Space and HI-REL Assembly

- Posted by doEEEt Media Group

- On March 12, 2020

- 0

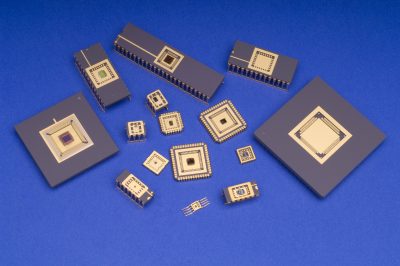

Alter Technology (formerly Optocap), is a leader in the design, manufacture and test of High Reliability Micro and Optoelectronics modules for Harsh Environments. We have experience in a number of high reliability and harsh environment markets such as Aerospace & Defence, Space, Oil & Gas

Focussed areas of excellence

MIL-STD-883 and ESCC Standards

- Die Attach

- High performance epoxies

- Solder die attach

- Pick from film/frame, waffle or gel pack.

- Flip-chip attach & Au stud bumping

- Wire Bond

- 17 to 50um Au ball bonding

- Al wedge bonding

- Hermetic sealing

- Sealing

- Seam seal

- TO Can projection weld

- Solder seal

- Vacuum packaging

- Fine and gross leak test

- QC checks

- Die shear and wire strength tests

- Real-time X-RAY

- Fine and gross leak test

- Placement accuracy measurements

Test & Screening – Alter Technology

- Parts Engineering

- Component Testing

- EEE Procurement

- Certification

- Radiation testing

- Burn-in & Life Test

Contact us for more information

Latest posts by doEEEt Media Group (see all)

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Space and HI-REL Assembly