Construction and Types of Wirewound Resistors

- Posted by Tomáš Zedníček

- On March 6, 2020

- 0

General Comments

As the name indicates wire-wound resistors consist of a resistive wire wound on a bobbin and supplied with a protective coating. Since the resistance wire never can serve as a termination wire because of solderability requirements, it has to be connected to the terminal leads or the like, usually by welding or brazing.

The higher the resistance value the thinner the wire that has to be used and thus the greater the risk of open circuits due to deficient weldings, damage from corrosion or from mechanical handling. Below a diameter, Φ, of 0.1 mm (4 mils) the failure rate grows rapidly.

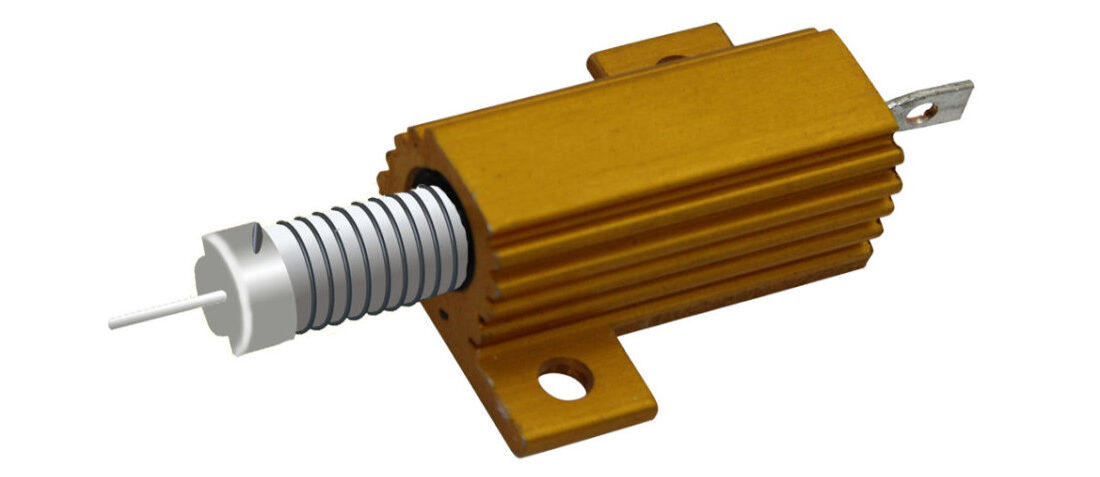

Figure 1: Construction sketch of a power resistor

Of course, the winding is inductive which might be troublesome at frequencies above 50 kHz. There exist low inductance winding styles but price and dimensions then will increase. They are used for precision wire-wound designs.

The simplest solution is by using sections of winding, with inverse winding direction from section to section, thus causing the magnetic fields to counteract each other. Less inductive will be the double-wound winding, where the wire is folded on the middle to a “double-wire” that is wound on the core. The drawback is its capacitive connection between the wire halves. This capacitive connection may be eliminated by the so-called Ayrton-Perry-winding where two wires are wound in opposite directions on the core and then connected in parallel. The drawback is the increased wire volume.

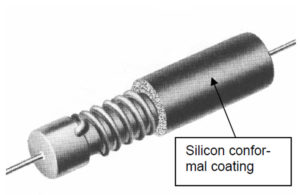

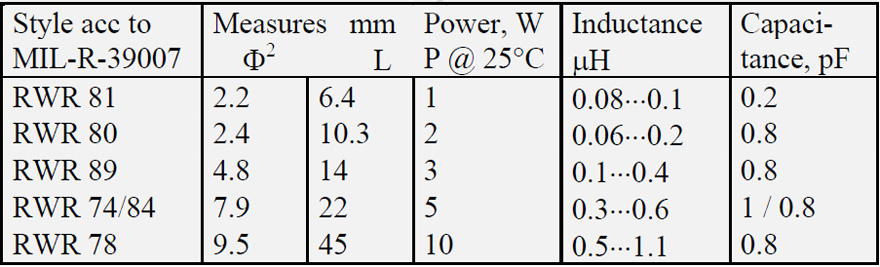

Examples of inductance in power resistors of the same design as indicated in Figure R2-1 are shown in Table R2-1 that also contain information about their capacitance. Capacitance is always developed between adjacent turns and manifests itself at higher frequencies.

