How to read a capacitor data sheet

- Posted by doEEEt Media Group

- On November 7, 2020

- 0

Capacitors are used in electronic circuits for a wide range of applications including coupling, timing, filtering, decoupling, and waveshaping. These passive components come in a wide array of shapes, sizes, and designs, and it is usually not easy to identify a component that meets the specific requirements of an application. In most electronic circuits, the overall performance of a circuit is greatly determined by the choice of capacitors.

Identifying a component that meets the requirements of an application is, therefore, a critical step in the designing of electronic circuits. The performance characteristics of any electronic component are provided by manufacturers in product datasheets. This makes a data sheet one of the most useful resources for circuit designers and engineers.

Despite their usefulness, data sheets can contain a lot of information making it difficult for users to extract the details they require for a given component. A typical capacitor datasheet provides the following information about a component:

- Performance characteristics

- Typical applications

- Limitations of a component

In this guide, we will provide you with tips that can help you to get the most from a capacitor’s data sheet. So, where do you get the right data sheet from? Capacitor data sheets are usually available on manufacturer’s website. Alternatively, you can soon easily download any capacitor data sheet from here. It is important to double check the model number and date of publication to make sure that you are using the right data sheet.

Capacitor data sheets, much like other product data sheets, vary in design and layout depending on the manufacturer. In this guide, we will explore different sections of a typical capacitor data sheet.

Overview

This section summarizes characteristics, features, and typical applications of a component.

Applications

Most manufacturers provide examples of applications that a capacitor can be used for. This section helps circuit designers to find components that are suitable for their applications with ease. This list is usually not exhaustive.

Electrical characteristics

This section provides electrical parameters that are of interest to circuit designers. Some parameters are provided directly in the data sheet while others are not. It is important to note that most of these parameters are given at specific conditions.

Voltage

This is one of the key parameters to consider when selecting a capacitor for your application. For most types of capacitors, manufacturers specify voltage characteristics in terms of rated voltage, surge voltage, operating voltage, transient voltage, reverse voltage, and ripple voltage. The rated voltage specifies the maximum peak voltage value that may be applied between the terminals of a component. This nominal voltage is usually indicated on a component by the manufacturer. In comparison, the operating voltage specifies a range of acceptable voltages that may be applied to a component without damaging it.

Capacitance

Most capacitor data sheets specify the capacitance of a component in terms of rated capacitance, AC/DC capacitance, and charge-discharge proof properties. Details on how the capacitance of a component varies with temperature and frequency are usually provided under this subsection.

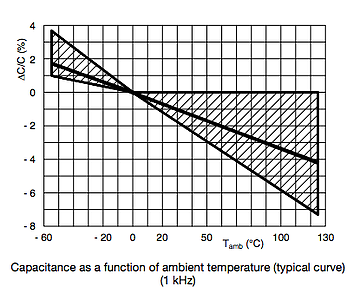

For some types of capacitors, the capacitance of a component can change significantly over time. The irreversible changes mainly depend on the characteristics of the dielectric material used. The rate at which the capacitance of a component drifts is dependent on the temperature variations that a component is exposed to. The average variation in capacitance over a temperature range is usually described in terms of temperature coefficient. In most data sheets, these variations are provided in form of performance curves.

Example Cap vs. Temp Curve. Image source www.vishay.com

Equivalent series resistance (ESR)

For a typical equivalent circuit diagram, the equivalent series resistance is the resistive component of the circuit. Just like capacitance and dissipation factor, this parameter is significantly dependent on variations in temperature and frequency. The ESR and the dissipation factor of a capacitor are closely related. In most data sheets, the ESR characteristics of a component are provided in form of performance curves.

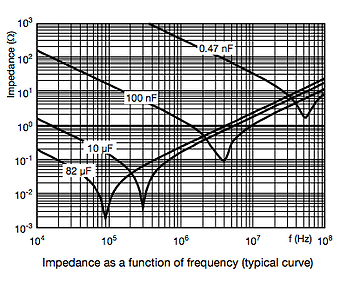

Impedance

The main contributors to the total impedance of a capacitor vary depending on the capacitor technology. The magnitude of impedance depends on the individual reactive and resistive components of a capacitor’s equivalent circuit diagram. The three contributors-inductive reactance, capacitive reactance, and equivalent series resistance- vary depending on the frequency of operation. The last two are also dependent on temperature. In most data sheets, the impedance characteristics of a capacitor are usually provided in form of performance curves.

