Main changes in ECSS-Q-ST-60-14C, EEE Components Relifing procedure

- Posted by Daniel Cruz Fuentes

- On October 1, 2019

- 0

Space industry is especially careful with the quality and reliability aspects of the EEE parts used in any application. In this sense, and depending on the project class, electronic components have to be submitted to different set of tests like burn-in, thermal cycling, seal test, humidity test, etc…

But, once all test and controls have been successfully passed, can be considered the parts as “Space Qualified” forever? The answer is ‘NO’. As a general rule, a very old device should not be used in the application even though the storage had been done in the proper controlled conditions (temperature and humidity).

An important parameter to be taken into account before parts assembly is the Date Code, which gives information about device’s manufacturing date. But, when can be considered a device “too much old” to be used in the application? The ECSS-Q-ST-60-14C procedure was written in order to have a standard which regulates the use of devices that have been stored. This standard specifies the “relifing” requirements to be considered on EEE parts that are intended to be used for space applications.

What is a “relifing”? The relifing process is a lot quality control activity for parts that have been stored during a time and will be used in a project, but taking into account that, inspections and tests defined do not constitute an up-screening or up-grading of components to a higher level of quality than procured to. And finally, the Relifing process will certify as “fit” a device’s lot.

The ECSS-Q-ST-60-14C has been used as a reference for this relifing activity, since its creation, in November 2008. And, a new revision of ECSS-Q-ST-60-14C has been released last August 1st, 2019 with the following main changes:

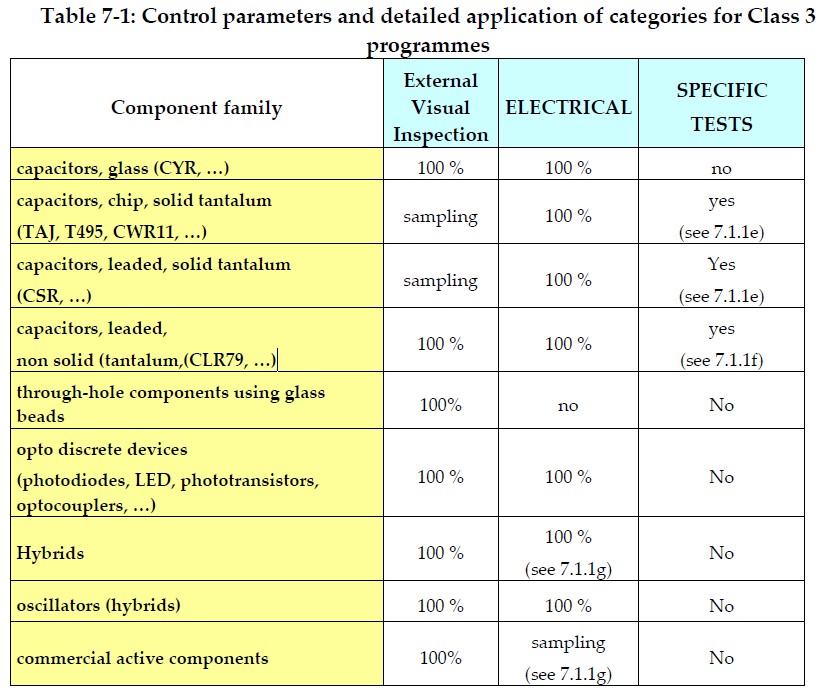

1.Creation of two relifing flows: one covering Class 1 & 2 components and the other covering Class 3 components.

Class 3 is limited to only a few of families:

In this Class 3 requirements, note the absence of Seal Test.

2.Introduction of the applicability of the relifing requirements to commercial components.

-

- The sentence “This standard does not cover the relifing of commercial parts” has been removed in this new revision.

- ECSS-Q-ST-60-13 has been included as reference.

- A new bullet has been included in paragraph 6.1.1 (bullet “q”) and in paragraph 7.1.1 (bullet “h”) exclusively dedicated to commercial parts

3.Change of timing requirements for relifing. Now, it’s increased the maximum elapsed time between date code and time of mounting from 10 to 15 years.

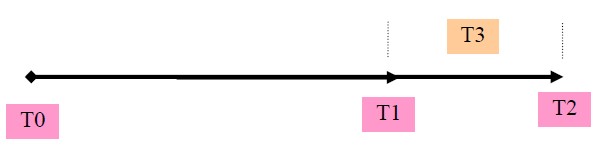

In the first issue, the time line was:

Where:

- T0: Original date code

- T1 (7 years): Maximum allowed storage period from T0 with no relifing control.

- T2 (10 years): Maximum duration between the original date code of part and its mounting.

- T3 (3 years): Maximum allowed storage period after a relifing control.

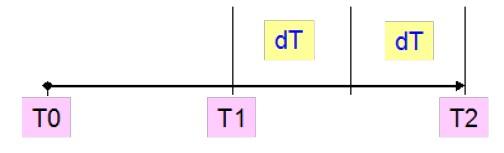

Now, in Revision 1, the new relifing time line is:

Where:

- T0: Original date code

- T1 (7 years): Maximum allowed storage period from T0 with no relifing control.

- T2 (15 years): Maximum duration between the original date code of part and its mounting.

- dT (4 years): Maximum allowed storage period after a relifing control which can be repeated once.

4.Change in Sampling. For Electrical Measurements and External Visual Inspection, for some families, the test is performed by sampling. In the original ECSS-Q-ST-60-14C, the sampling was given in accordance with following rule, calculated with respect to the number of relifed parts:

-

- Lot <80pcs: 100%, with 0 defect allowed

- Lot 81 to 280pcs: sampling is 80 parts, with 0 defect allowed

- Lot >280pcs: sampling is 80 parts, with 1 defect allowed

Now, in Revision 1, the sampling has been normalized to AQL 0,65% level II according to ANSI ASQ Z1.4-2003 Revision 2008.

Apart of these main changes, there are some minor editorial changes.

- Main changes in ECSS-Q-ST-60-14C, EEE Components Relifing procedure - October 1, 2019

0 comments on Main changes in ECSS-Q-ST-60-14C, EEE Components Relifing procedure