Table 1. Examples of inductance and capacitance in wirewound power resistors.

[2] Φ = wire/lead diameter

Power Types

Introduction

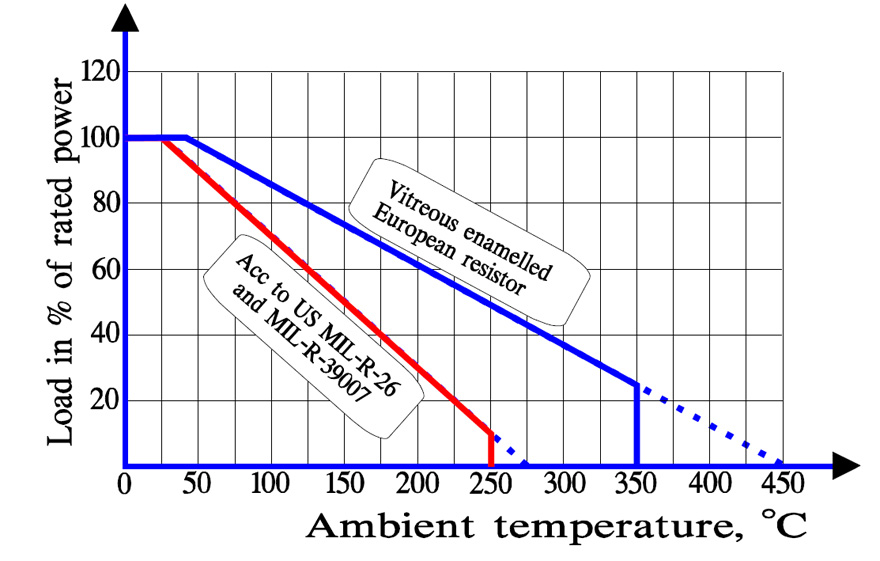

This type of resistors is, as the name indicates, designed to dissipate power. That means comparatively high operating temperatures and limited stability, which in turn influences the tolerance settings. The breakpoint of the power curve is usually situated at 25 °C. The derated part of the curve often aims at zero power at ambient temperatures like 275, 350 or even 450 °C but has a second break point at 250 or 350 °C as shown in Figure 2. Other characteristic curves don’t have the second break point. They are derated linearly to zero power and reach zero applied power at, for example, 200, 275 or even 350 °C.

Figure 2: Examples of power ratings with two break points.

The high Hot Spot temperatures of power resistors demand particular attention during mounting. Otherwise, adjacent parts may be damaged by the heat. When solder connections are used it is important to ensure that the temperature in the solder joints does not come near to the melting point of the solder.

The high operating temperatures require bobbins of a heat resistant material. Porcelain, alumina, beryllia and glass fiber cores are used. The higher the thermal conductivity, the better. The Hot Spot curve in Figure 3 then is flattened and widened to a corresponding degree. Beryllium oxide – beryllia – is the best but that material is controversial due to its high toxicity in the gaseous or powder state. It is the author’s firm and well-founded opinion that risk of poisoning is possible only when dry grinding during DPA or in the extremely rare occasion of an electric arc that may hit enameled resistors. See Caution below. Moreover, beryllium oxide resistors normally are lacquered, not enameled.

There are four main types of cover/encapsulation:

- vitreous enamel

- cement

- silicon lacquer/plastic molding

- finned aluminum housed.

