Inductor Core Materials and Their Losses

- Posted by Tomáš Zedníček

- On November 5, 2020

- 0

Core Materials And Their Losses

Introducing solids into a magnetic field, their behavior can be classified into three groups: diamagnetic materials / paramagnetic materials / ferromagnetic materials

Diamagnetic and paramagnetic materials have a relative permeability close to one. They are therefore only of limited suitability in the construction of inductive components. Ferromagnetic materials have a relative permeability between 10 and 100 000. In order to understand ferromagnetic core materials, the internal structure of these materials must be examined closer.

The atoms in ferromagnetic materials (termed magnetic materials as follows) have a magnetic moment. In the unmagnetized state, the magnetic moments of the atoms are aligned in all spatial directions, whereby atoms show a preferred direction within limited cells (Weiss domains). The boundaries between these Weiss domains are termed as Bloch walls.

If an external magnetic field is now applied, this attempts to orientate the magnetic moments along the magnetic field direction, whereby the crystal direction remains the preferred direction. This occurs because the Weiss domains with a magnetic moment in the direction of the field grow at the expense of neighboring domains. This is described as shifting of the Bloch walls. This is a reversible process within certain limits.

If the field strength is increased, the Bloch walls jump from one defect site to the next. This is then no longer reversible. If all domains are aligned, a further increase in the magnetic field rotates the magnetic moments from their crystal direction. Here one speaks of rotating processes.

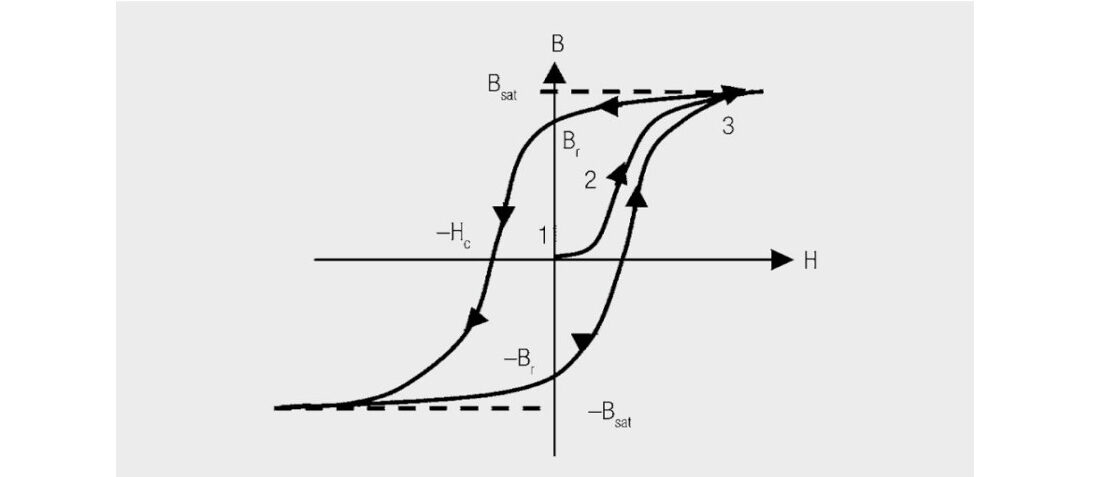

This behaviour is reflected in the hysteresis curve (also known as the B-H curve) (Figure 1.12). Reversible Bloch wall shifts predominate in the lower region of the new curve. In the middle region, where the magnetic flux density B rises almost linearly with the field strength H, the irreversible jumps of the Bloch domains (so-called Barkhausen jumps) may be identified. In the saturation range where the rise in the magnetic flux density is very much slower, the rotating processes predominate. Further growth of the Weiss domains is no longer possible.

Featured image Fig. 1.12: The B-H curve shows the magnetic flux density as a function of an imposed magnetic field

Reducing the field strength further, many of the shifted Bloch walls remain stuck at defect sites. The magnetic flux density falls along another curve. Magnetic flux is still present even when the field strength has returned to zero. This refers to remanent flux density Br. In order to reset the flux density to zero, a certain negative field strength has to be applied, the so-called coercive field strength HC. The hysteresis curve profile is dependent on the material.

According to the value of the coercive field strength, “soft magnetic” and “hard magnetic” materials are distinguished.

- soft magnetic materials: HC < 1000 A/m are mainly used in inductive components

- hard magnetic materials HC > 10000 A/m are mainly used as permanent magnets and with electromagnets

The area within the hysteresis curve corresponds to the core losses per cycle. At higher frequencies, there are also eddy current losses.

A frequently asked question concerns core material losses and the resulting power dissipation through ripple current in the storage choke. We will provide some basic information in this section.

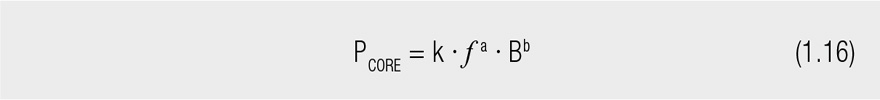

Expensive measuring techniques are required to determine core losses. These are generally based on the measurement of parameters defined for toroidal ferrites and in order to obtain relatively accurate results, phase-accurate power amplifiers and multiplying measuring instruments are required for power measurement with a low phase difference. The classical specification of core losses is given by the “Steinmetz formula” named after its inventor:

Figure: EQ-1_16

B = peak value of induction, Pcore is the average power dissipation per volume unit and f the frequency of the sinusoidal measurement voltage. For ferrites the coefficient “a” is between 1.1~1.9 and the coefficient “b” is in the range 1.6 ~ 3. An iterative approach is required for other materials in order to identify the coefficients.

