Understanding the Importance of Resistors in SMPS

- Posted by doEEEt Media Group

- On July 11, 2023

- 0

This Bourns application article explains basic resistor considerations and the importance of resistive components in SMPS switch mode power supplies.

Switched-Mode Power Supplies (SMPS) are widely used in various electronic devices and systems, from consumer electronics to industrial applications. These power supplies rely on various electronic components for efficient and reliable power conversion.

Among these components, resistors play a critical role in SMPS operation and performance.

Understanding the Basics of SMPS

Before we dive into the details, let’s briefly review the fundamentals of SMPS. A Switched-Mode power supply converts electrical power from one form to another through switching devices (typically transistors) that rapidly switch between conducting and non-conducting states. This switching action allows for efficient power conversion and regulation, enabling SMPS to provide stable DC voltages at varying load conditions.

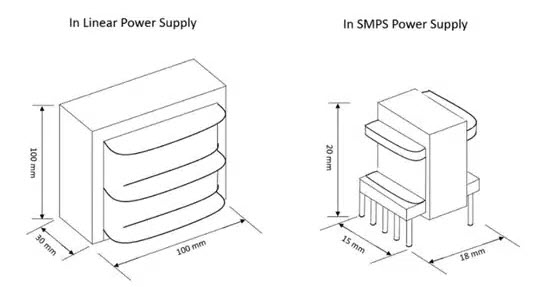

Figure 1. Transformer size comparison between a conventional power supply and an SMPS power supply.

Many different topologies are used in SMPS designs, including forward, flyback, boost, buck, buck-boost, half-bridge and full-bridge.

The flyback topology is the most popular and is commonly used in consumer and industrial SMPS-based applications, such as mobile phone chargers, portable power banks, laptop chargers or AC-DC converter applications.

Switched-Mode Power Supplies (SMPS) offer a highly efficient power technology that enables systems to operate with a wider input voltage range and a longer output voltage holding time than conventional linear power supplies. The result is that customers can build smaller and lighter applications. Supporting SMPS-based designs are new, smaller form factor transformers and resistors (such as the 0201 or 01005 size components shown in Figure 1.

Providing a Foundation for SMPS Operation

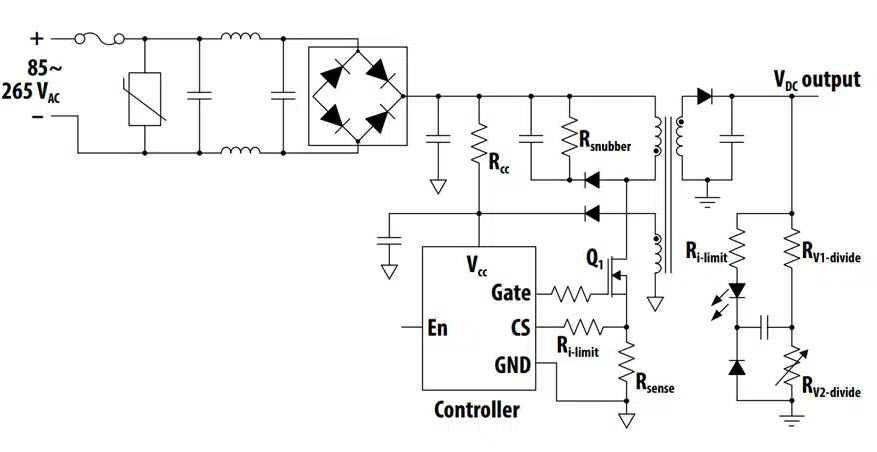

Resistors are passive electronic components that regulate electronic circuits’ current flow and voltage levels. Resistors provide the following functions in an SMPS, as illustrated in Figure 2. Figure 2 illustrates a flyback design and how each resistor type has its function, which must be considered for the circuit to perform properly.

- Voltage Dividers and Feedback Networks: Resistors are frequently used in voltage dividers and feedback networks to establish reference voltages, regulate feedback signals, and ensure stable operation of SMPS controllers. These resistive networks contribute to the accurate monitoring and control of output voltages and currents, ultimately helping to improve the overall performance and reliability of the power supply.