Pulse loads

Wirewound power resistors can stand considerable pulse loads. The following outlines apply:

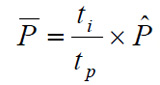

- P– should be limited to PR at periodic pulse loads. We get the connection between from:

Singular pulses must not exceed Vg2/R.

For a decreasing resistance, R, the generated power, Vg2/R, may rise beyond permissible values. We may have to set bounds for the allowable pulse load or the pulse time or both. The following calculations can be of help by determining the conditions.

By means of the thermal resistance Rth we can calculate the Hot Spot temperature Thsp from Equation as Rthx Ppulse. If we then calculate with a constant power Ppulse this power will raise the surface temperature to T¥ in Figure R2-3. When the corresponding curve passes TR we get the time tp. If the power is switched off after the time tp the temperature development certainly will get an overshoot before it turns down again. But the resistor can stand a certain over-temperature; partly the Thsp is calculated on the nominal Rth and this value is higher than the real Rth according to Figure 5. Altogether, this will compensate for reasonably hazardous temperatures.

Figure 3: Determination of the time tp when an overloaded resistor attains rated temperature.

The curve in Figure 3 is drawn by means of T∞ and τw which are supposed to be constant in these estimates. If the pulse time is longer than the one in Figure 3, for example, 2 tp, we then have to construct another curve through the coordinates (2 tp; TR) and reduce the pulse load in correspondence to the decreased T∞.

Vitreous enameled

Vitreous enamel offers excellent protection for power resistors. The quality, however, may vary. The enamel should be well adherent and free of pores and without any impurities. Quality assurance is necessary to achieve this level of quality.

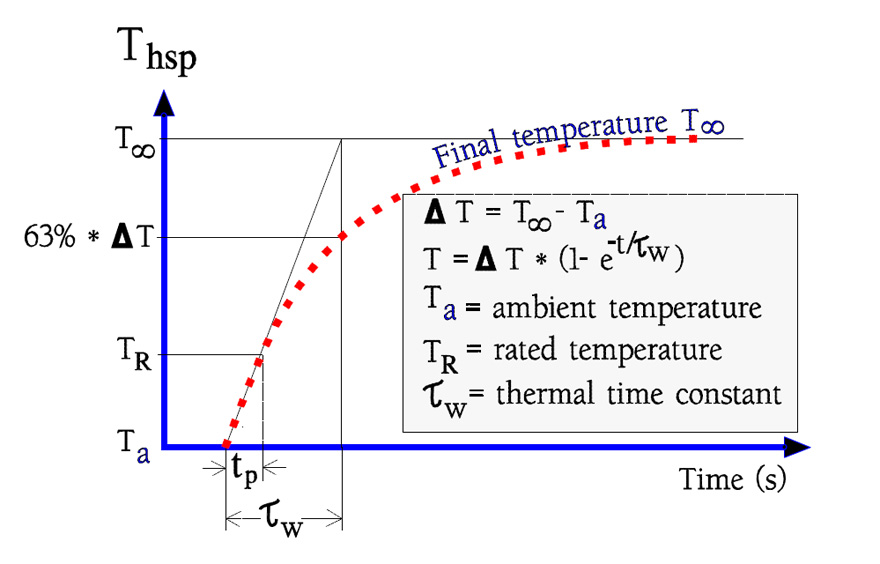

The high manufacturing temperature of approximately 800 °C brings with it certain problems. At that high temperatures, the wire stretches. Since it is wound with a moderate tensional bias it happens on geometrically large bodies that some turns stick together in a spot because of the capillary forces. Normally the phenomenon is visible only by means of X-ray. It looks like turns leaning against each other. It has not been proved that this contact leads to flash-overs between turns or any other troubles (Figure R2-4).

Figure 4: Figure R2-4. ”X-ray picture” of a winding:

a) in a normal state; b) with “stick-together” resulting from the enameling.

