Chip on Board

- Posted by doEEEt Media Group

- On March 12, 2020

- 0

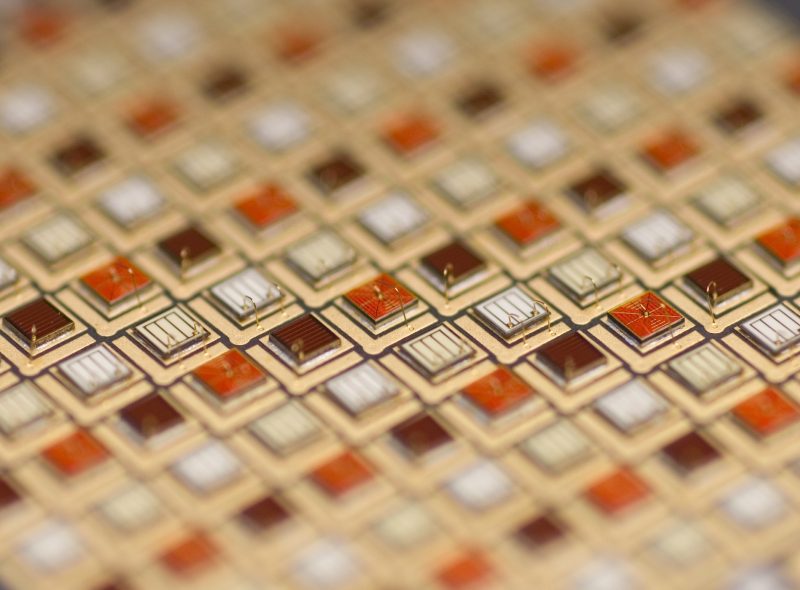

Chip on Board assembly is the process whereby a bare semiconductor die is mounted on a printed circuit board or substrate using conductive or non-conductive epoxies. For applications that require very high thermal and electrical conductivity, we have many semi-sintering epoxies which lend themselves to chip-on-board assembly. Die are typically electrically connected using Au ball bonding or Al Wedge Bonding.

Alter Technology UK can also attach a die face-down onto a PCB using flip-chip technology, either using solder balls pre-applied at a wafer level or our in-house stud bumping process. The die is then protected using a glob top or Dam/Fill encapsulation process. Most chip-on-board assembly can also be combined with our fast-turnaround service.

For more specialist requirements, please contact Alter Technology UK for a detailed technical review.

Save time searching the EEE components of your design in doEEEt database.

Contact us for more information

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

- ALTER SPACE TEST CENTER: testing approaches for New Space - September 30, 2024

0 comments on Chip on Board