Kemet Continue to Toughen Up Polymer Tantalum Capacitors

- Posted by Kemet Electronic Corporation

- On October 17, 2020

- 0

New materials and manufacturing processes enable polymer tantalum capacitors to pass automotive AEC-Q200 stress test requirements, as well as specific electrical transient tests. Although the market supply chain challenges with high CV MLCC‘s availability and new automotive requirements with electrification, digitalization, and autonomous driving are bringing new opportunities.

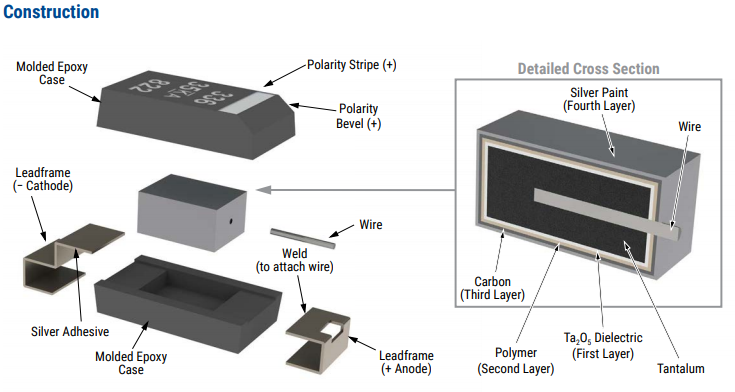

Tantalum Polymer SMD construction is shown in Figure 1. The anode body is a sintered tantalum powder, the dielectric is a thin film of Ta2O5 generated by electrochemical oxidation, and the cathode is a highly conductive polymer layer deposited in the oxide layer. The contact layers consisting of carbon and silver require prior assembly and molding protection. Tantalum Polymer SMD parts are polar capacitors; therefore, is important to pay attention to the polarity marking in the component. Reverse polarity is permitted only up to values indicated in this paper. Although, several application guidelines should be considered by the designers.

Figure 1. Basic Construction of Tantalum Polymer SMD

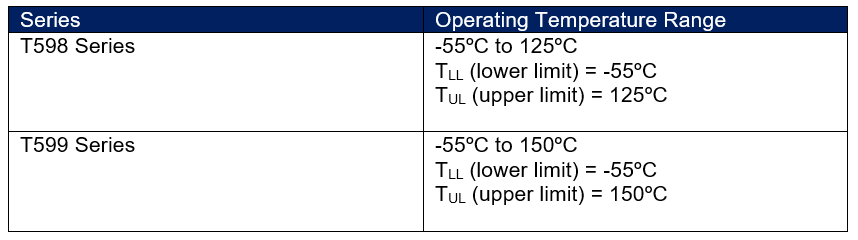

KEMET Automotive grade products are designed by Tantalum Polymer SMD T598 (125ºC) and T599 (150ºC) series.

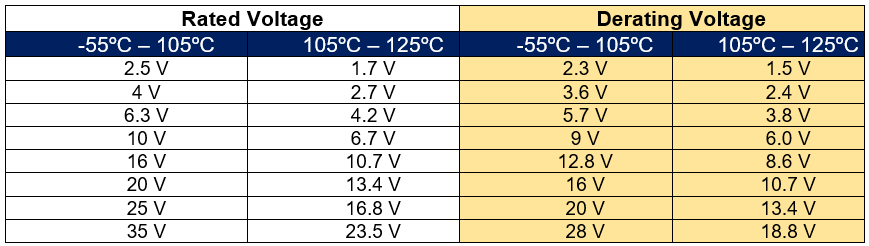

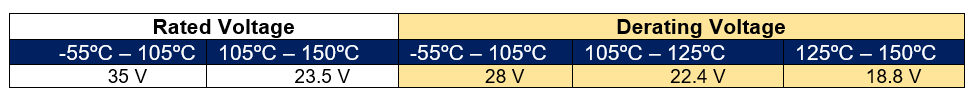

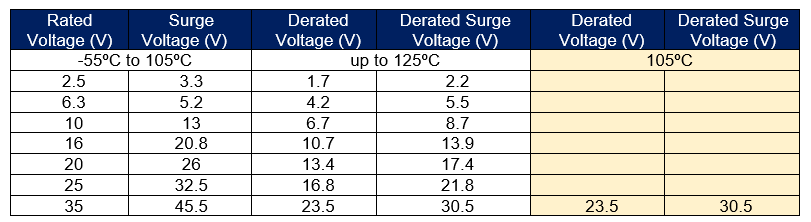

The range for voltage is 2.5 V to 35 V Rated Voltage (Ur), and is defined as maximum peak DC operating voltage from -55ºC to 105ºC for continuous duty. Above 105ºC the voltage is derated linearly to 0.67 Ur up to maximum operational temperature. See Table 2a and 2b.