More troublesome is that the high manufacturing temperature makes it difficult to use solderable wire alloys of copper-nickel, both for the resistor elements and the terminal leads. The latter are tinned after the enameling process but the solderability still is deteriorated compared to that of Cu-Ni alloys.

Bigger power resistors often are manufactured with terminals of bands, lugs, shells or end caps that are soldered, squeezed or fastened with screws to the corresponding terminals on the apparatus.

Caution! If the resistor should be subjected to an unintentional strong over-load the enamel may attain its melting temperature before the wire burns off. Then the vitreous enamel will become conducting and will short-circuit the resistor. If the main circuit has low impedance and is of power type an electric arc is developed that lasts until the fuse cuts off.

Cemented

Cement is a common protection material but provides in reality only touch protection. Generally, the moisture protection is poor but there are exceptions in the market.

Lacquered / Plastic molded

Better than cement is lacquered or plastic molded resistors. Most often the lacquer is of a silicon basis. These encapsulations are not affected by the high manufacturing temperatures of the vitreous enamel and thus the resistors can be supplied with terminal leads of more solderable alloys.

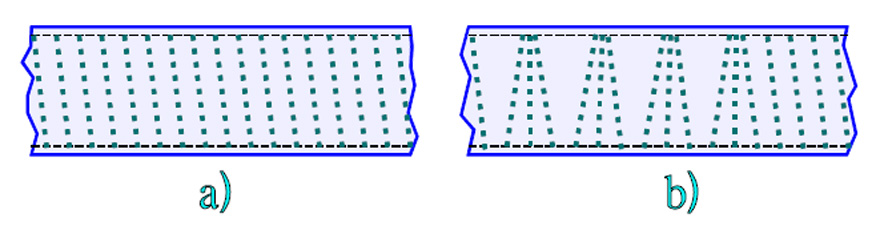

Aluminum housed, chassis mount

If we supply the resistor with a finned aluminum housing as shown in Figure 5, the Hot Spot temperature is lowered and the temperature better distributed over the length of the resistor body, which in turn permits a stronger load for a specific bobbin size.

Note! The power information of the data sheets concerning this type of resistor applies only if the resistor is mounted on the specified heat sink plates.

Figure 5: Power resistor with finned aluminum housing.

Adjustable

A quite specific type of fixed resistors are the so-called adjustable ones. See the example in Figure 6.

Figure 6: Adjustable resistor.

If possible, the use of these should be avoided. The reasons are several. The resistive wire has to be made by alloys that don’t oxidize too easily. The adjustment implies touch contact in the open window. Thus the wire will be more disposed to corrosion than that of a conventional design. The open contact window without any corrosion or touch protection doesn’t make it any better. Finally, the actual adjustment procedure is risky. It is very easy to slip with the screwdriver and damage the wire. Below a diameter, F, of 0.2 mm (8 mils) the failure rate starts increasing rapidly. Compared to other power types the adjustable have a 50……100 times greater failure rate.