Example Impedance vs. Frequency Curve. Image source www.vishay.com

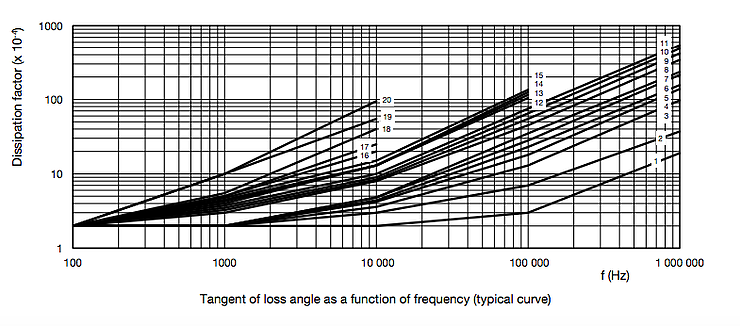

Dissipation factor (tanδ)

This electrical parameter describes the relationship between the effective power and the reactive power when a sinusoidal voltage is applied to a component. If we consider a typical equivalent circuit diagram, this parameter relates the capacitive reactance component and the equivalent series resistance. The variation of this parameter with frequency and temperature is usually specified in the data sheet, usually in form of performance curves.

Image source: www.vishay.com

Equivalent series inductance (ESL)

ESL is one of the key components of a basic equivalent circuit diagram of a typical capacitor. This parameter is primarily determined by the internal design of a component and its terminal configuration. The equivalent series inductance of a component is relatively independent of temperature and frequency.

Leakage current

This parameter depends on many factors including the design of a component, internal temperature, and applied voltage. The storage time and conditions significantly determine the initial leakage current of a component. In most data sheets, the leakage current characteristics of a capacitor are provided in form of performance curves.

Ripple current

A current flows through a device when an AC voltage is applied, and it is equivalent to the root-mean-square value of the pulsating current. This current causes power losses and determines the self-heating properties of a component. For most capacitors, the circuit designer is expected to calculate the maximum ripple current.

Some of the factors that one should consider when determining the maximum permissible current value include ambient temperature, thermal resistance, equivalent series resistance, and cooling methods used. In most data sheets, manufacturers provide rated ripple current value at specific temperature and frequency conditions.

Breakdown strength

This parameter is greatly determined by the design of a component and varies from one type of capacitor to another. For aluminum electrolytic capacitors, most manufacturers use insulating sleeves to boost breakdown strengths.

Temperature characteristics

Most performance parameters of a capacitor are significantly dependent on the temperature at which a component is operated. The data sheet specifies the temperature range for which a component is designed. It also provides information on how changes in temperature affect other parameters, usually in form of performance curves.

Other performance characteristics that are of interest to circuit designers include the following:

- Insulation resistance

- Insertion loss

- Aging rate

Performance graphs

Most capacitor parameters vary depending on conditions such as temperature and frequency. For such parameters, manufacturers use performance curves to describe the characteristics of a component. The circuit designer can determine a specific value for such a parameter by reading the value that corresponds to conditions at which the component will be used.

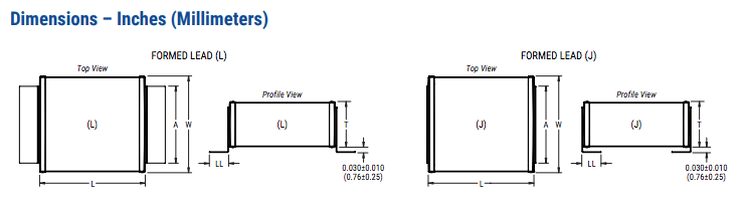

Dimensions

When designing a circuit, one of the key things to consider is the size of a component. Manufacturers provide this information to enable you to select a component that meets the space requirements of your circuit. The size is usually specified in both inches and millimetres.