However, in switching controller applications we find rectangular voltages across the storage choke. For a 50% duty cycle, the accuracy of the Steinmetz formula is already reduced, for small or large duty cycles errors of 100% can arise!

Figure: Example for the error in the Steinmetz formula with a duty cycle > 50% (f = 100 kHz; MnZn core)

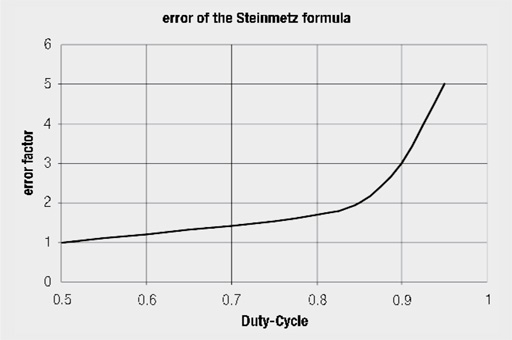

The accuracy of the Steinmetz formula is further compromised by:

- ignoring the DC pre-magnetization (→ a different B-H curve is produced!)

- ignoring the current harmonics

- ignoring the Vμsec product (higher Vμsec product ~ higher losses)

- temperature dependence of the core material (many core materials only attain their loss minimum at elevated temperatures!)

Figure: Power dissipation in the core material as a function of temperature based on the example of a NiZn power ferrite

For these reasons, all calculations with the classical Steinmetz formula must always be evaluated in the light of these facts. The safest method of assessing whether the design of a storage choke works optimally is efficiency measurement on the switching controller and the measurement of self-heating in operation (taking into account the heat coupling with hotter components such as diodes and switching transistors!).

Example: Material 1P2400

MnZn-ferrites are mainly used for transformers working in the range between 50 and 500 kHz. The material 1P2400 used in the example is characterized as follows:

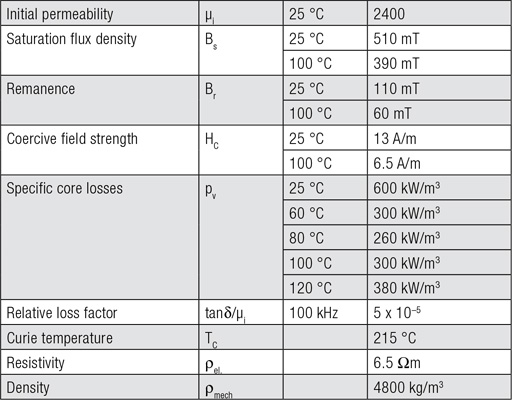

The table below provides an overview of the most important parameters of the material. The permeability μ is around 2400.

Tab. 1: Characterisation of the material 1P2400

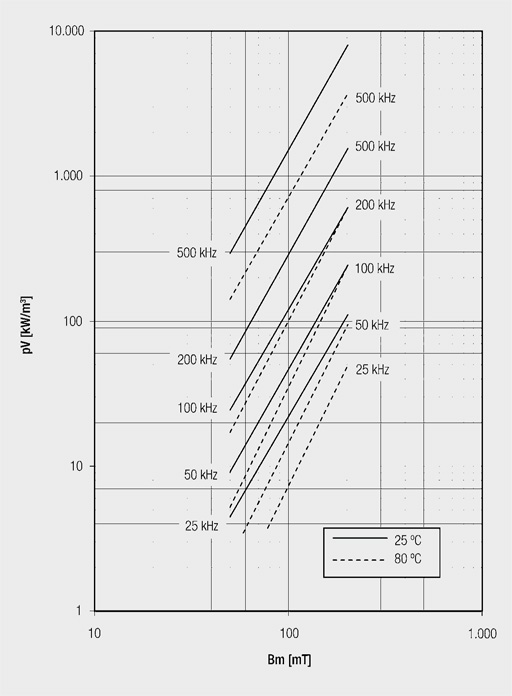

Figure Specific losses dependent on the magnetic flux density shows the specific core losses as a function of magnetic flux density at different frequencies for a sinusoidal input and temperatures of +23 °C and +80 °C. The core losses at +80 °C are lower than at +23 °C. As transformers usually work in the range between +60 °C and +100 °C due to self-heating, one can assume the +80 °C curves when calculating losses. The so-called Steinmetz coefficients may be obtained from the curves and by entering into the Steinmetz formula the losses at other frequencies and flux densities may be interpolated. F:

As the magnetic behavior of ferrites is not linear, the respective Steinmetz coefficients only apply within certain ranges. Also, switching transformers are usually not driven sinusoidally. So the calculated core loss values may deviate in reality.

Figure : Specific losses dependent on the magnetic flux density

- Why low ESR matters in capacitor design - May 24, 2021

- Voltage and Frequency Dependence on Resistors - March 6, 2021

- Permeability concept in Inductors - March 4, 2021

0 comments on Inductor Core Materials and Their Losses