Tantalum polymer SMDs are solid state capacitors that demonstrate no wear out mechanism when operated within their recommended guidelines. While they can be operated at full rated voltage, most circuit designers seek a minimum level of assurance in long term reliability, which should be demonstrated with data. A voltage derating can provide the desired level of demonstrated reliability based on industry-accepted acceleration models. Since most applications do require long term reliability.

KEMET recommends that designers consider a voltage derating, according to Table 2a and 2b, for the maximum steady state voltage.

Table 2a. Derating T598 Series

Table 2b. Deratin599 Series

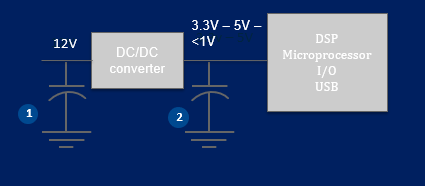

In Automotive applications, as described schematically in Figure 2, the output position component (capacitor 2) selection follows Table 2a and 2c depending on the mission profile/temperature requirements. For the 12 V line, KEMET’s recommendation is, at minimum, a 35 V rated voltage capacitor taking into consideration the existing ISO Pulse requirements defined by ISO7637 Specification.

Figure 2. Schematic diagram of an Automotive Applications

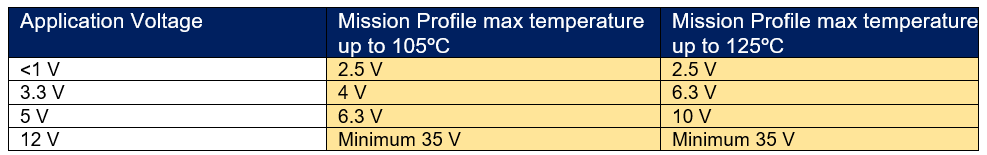

Table 2c represents the recommended capacitor per application voltage organized by the maximum mission profile application temperature.

Table 2c. Application voltage – Recommended Capacitors

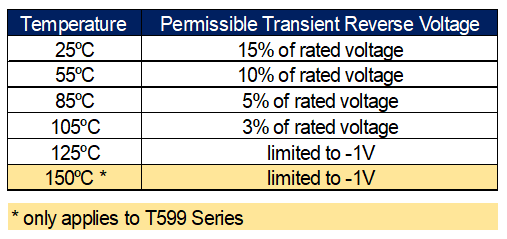

Tantalum Polymer capacitors are polar devices and may be permanently damaged or destroyed if connected to the wrong polarity. The positive terminal is identified by a laser marked stripe. The capacitors will withstand a small degree of transient voltage reversal for short periods, as shown in Table 3. Please note these parts may not be operated continuously in reverse, even within these limits.

Table 3. Maximum Permissible Transient Reverse Voltage

In the 12 V line, special protection is required to protect the component against transient negative pulses.

The Tantalum Polymer SMD automotive series is fully qualified according to the AEC-Q200, revision D from June 2010, and follows the Table 1 qualification sample size requirements and Table 2 table of methods referenced – Tantalum and Ceramic Capacitors. The T598 series offers extended Endurance Life tests up to 2,000 hours demonstrating robust design capabilities.

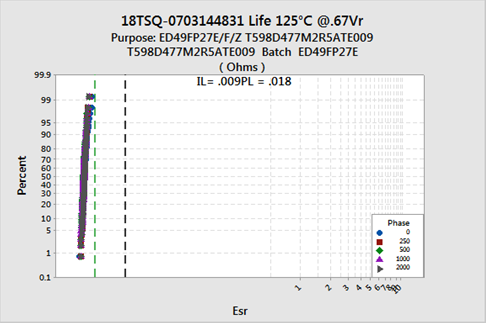

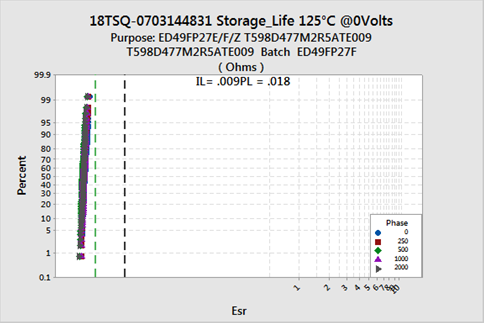

In an effort to support new Advanced Driver Assistant Systems (ADAS) and comply with the new ultra-extended mission profiles, a new 7343-31 capacitor with 470 uF 2.5 V with 9 mOhm (https://api.kemet.com/component-edge/download/specsheet/T598D477M2R5ATE009.pdf) was released to the market. The qualification process was performed with a maximum operational temperature of 125ºC up to 2,000 hours. The critical ESR stability at endurance and storage evaluation is shown in Figure 3a and 3b. In both tests, the post measurements show that all capacitors keep an ESR level within 9 mOhm.

