The TAB®-Long-Term Conservation Method is of decisive importance for wafers to ensure long-term processability and functionality as well. Due to the drastic reduction of aging mechanisms is possible to store wafers for up to 50 years without significant quality losses, depending on the initial condition.

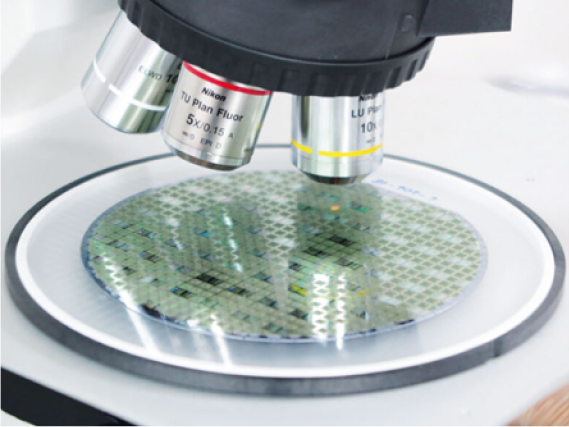

Handling and optional further processing of the goods (e.g. wafer dicing, bonding and packaging) in a clean room to prevent contamination, if required, offers the highest quality standards throughout the entire storage process. In addition, an optical inspection, even of wafers if so, required by the customer, enables the clear identification of contaminations, cracks or discoloration.