Inspection of thick EEE plastic encapsulated parts – CSAM Services

- Posted by Francisco Javier Aparicio Rebollo

- On June 27, 2019

- 0

Multi-depth Confocal Acoustic of Inspection of thick EEE plastic encapsulated parts

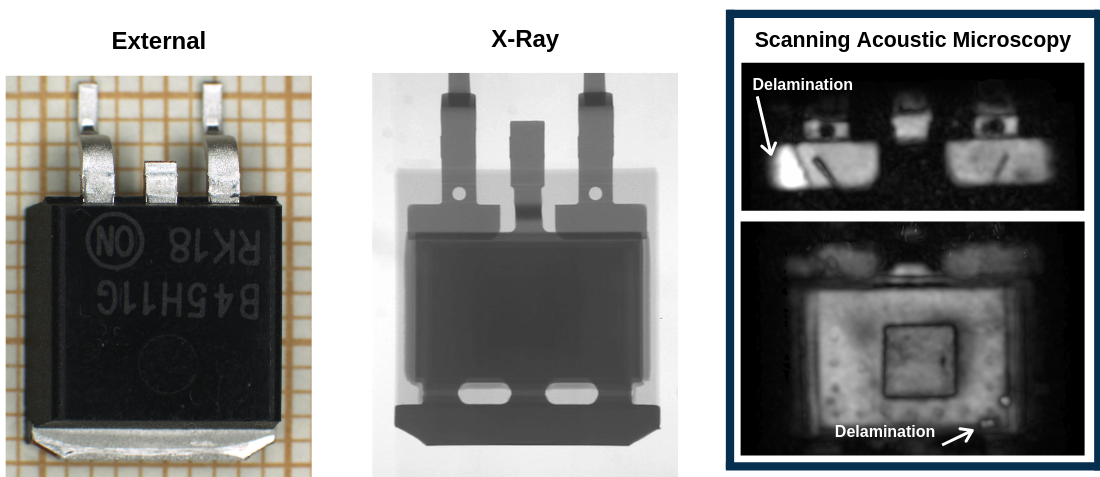

Sample & Method

High-resolution inspection of plastic encapsulated systems with complex internal architectures requires of confocal imaging techniques to block out-of-focus features that otherwise impair the resolution and the image quality.

In the particular case of thick plastic packages D2PAK (TO-263), a thorough and comprehensive inspection is achieved if we perform multi-depth confocal analyses at different focal planes of interest. Such analyses are only possible by making use low-frequency transducers providing large inspection depth or broadband probes in combination with suitable filters to improve the resolution in the case of shallow features.

| wdt_ID | Component type | Package | Anomaly 1 | Anomaly 2 | Anomaly 3 |

|---|---|---|---|---|---|

| 1 | Silicon power transistor | D2PAK (TO-263) | Leadframe delamination | Voids at the die attack | Paddle delamination |

| 4 |

Remarks

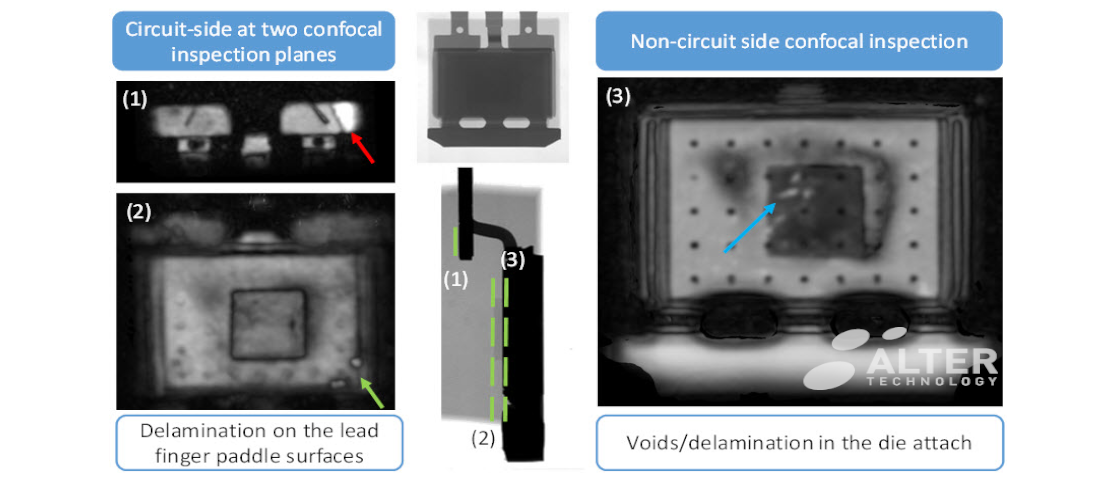

Multi-depth confocal inspection reveals minor and major defects at different inspection planes. These included smaller delamination at the molding paddle interface (green arrow in the circuit side inspection), and voids within the die attach (blue arrow in the non-circuit side inspection). The most remarkable deviation is the delamination observed at the lead frame in the proximity of the wire bonding area (red arrow in the circuit side inspection). All these anomalies are acceptable in accordance with the criteria stated in the specifications J-STD-020E.

Contact us

- Material Analysis Techniques for Electronic Components - May 6, 2022

- SAM: Survey to manufacturers and users - February 17, 2022

- What is a C-SAM Inspection? - January 29, 2022

0 comments on Inspection of thick EEE plastic encapsulated parts – CSAM Services