process or by decay calculation.

And, of course, the temperature is vital during the electrical test.

Test Methods

Due to the way to perform the irradiation test may affect the results, standards have been written, so that describe the test method to apply and also the characteristics of the irradiation facilities to use.

Focusing on TID test, there are four main test methods for total ionizing dose tests:

- ESCC 22900-5: “Total Dose Steady-State Irradiation Test Method” from ESCC (“European Space Component Coordination”).

- MIL-STD-750 TM1019.5: “Steady-State Total Dose Irradiation Procedure” from MIL-STD (“US Military Standards”).

- MIL-STD-883 TM1019.9: “Ionizing Radiation (Total Dose) Test Procedure” from MIL-STD (“US Military Standards”).

- ASTM F1892 -12 (2018): “Standard Guide for Ionizing Radiation (Total Dose) Affects Testing of Semiconductor Devices”.

All of them covering both evaluation and qualification steps, although only the European standard split into those two sections the text of the standard. The European standard covers the irradiation testing (TID) of integrated and discrete semiconductors suitable for space applications, whereas MIL-STD uses two methods for covering both of semiconductors. MIL-STD-750 is intended for testing discrete semiconductor devices, and MIL-STD-883 is intended for testing integrated circuits.

So, the answer to the question “What method should we choose?” is “it depends”. Not only, for the kind of devices the methods are intended, but for other features which will be summarized following.

Anyway, it is recommended to edit a test plan were all concepts (electrical and radiologic) are defined, and both customer and test house agree.

- Standards of Irradiation TID Tests for Space Applications - October 30, 2020

- Radiation Effects and Test Flow for TID Testing - October 29, 2020

0 comments on Radiation Effects and Test Flow for TID Testing