A surge voltage is a maximum voltage (peak value) that may be applied to the capacitor. The surge voltage must not be applied for periodic charging and discharging over the course of normal operations and cannot be part of the application voltage. Surge voltage capability is demonstrated by the application of 1,000 cycles at operating temperature. The parts are charged through a 33 Ohm resistor for 30 seconds and then discharged through a 33 Ohm resistor for each cycle. Table 4 shows the applied maximum surge overvoltage for T598 and T598 series.

Figure 3a. Endurance 125ºC / 0.67 Ur up to 2,000 hours – 470 uF 2.5V – 9 mOhm

Figure 3b. Storage 125ºC / 0 Vr up to 2,000 hours – 470 uF 2.5 V – 9 mOhm

Table 4. Maximum Surge Overvoltage

The design of T598/T599 Series on the input side requires an explanation of the technological differences with the old Ta-MnO2 products. During recent years, KEMET has made efforts to clarify that Tantalum Polymer capacitors typically offer a benign failure mode, mitigating ignition due to the absence of oxygen.

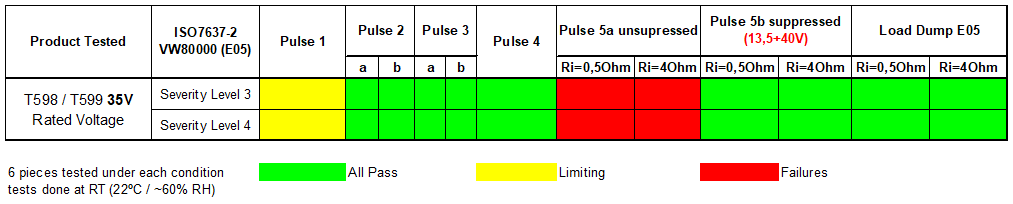

In addition, extensive tests were performed based on the:

ISO7637-2 Road vehicles – Electrical disturbances from conduction and coupling. Part 2: Electrical transient conduction along supply lines Special Load Dump testing E05 according to the VW80000, issue 06-2013 – Electric and Electronics Components in Motor Vehicles up to 3.5t.

Results are summarized in Table 5:

Table 5. Summary of ISO7637-2 and VW80000-E05 Load Dump

We concluded that for the 35 V rated voltage part numbers no failures were created on Pulses 2a, 2b, 3a, 3b, 4, 5b suppressed, and E05. The application attention is required with:

Pulse 1 – The 1 Reverse Pulse requires reverse voltage protection with a maximum of -1 V

Pulse 5a – The 5a pulse limitation requires up the front definition of the pulse shape and parameters for an alternator with centralized load dump suppression. In most new alternators, the load dump amplitude is suppressed (clamped) by the addition of the limiting diodes. All evaluations with a maximum peak of (13.5+40) V pass the acceptance criteria.

