Varistors for Automotive Ethernet

- Posted by doEEEt Media Group

- On May 4, 2021

- 0

AVX Technical Paper

When it comes to protecting electrical equipment from high voltage transients, metal oxide varistors (MOVs) are among the most popular choices. Automotive single-pair ethernet accomplishes high data transfer demand while still adhering to robust EMI and EMC requirements. This paper is written by Akihiro Kado and Michael Kirk from AVX Corporation to discuss the capabilities of varistors and their suitability for automotive ethernet applications.

Introduction

The ubiquity of high-performance sensor systems in modern automobiles (particularly electric and self-driving vehicles) has created immense pressure to develop automotive local area networking (LAN) solutions that offer high bandwidth, low latency, and low cost. Unfortunately, traditional wiring harnesses have become too heavy and complex to support these data and power needs.

To date, wired ethernet has taken center stage in this quest, with manufacturers offering physical layer (PHY) devices for single twisted pair data transmission that complies with the latest IEEE 802.3 standards. In particular, considering the data demands of backup video cameras, self-driving cameras, and LIDAR/RADAR object detection systems, the 802.3cg standard has become commonplace, offering 10 Mbps over a 25 m distance using a single twisted pair. Furthermore, in addition to data transfer, the same twisted pair can provide sensor subsystems power over ethernet (PoE) techniques. Most importantly, automotive single-pair ethernet accomplishes this while still adhering to robust EMI and EMC requirements.

The Importance of Varistors

When it comes to protecting electrical equipment from high voltage transients, metal oxide varistors (MOVs) are among the most popular choices. These devices exhibit a reduction in resistance at high voltages, effectively absorbing the voltage spike and dissipating the energy as heat. Typical varistors are specified by their maximum voltage, the energy they can dissipate, their capacitance, and response time. When protecting integrated circuits on high-speed data lines, such as an automotive ethernet PHY, capacitance becomes the most critical parameter because it can directly affect the data waveform. Unfortunately, low capacitance generally implies a small physical size and low voltage and energy ratings. Thus, achieving adequate ESD and EMI protection in a small form factor is a primary challenge for manufacturers today.

AVX Varistors

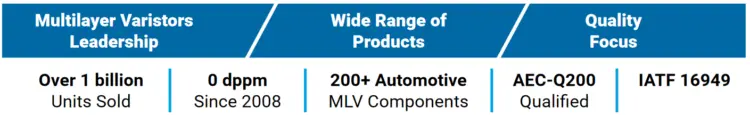

AVX began shipping a selection of multi-layer varistors (MLV) in 1988 and entered the automotive supply chain in 2001. AVX has adopted bismuth oxide (Bi2O3)-based construction for its high reliability and has resulted in zero defective parts per million quality record since 2008. In addition, these devices meet the strict automotive quality standards (AEC-Q200, for example) and, as such, are an ideal choice for protecting automotive Ethernet circuits.

Figure 1: AVX Varistor History and Specifications

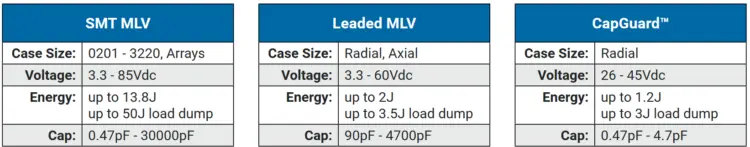

Depending on the specific requirements for size, capacitance, and energy protection, several different MLV devices are used to choose from. Three popular AVX lines are shown in figure 2.

Figure 2: AVX lines of multi-layer varistors

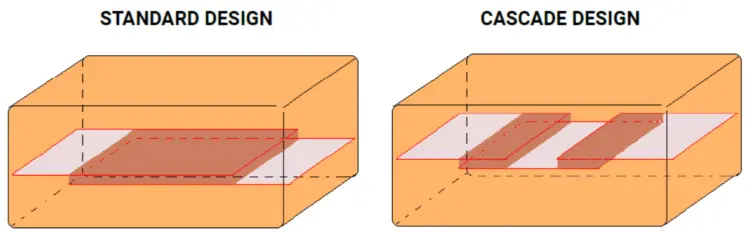

AVX also offers a specific lineup of MLV’s called “Antenna PowerGuard,” which provides ultra-low capacitance and tight tolerance for use in RF circuits, sensors, and high-speed data lines. This is achieved through their cascade structure (shown in figure 3), which maintains ESD resistance while reducing total overall capacitance. As a result, these devices are an ideal choice for protecting single-pair ethernet data lines in automotive applications.

