PolyCharge Double Energy and Increase Operating Temperature

- Posted by doEEEt Media Group

- On October 12, 2020

- 0

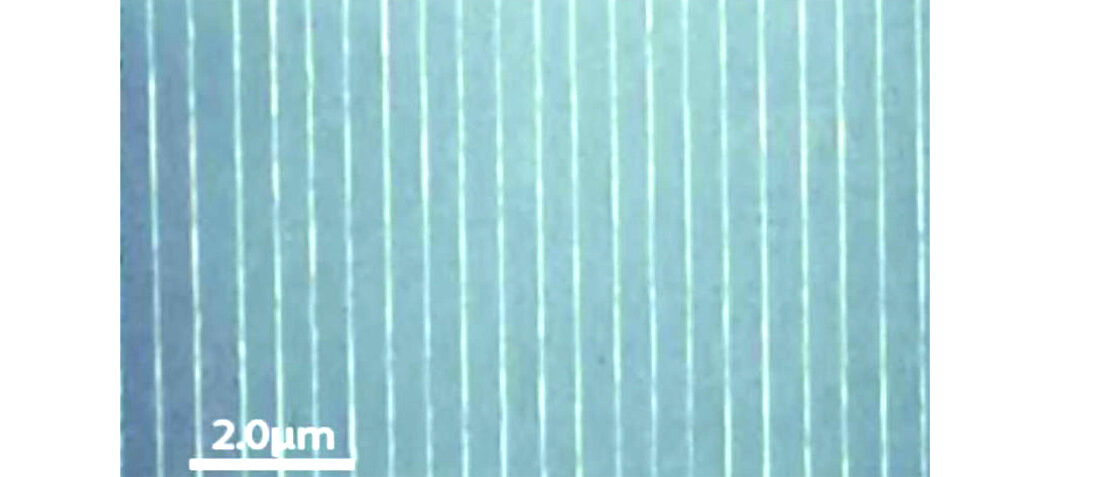

PolyCharge NanoLam™ technology is a proprietary process for producing high energy density capacitors with high temperature handling capabilities. NanoLam™ capacitors utilize super-thin polymer dielectric layers that are formed inline with the metal electrode deposition process. The result is a self-supported, large area, capacitor composite that is segmented into individual self-healing capacitors. All of this happens in one machine – eliminating the need for extruded films, film metallization, and capacitor winding.

PolyCharge has addressed capacitor size and thermal limitations of metallized polypropylene (PP) DC-link capacitors, used in electric vehicle inverters, by developing solid state, high energy density capacitors, comprising 1000s of nano-thick, cross-linked polymer dielectric layers. PolyCharge NanoLam™ capacitors are ideal for higher voltage applications where space, weight, and high temperature tolerance are demanded.

NanoLam™ capacitors represent a transformational and potentially disruptive process for making polymer capacitors. In a single process step, a large area nanolaminate composite is produced, which is segmented and processed into individual capacitors that have low ESR and ESL, operating temperature >125°C, high current carrying capacity, excellent self-healing properties, and energy density at least double that of existing PP capacitors.

PolyCharge was formed by Sigma Technologies in September 2017 to develop and commercialize its NanoLam™ technology for electric drive vehicles, renewable energy inverters, medical, aerospace, and industrial mobility applications. The company’s headquarters, engineering, and product development center are located in Tucson, Arizona, USA. Delphi Technologies PLC a global leader in vehicle propulsion, announced an investment in PolyCharge America, Inc. in January 2018 to commercialize the new capacitor technology.

“PolyCharge is well-positioned to lead in the development of next-generation capacitor products for vehicle electrification and other applications where reductions in weight and volume, as well as performance in harsh operating environments, are required.”said Dr. Angelo Yializis, Chief Executive Officer of PolyCharge.

More details about the state of the art in the technology will be disclosed in technical paper “A Disruptive Nano-laminate Polymer Capacitor Technology for Electric Drive Applications” presented by Dr. Yializis during the international PCNS Passive Conference Networking Symposium 10-13th September 2019 in Bucharest, Romania here ⇐

Source: PolyCharge, EPCI

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on PolyCharge Double Energy and Increase Operating Temperature