Doing a Confocal Acoustic Inspection on Optoelectronic Components

- Posted by Francisco Javier Aparicio Rebollo

- On July 3, 2019

- 0

Sample & Method

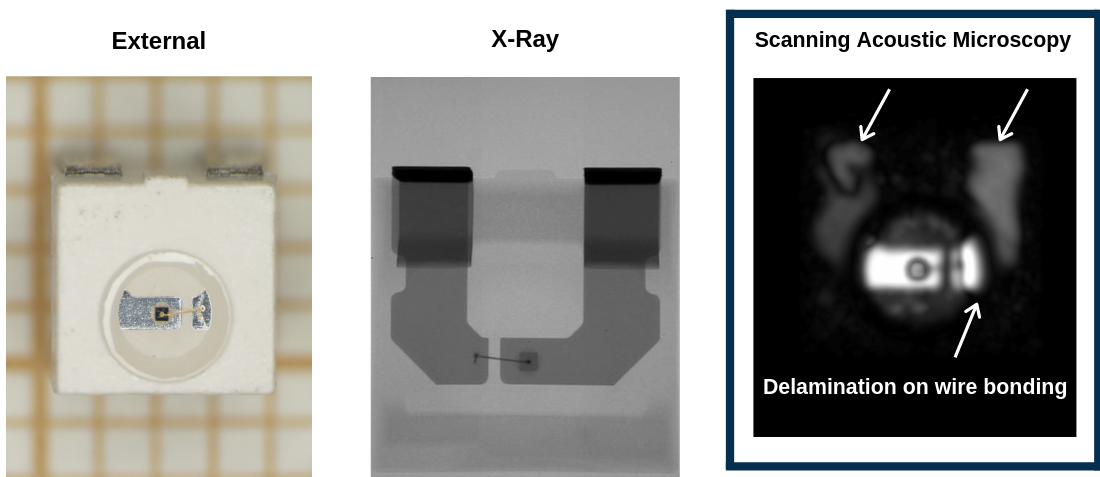

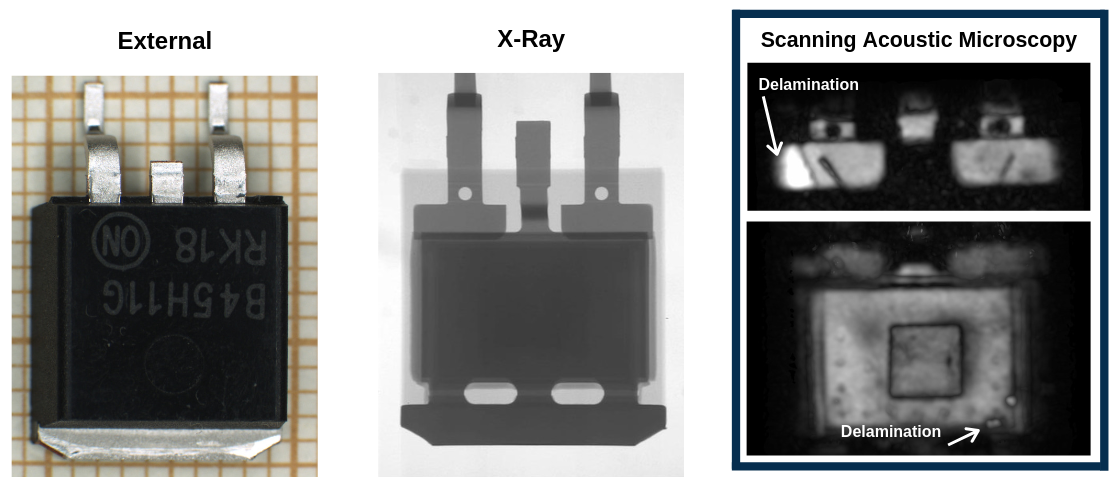

An Infra-red led emitter is inspected by scanning acoustic microscopy. Probe frequency is adapted to the characteristics of the system. In this case, considering the large thickness of the package a 50 MHz transducer is used. Our phase inversion algorithm identifies and highlights the delaminated areas. In addition, A-scan inspection is used to confirm these findings.

Remarks

Thorough scanning acoustic inspection discloses defects at different locations. First of all, minor acceptable delamination is observed at the rear side of the paddle. However, the detected delamination on the lead-frame wire bonding area compromises the system performance. On the other hand, one lead is delaminated over its entire length. This delamination extends from the external surface of the package up to the active area and represents a severe risk of water ingress.

Assessment as per different test methods

In Alter Technology Scanning Acoustic Microscopy inspection is conducted in accordance with different inspection methods. Next table summarizes the inspection result for these different criteria.

Contact us

- Material Analysis Techniques for Electronic Components - May 6, 2022

- SAM: Survey to manufacturers and users - February 17, 2022

- What is a C-SAM Inspection? - January 29, 2022

0 comments on Doing a Confocal Acoustic Inspection on Optoelectronic Components