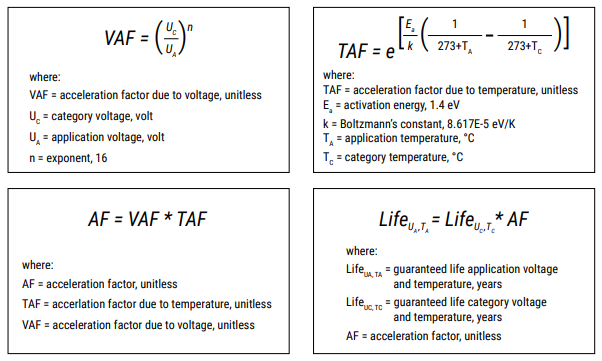

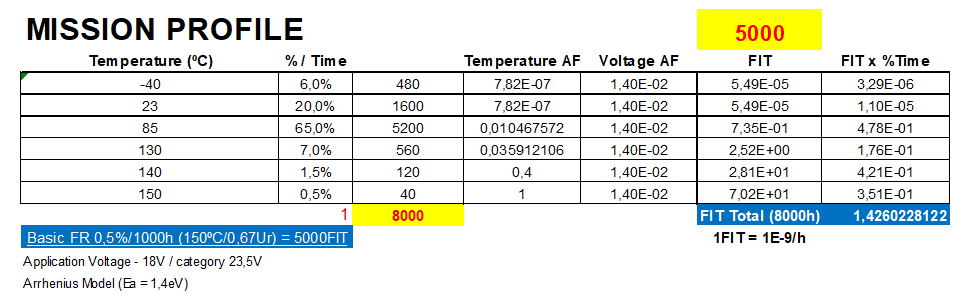

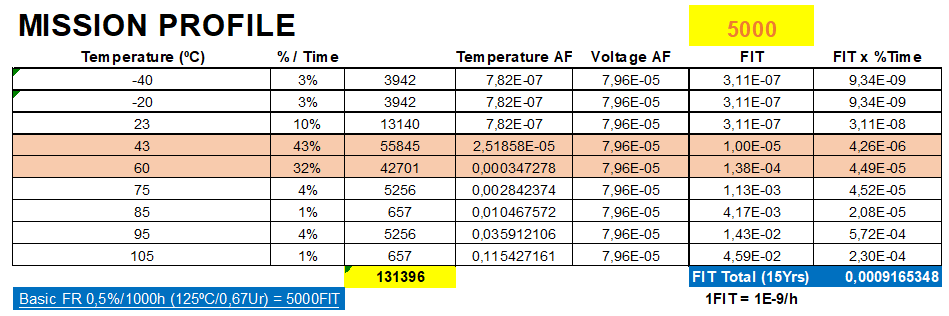

An important application requirement is the validation of the mission profile. Tantalum Polymer SMD capacitors have an average failure rate of 0.5 %/1,000 hours at category voltage, UC, and category temperature, TC. These capacitors are qualified using industry test standards at UC and TC. The minimum test time (1,000 hours or 2,000 hours) is dependent on the product series. The actual life expectancy of polymer capacitors increases when application voltage, UA, and application temperature, TA, are lower than UC and TC.

As a general guideline, when UA < 0.9 * UC and TA < 85°C, the life expectancy will typically exceed the useful lifetime of most hardware (> 10 years). The lifetime of a polymer capacitor at a specific application voltage and temperature can be modeled using the equations below:

A failure is defined as passing enough current to blow a 1-Amp fuse. The calculation below is an estimation based on empirical results and is not a guarantee.

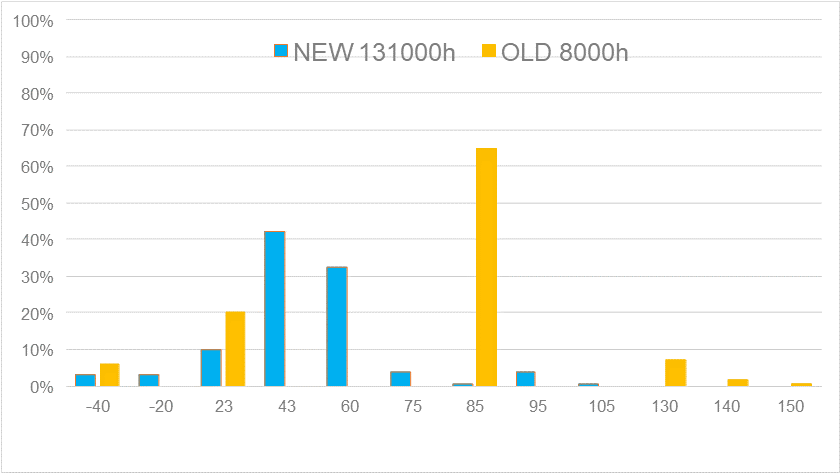

The existing automotive Tantalum Polymer SMD series offer an excellent solution for bulk capacitance requirements and high-reliability capability against typical mission profiles. See Figure 4.

Histogram Reference Example

During the mission profile validation, we determine the estimated FIT based in the given conditions, from the examples described above we can estimate from the Old Mission Profile and New Mission Profile that the Automotive Tantalum Polymer SMD products are a viable option. See Figure 5a and 5b.

Mission Profile Validation – Old Mission Profile Example

Figure 5b. Mission Profile Validation – New Mission Profile Example

- Decoding The DC-Link - June 8, 2022

- High Reliability: Tantalum Capacitors on the Front Lines of Defense - June 3, 2022

- One Turn Inductors Explained - March 24, 2022

0 comments on Kemet Continue to Toughen Up Polymer Tantalum Capacitors