Ripple current and its effects on the performance of capacitors

- Posted by doEEEt Media Group

- On October 7, 2020

- 0

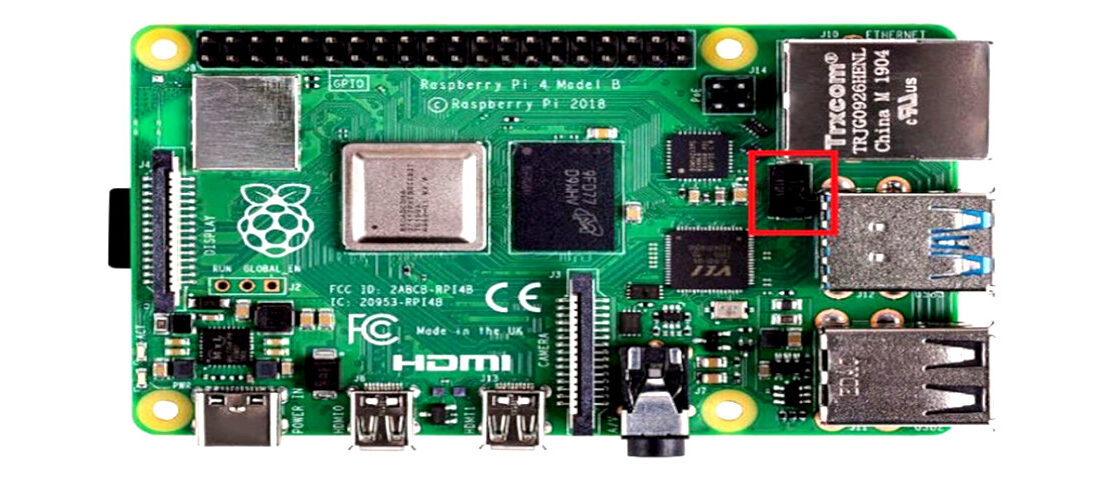

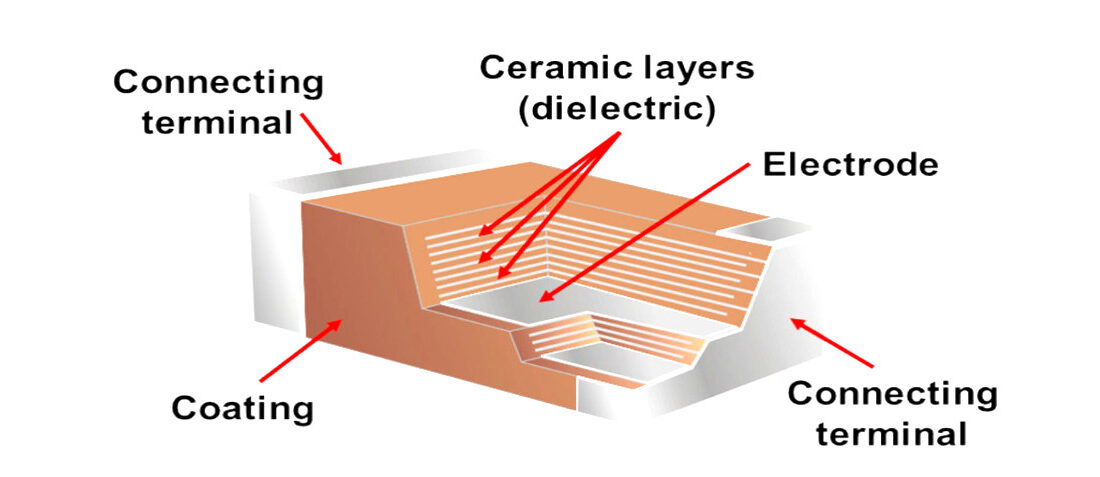

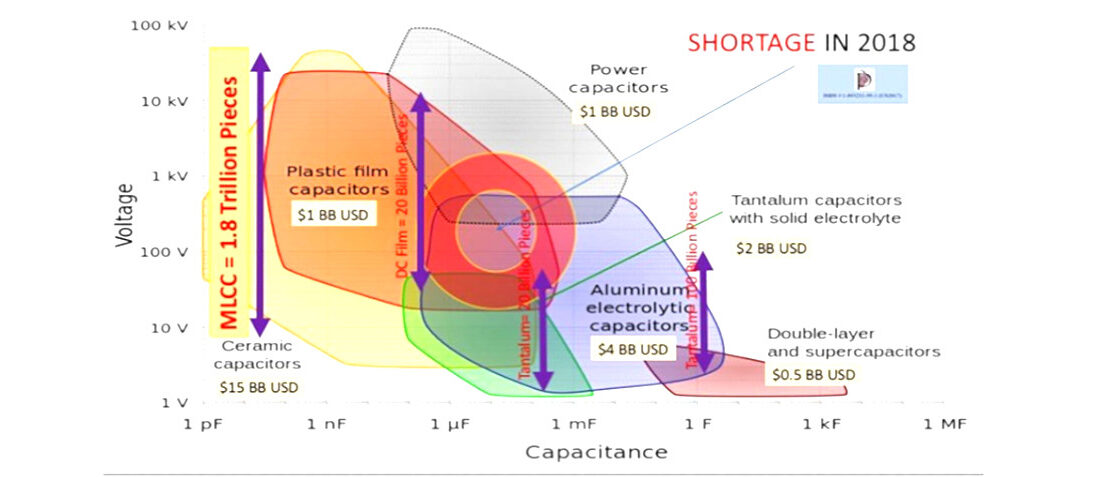

Capacitors are critical elements in most analog and digital electronic circuits. They are used for a broad array of applications including decoupling, filtering, bypassing, coupling, and so on. Different applications have different performance requirements and demand capacitors with specific characteristics. The power dissipated by a capacitor is a function of ripple current and equivalent series resistance. As such, the ripple current capability is one of the key parameters to consider when selecting a capacitor for a specific application. Other critical parameters include capacitance, voltage rating, equivalent series resistance, and equivalent series inductance.