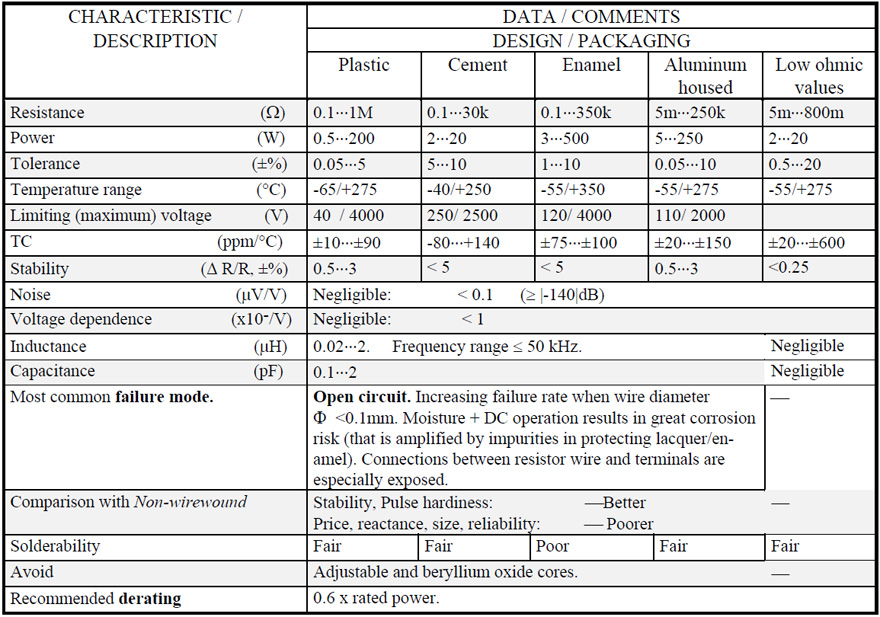

Low ohmic design

In the range from 5 to 800 mΩ so-called “low-ohmic” value resistors are offered. The resistance element consists in principle of a straight wire or band to which the terminal leads are welded. As a rule, these resistors are encapsulated.

In the low ohmic range, the TC of the terminal leads play a greater and greater part. Their own TC usually is strongly positive – for example, copper has + 3900 ppm/°C – and the lower the resistance value, the more the resistance and TC of the terminal leads to influence.

Please remember that the tolerance requirements apply only when we connect according to the manufacturer’s instructions, i.e., at a specified distance from the component body (Figure 7).

Figure 7: Measurement distance on a low ohmic value resistor.

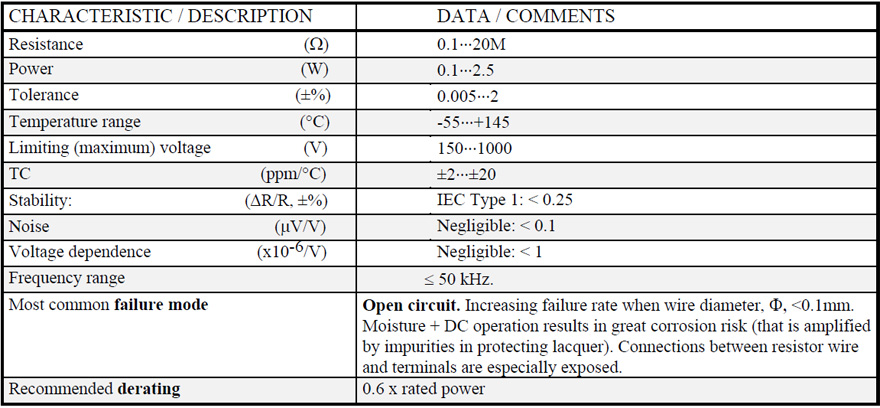

Precision Types

Precision wire-wound resistors are characterized by close tolerances, high resistance stability, moderate power ratings/Hot Spot temperatures and close TCRs. Typical values of these characteristics are shown in the following Table 3.

Introduction

More and more precision wire-wound resistors are being displaced with metal film types which have the same characteristics but considerably smaller dimensions. In older designs, however, they still exist and therefore we will deal with this component type.

In the simplest construction, the wire is wound in several layers, something like a spool of thread. Short-circuiting between turns normally is prevented by the polyamide lacquer but there have been occasions when the wire tension during winding has become too great. The polyamide “flows” away and turns have been short-circuited thus resulting in a resistance decrease – in certain cases, intermittently.

In more expensive designs the winding is divided into sections – Figure 8 – and the winding direction is veered round in order to reduce the inductance.

Figure 8: Section wound precision resistor.