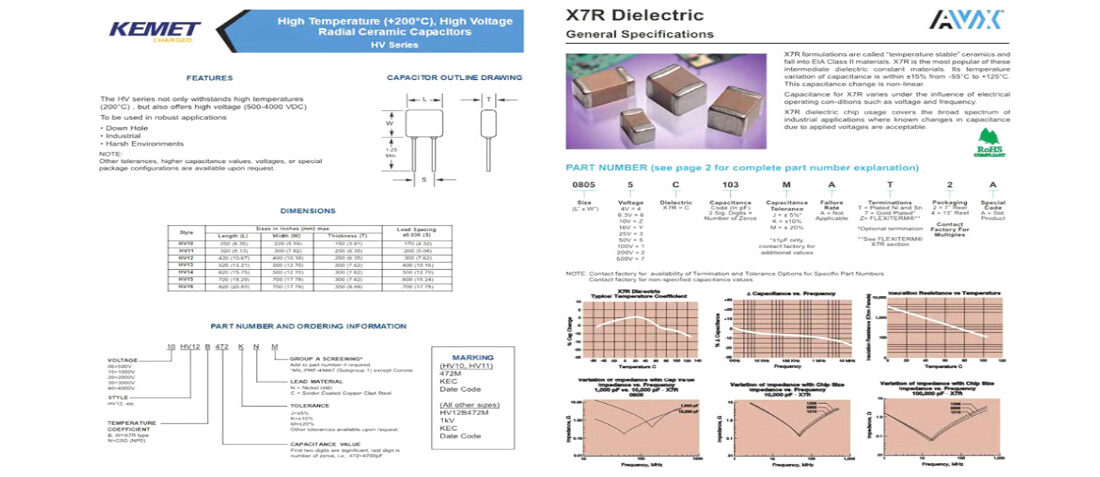

Image source: kemet.com

Construction

For some applications, the circuit designer may be interested in the construction technology of a component. This section provides construction details that could be of interest to circuit designers.

Mechanical stress

If you are intending to use a capacitor in an application where it may be exposed to shock and vibrations, then it is critical to consider its resistance to mechanical stress. Some of the parameters that are provided in data sheets to help you assess the suitability of a component for such an application include operating altitude, vibration resistance, and robustness of terminals and leads.

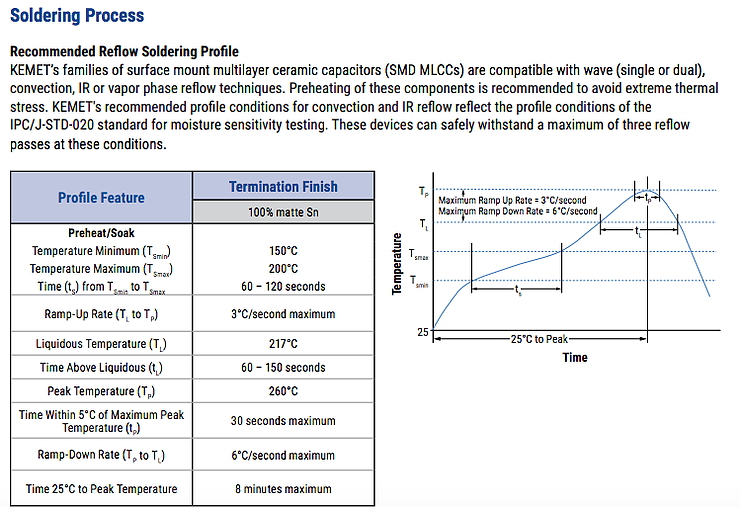

Soldering

The performance characteristics of a capacitor can be significantly affected if the soldering requirements specified by the manufacturer are not met. Exposing a capacitor to excessive temperatures, longer soldering time, and applying excess soldering material are some of the things that can lower the performance of a component. A typical data sheet provides guidelines on soldering procedure, soldering conditions and limitations, and recommended soldering products. This information is provided for capacitors that require soldering.

Image source: www.kemet.com

Mounting

An electronic circuit can fail if a component is not mounted correctly. To ensure that your circuit is performing optimally, capacitor manufacturers provide mounting guidelines in component data sheets. In most cases, multiple recommended mounting positions are provided to allow you flexibility in your design. It is always important to pay attention to cautions provided in a data sheet before attempting to mount a component. In addition to mounting positions, component manufacturers also specify recommended torques under this section.

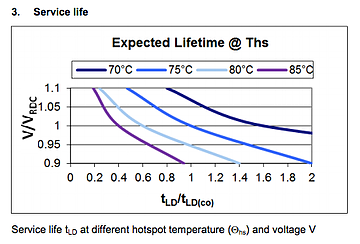

Cooling

Some types of capacitors such as aluminum electrolytic capacitors produce heat in the windings. Excess heating can significantly affect the ripple current and service life of a component. For components that are likely to generate considerable amounts of heat, natural convection is not sufficient, and it is necessary to provide external cooling in order to achieve optimum performance. Some of the most common methods of cooling capacitors include using forced ventilation or heat sinks. It is common for manufacturers to specify in datasheets whether external cooling is required or not.

