Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

- Posted by doEEEt Media Group

- On December 2, 2020

- 0

Panasonic Commercializes, with the Industry’s Largest Ripple Current

Panasonic Corporation announced today that it’s Industrial Solutions Company had commercialized new conductive polymer hybrid aluminum electrolytic capacitors, the large-current ZU series, and large-capacitance ZSU series for use in automotive ECUs (electronic control units) [1].

Mass production will start in December 2020. The new ZU series has achieved ripple current*1 of over 1.4 times as large as the conventional ZS series (ϕ10 x 12.5 mm and ϕ10 x 16.5 mm), supporting increases in circuit load current due to high-performance automotive ECUs and contributing to smaller automotive ECUs through a reduction in the number of required capacitors.

*1: As conductive polymer hybrid aluminum electrolytic capacitors of the same size as of November 10, 2020 (according to research by Panasonic)

Conductive polymer hybrid aluminum electrolytic capacitors feature low resistance and high reliability with a fusion of conductive polymer and electrolyte. They are used in a wide range of applications, from control circuits in automotive engine ECUs, BMSs (battery management systems) [2], to motor drive circuits in 48 V system ISGs (integrated starter generators) [3], electric pumps, radiator fans, and further to ADAS applications (such as cameras, sensors, and control circuits). The progress in electrification and self-driving technology has led to the higher performance of automotive ECUs, which have increased circuit load currents.

The progress has also led to the implementation of redundant design [4] aiming to improve safety and reliability, resulting in the use of an increased number of automotive ECUs by mounting two sets of circuits in the same ECU, for example. Reducing board size is necessary for smaller mounting space, requiring cutting the number and size of capacitors by increased current and capacitance. To meet these requirements, Panasonic has commercialized the ZU series conductive polymer hybrid aluminum electrolytic capacitors with the industry’s largest ripple current by using high conductivity polymer formation technology and in-capacitor low resistance technology.

Panasonic also commercializes the ZSU series conductive polymer hybrid aluminum electrolytic capacitors with the industry’s largest capacitance*2

By adopting large-capacitance anode and cathode foils, the ZSU series has achieved 1.2 to 1.8 times as large capacitance value as the conventional ZS series products. Mass production will be launched in December 2020.

*2: As conductive polymer hybrid aluminum electrolytic capacitors of the same size as of November 10, 2020 (according to research by Panasonic)

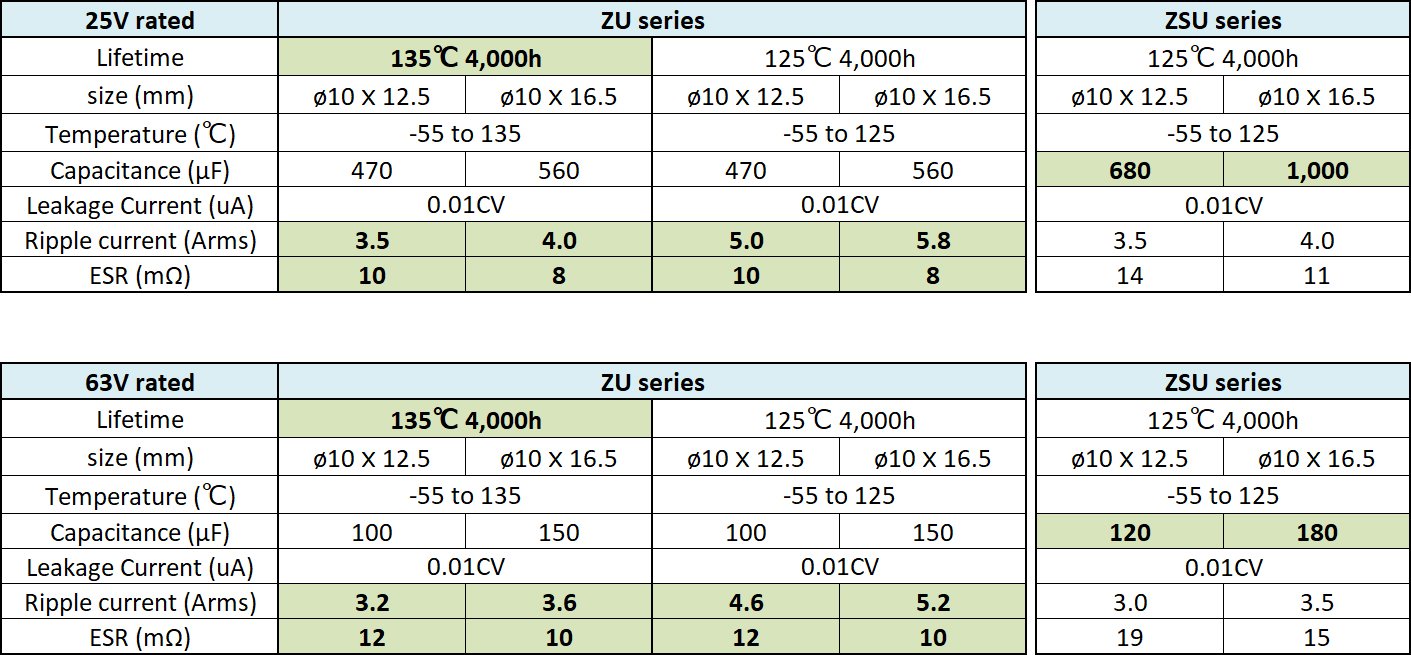

Basic specifications

Term Descriptions

[1] Automotive ECU (Electronic Control Unit)

Unit for electronically controlling systems in a vehicle.

[2] BMS (Battery Management System)

System for controlling the charge/discharge of lithium-ion batteries in xEV.

[3] 48 V system ISG (Integrated Starter Generator)

The generator that also has functioned as a starter mounted in mild hybrid vehicles.

[4] Redundant design

Progress in automatic driving requires safety designs. Redundant design enables the normal operation to continue, even if one circuit fails, by using another circuit.

Source: Panasonic

- Space-Grade components available for immediate delivery - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

0 comments on Conductive Polymer Hybrid Aluminum Electrolytic Capacitors