A Competitive Comparison

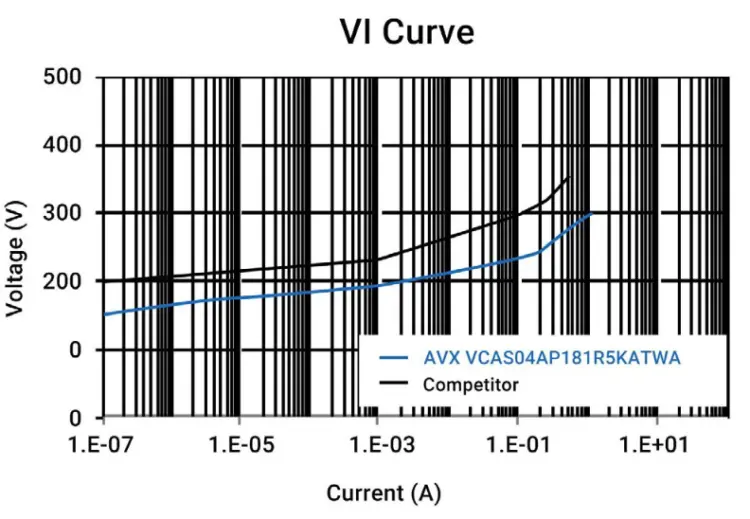

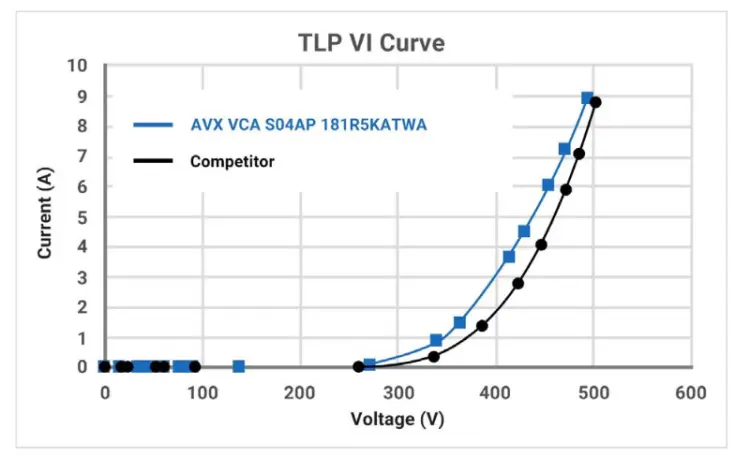

To demonstrate the Advantage of Antenna PowerGuard varistors in automotive ethernet applications, an AVX device (VCAS04AP181R5KATWA) was tested next to a competitive product with similar electrical specifications. The I-V curve for the two devices is shown in figure 4, where it can be seen that the AVX device offers superior clamping voltage across the entire range tested. Similarly, in transient tests of 100 ns voltage pulses with 200 ps rise times, the AVX device consistently outperforms the competition with a lower clamping voltage.

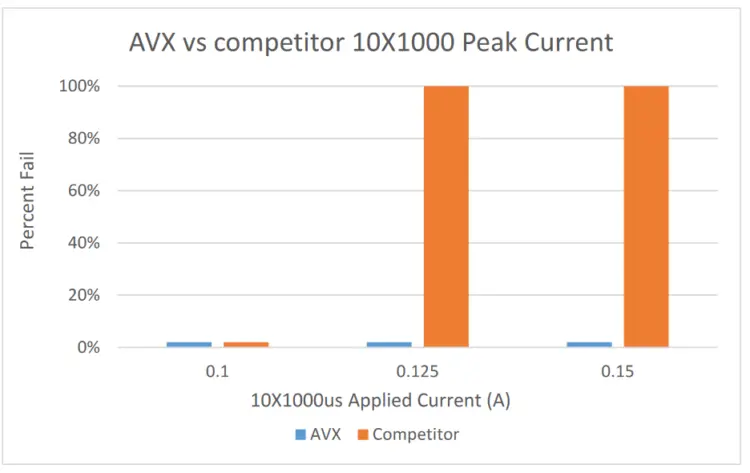

Transient energy testing with the 10X1000us pulse shows the ability of the AVX OPEN alliance varistor to suppress a high energy pulse. The AVX design provides higher protection to the circuit than the competitive varistor device.

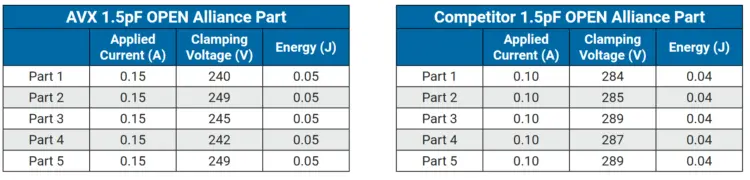

Figure 6 shows the AVX varistor’s ability to suppress a transient with a higher applied current, 0.15A for AVX and 0.1A for the competitor without failing. Figure 7 shows the lower clamping voltage with higher transient energy suppressed between the AVX and competitor parts. The AVX device provides improved protection as it is capable to withstand higher energies while better suppressing the transient pulse in the circuit.

Source: AVX Corporation

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Varistors for Automotive Ethernet