- Current Sensing and Limiting: SMPS employs resistors with low resistance values as current-sensing elements. The control circuitry can accurately sense and regulate the output current by measuring the voltage drop across these resistors. Additionally, resistors can be combined with other components to provide overcurrent protection, preventing damage to the power supply and connected devices.

- Snubber Circuits: Switching transistors in an SMPS can generate high-frequency noise and voltage spikes. To mitigate these undesirable effects, snubber circuits are employed. Resistors, in conjunction with capacitors, are used to design snubber networks that suppress voltage transients and protect sensitive components from voltage spikes, thus enhancing the longevity and reliability of the power supply.

- Filtering and Damping: Resistors are integral to filtering and damping functions within an SMPS. They are used in conjunction with inductors and capacitors to construct filters that attenuate high-frequency noise, ripple and other disturbances, helping to ensure the clean power delivery to the load.

Start-Up and Soft-Start Mechanisms: During start-up, the circuits in an SMPS often employ resistors to control the charging and discharging of capacitors, establish timing delays, and implement soft-start mechanisms. Soft-start circuits gradually ramp up the output voltage to prevent inrush current and voltage overshoot, reducing stress on components and increasing the lifespan of the power supply.

Figure 2. Illustration of SMPS flyback power topology.

Resistor Rcc is in place to withstand high voltage from the bridge rectifier and is used in the pre-charging phase to protect the controller. For this function, the Bourns® Model CHV and CHV-A Series feature high voltage withstanding capability, up to 3 kV operating voltage and compliance with UL 1676 and UL 62368-1 standards that help ensure higher reliability.

Resistors for Rsnubber are employed to protect the transformer due to countless continuous large surge voltages generated when MOSFET Q1 is in switching mode. The resistance value of the Rsnubber function needs to be determined by the leakage inductance of the transformer’s switching frequency, clamped voltage of the MOSFET flyback voltage, and the current flow going through the primary side of the transformer, which are all dependent on the customer’s requirements. Bourns® Model CMP, CMP-A, CHP and CHP-A Series offer high surge capability, low TCR and a wide resistance range suitable for the snubber function. For instance, the maximum surge capability of the Model CHP Series in 100 µs is 800 W, and the Model CMP Series supports up to 1 kW in 100 µs. If a higher surge voltage capability is required, Bourns® Model PWR163, PWR263S, PWR220T or PWR221T Series are good options for this application as the maximum peak pulse power of the PWR Series is up to 5 kW in 100 µs.

The Rsense function resistors are used for monitoring current flow through the primary side of the transformer during MOSFET Q1 switching. Depending upon how the controller is designed for the application, it will sense voltage from Rsense and determine when to turn Q1 ON or OFF to protect the AC-DC converter and load connected with the output terminal. The resistance value and power rating are determined by the current flow through the transformer, switching frequency, MOSFET’s duty cycle, and the controller’s sense capability.

Resistors for the Ri-limit function limit input current for protecting the controller and thus require an accurate resistor to help ensure the most effective protection. To fill this need, Bourns offers 0.5 % tolerance resistors, such as the thick film Model CRM Series.

In addition, Rv1-divide and Rv2-divide resistors are utilized to divide output voltage feedback to the controller, which also requires more accurate resistors. Again, Bourns® Model CRM Series, providing 0.5 % resistance tolerance with 100 PPM/˚C in a small 0603 package size, is an excellent choice for Rv1-divide and Rv2-divide. If the engineer is designing for user flexibility, the Rv2-divide can be a variable resistor to cater to different controllers. Ideal solutions are the Bourns® Model 3313 and 3314 Series Trimpot® Trimming Potentiometers offered in a single-turn, AEC-Q200 compliant compact SMD footprint, with 0.1 % adjustability of the voltage divider to meet the requirements for this application.

Conclusion

The “Understanding the Importance of Resistive Components in SMPS” explains the crucial role played by resistors in the operation and performance of Switched-Mode power supplies. From voltage regulation and current sensing to snubber circuits and soft-start mechanisms, resistors enable precise control, stability and protection in SMPS designs.

By understanding the significance of resistors and their various functions in an SMPS, engineers and designers can make informed choices when selecting these required components. Doing so will help them optimize the overall performance and reliability of their SMPS design.

- Space-Grade components available for immediate delivery - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

0 comments on Understanding the Importance of Resistors in SMPS