Comparing Film Capacitor Dielectrics

- Posted by doEEEt Media Group

- On March 9, 2021

- 0

Wilmer Companioni compares film capacitor dielectrics features and applications in his Kemet Engineering blog.

In many ways, film capacitors can be considered a near-perfect capacitor. They have lower parasitic effects than other types of capacitors and they exhibit very stable capacitance over temperature and frequency. The fact of the matter is that there is no such thing as an ideal capacitor. Aside from these technical advantages there are other things that must be taken into consideration when designing with film capacitors. Such points of consideration are size, price, and high temperature conditions. Film capacitors are generally larger than other capacitor technologies of the same voltage and capacitance. Even with those limitations, the high ripple capability, dV/dt, and self-healing characteristics of film capacitors make them an ideal choice for designers. In addition, some latest advances in film dielectric technologies and manufacturing process in capacitors have allowed film capacitors to reach new temperature and humidity heights that make them ideal for use in power and filtering applications, such as automotive, green energy, and applications where high reliability is key.

Comparing Film Capacitor Technologies

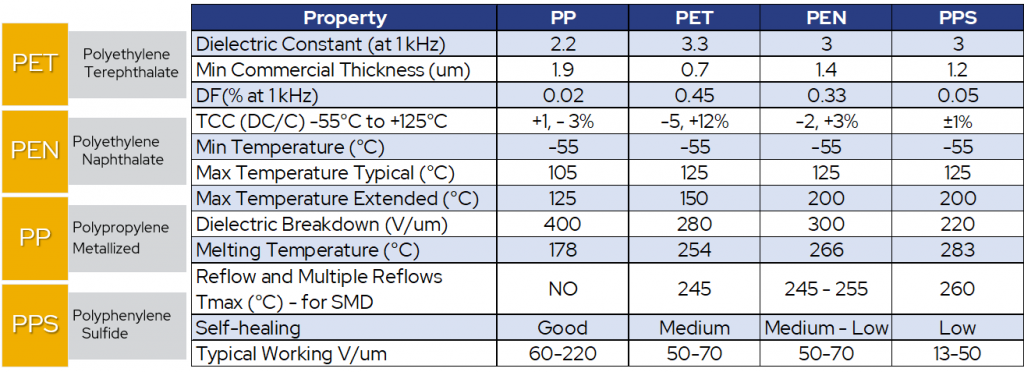

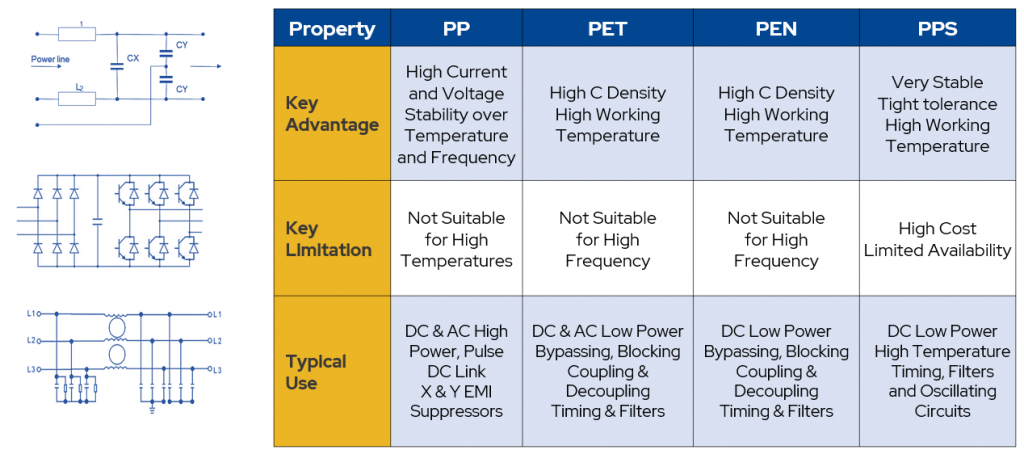

In film capacitors, it is the film itself that acts as the dielectric. Choosing the right dielectric is, as it often happens in engineering, an exercise in weighing tradeoffs. Unless you have an advanced degree in organic chemistry, being able to pronounce the full names of film capacitors can quickly become challenging. The full names of the film capacitors we will be discussing are polyethylene terephthalate (PET), polyethylene naphthalate, polyphenylene sulfide (PPS), polypropylene (PP), and polytetrafluoroethylene (PTFE). Each of these materials have their pros and cons and it is the application itself that would determine the best fit.