Climatic category

The performance characteristics of a capacitor are significantly dependent on the climatic conditions under which a component is used. One of the most important environmental conditions to consider is temperature. The manufacturer specifies in the data sheet how the characteristics of a component vary with temperature and other environmental conditions.

Safety considerations

Some of the most common risks associated with using capacitors include electric shock hazard, venting, and catching fire. These risks vary depending on the capacitor technology and specifications of a given component. For instance, aluminum electrolytic capacitors, especially those that are designed to operate at high voltages, can cause lethal electric shocks and should be handled with extra caution. Information on the potential risks associated with a component is usually included the data sheet.

Storage conditions

For most types of capacitors, the performance characteristics are greatly dependent on how the components are stored and for how long. To ensure the properties of your component are not greatly affected, you should store them as specified by the manufacturer. Details on the recommended storage conditions and instruction on how to use a component after storing it for a period of time are usually provided in the data sheet.

Image source: tdk.com

Test information

For some capacitors, the manufacturer may provide test information to enable designers to assess if a component is suitable for a specific application or not. For instance, for film capacitors, most manufacturers provide details on various tests including robustness of leads test, dry heat testing, damp heat cyclic testing, rapid change temperature testing, cold testing, and steady state damp heat testing.

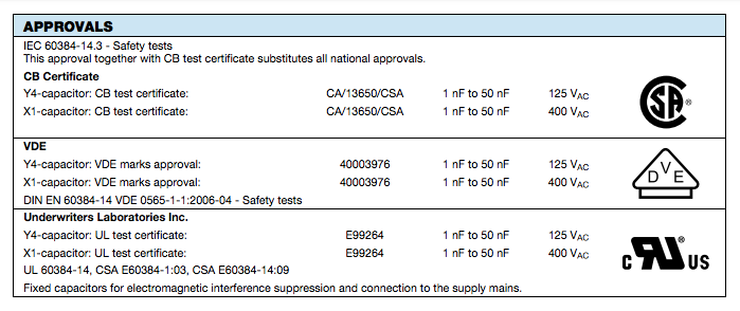

Qualification/Certification

Some applications demand capacitors that meet stringent performance and reliability requirements. This information includes test methods and helps circuit designers to know if a component complies with the specific demands of a given industry.

Image source: www.vishay.com

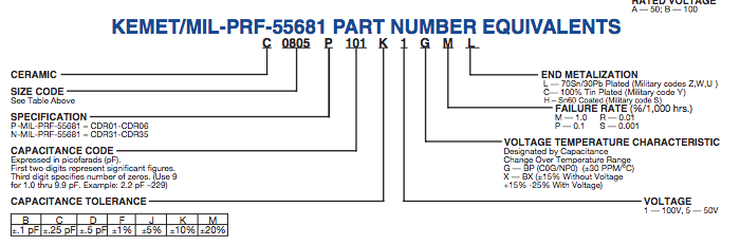

Ordering information

This section helps a circuit designer to familiarize with the numbering system used by a manufacturer. The section also provides other manufacturer specific guidelines that can help a circuit designer to order components with ease.

Image source: kemet.com

Disposal of Capacitors

Some capacitors contain toxic materials, and it is important to ensure that they are disposed in the correct way to prevent contamination. This section helps circuit designers and engineers to know the risks associated with incorrect disposal of a given capacitor technology and how to mitigate them.

Others

Other sections/subsections that are common in capacitor data sheets include the following:

- Tape and real packaging information

- Product marking

- Pad layout dimensions

- Disclaimer

Millions of high reliability capacitors are catalogued In doEEEt with the full ordering info, applicable specifications and main parameters.

Choose the right capacitor for your application just clicking in the CAPACITORS category and narrow the value of your parameter selection in the FILTERING AREA.

Or just add a bunch of them to our COMPARISON TOOL and select at a glance the properest capacitor in terms of quality, electrical parameters, and procurement

Source: Capacitor Faks blog

by: Anthony Kelly, Capacitor Faks

Featured image source: Kemet and AVX capacitor datasheet

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on How to read a capacitor data sheet