| wdt_ID | Material | Relative Permittivity | Max DC Voltage | Max Temperature |

|---|---|---|---|---|

| 1 | PET | 3.3 | 1,000 | 125 |

| 4 | PEN | 3.0 | 250 | 150 |

| 7 | PPS | 3.0 | 100 | 150 |

| 10 | PP | 2.2 | 2,000 | 105 |

| 13 | PTFE | 2.0 | 630 | 200 |

Here are some key advantages that may be also considered regarding the technologies.

It is polypropylene’s advantage in dissipation factor and dielectric breakdown voltage that make then ideas for power electronics applications.

PPS could be an amazing solution for solving high temperature/harsh environment solutions. The drawback is that its self-healing capability is very poor when subjected to high energy transients. Because PPS doesn’t enjoy the economies of scale as polypropylene, it is not often used as less cost-effective solution.

Looking at this table it might seem that PET is the material that has the best combination of voltage, temperature, and permittivity.

Looking at this table it might seem that PET is the material that has the best combination of voltage, temperature, and permittivity.

Stepping up the Polypropylene Game

Polypropylene has an excellent breakdown for voltage and ripple current performance but has traditionally been limited in its capability on high ambient temperature. That is until recent developments by the film manufacturers and the KEMET capacitor manufacturing process.

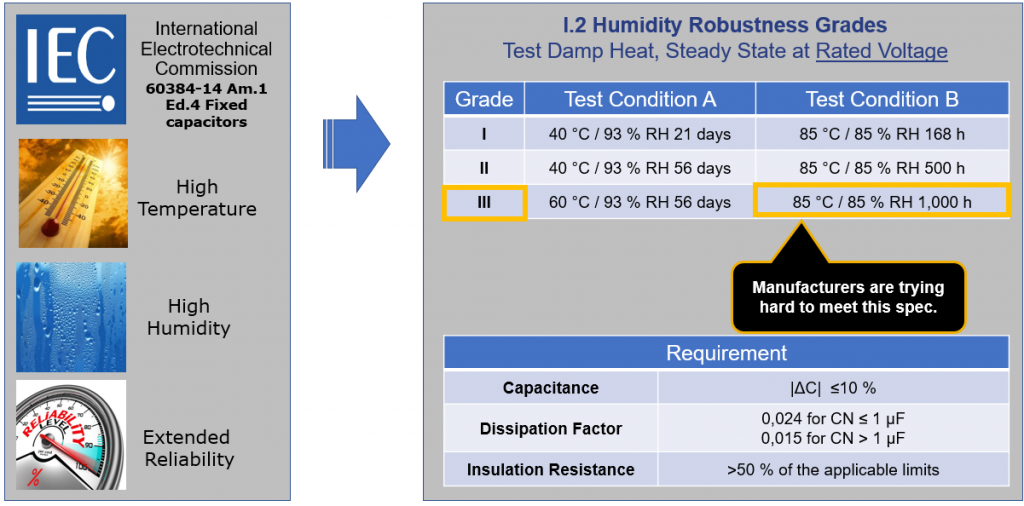

By pushing the PP dielectric temperature capability to 125°C, and special epoxy resin protection, the PP film capacitors can meet much more stringent standards such as the “Temperature Humidity Bias Accelerated Life Test” set forth by the AEC-Q200 and the latest IEC-60384-14 standard that requires components to withstand 85°C with 85% relative humidity at rated voltage for 1,000 hours. Such advances make PP film capacitors viable options for the latest automotive designs in EV/HV, green energy, industrial market, and high-reliability industries.

Below is an example of the criticality having humidity requirements and how it is now important for every capacitor manufacturer to try to reach that new specification from IEC.

- Miniature RF Connectors for high-performance testing - April 24, 2025

- Space-Grade components available for immediate delivery - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Comparing Film Capacitor Dielectrics