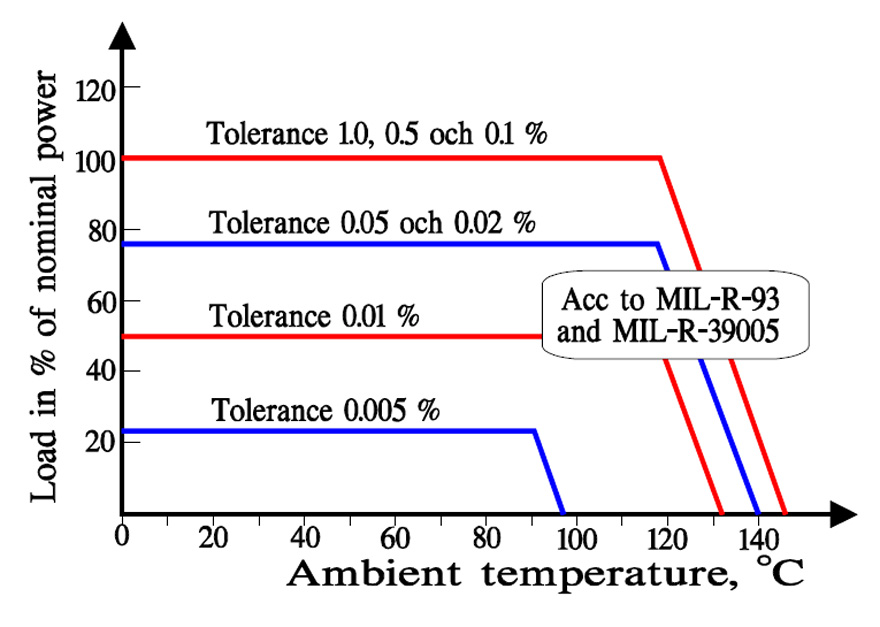

The resistors usually are encapsulated in a plastic molding. However, the liquid plastic may after-cure and the bobbin may change its dimensions. This will inevitably lead to a change in wire tension and a subsequent resistance change. The wire tension is crucial and is held as low as possible during winding. In order to prevent resistance changes during operation, such changes are released in advance by artificial aging of the whole construction at 170…200 °C. That temperature must not be exceeded in the application. The lower operating temperature, the better the stability. Thus the derating is in direct proportion to the fineness of the tolerances. Figure 9 shows examples from older editions of US military specifications on the connection between tolerance and derating.

Figure 9: Examples of connection between load and tolerances according to US MIL.

The manufactured temperature coefficient is, as the tolerance, related to the stability. By tradition, wire-wound designs have had an advantage over the metal film. It has been easier manufacturing a thoroughly checked alloy with specific TC characteristics in a wire than in a metal film. However, in recent years that difference has shrunk and in certain cases been eliminated.

Linear PTC designs

Another branch where wire previously has dominated is PTC designs. The pure metals have a greatly positive TC, between 3000 and 6000 ppm/ °C, and accordingly, this has been utilized. The TC characteristic is never com-

platelet straight but swings off, more or less. If we, on the other hand, compare with thermistors the TC curve is “straight”. Everything is relative. Since the resistivity for pure metals is low compared to traditional resistance wires the resistance range will be greatly limited on higher values.

SMDs

Resistor chips in wire-wound design are not common. There are precision designs for SMD but they actually consist of molded variants where the axial terminal leads have been bent to a so-called gull-wing shape or the like. SMD types for high power single pulse resistors also exist. A typical appearance of a molded surface mount 5W wire-wound resistor is shown in Figure 10.

Figure 10: Wirewound resistor for surface mount.

Summary Tables

At the end of every part, we will present summary tables with characteristic data collected in a clear way. The information is based on a synthesis of the more important manufacturer’s catalog data as well as on the author ’s analysis of information from present literature in the field.

Behind the headings resistance, power, tolerance and TC manufactured maximum and minimum values from the more serious suppliers are shown. Even if extremes have been excluded as far as possible, the content in the tables should not be regarded as recommended manufacturing ranges. Moreover, one manufacturer may cover the upper part of the range, another the lower part. Recommended manufacture ranges are found in the so called QPLs – qualified product lists – and they usually have a more limited extension except for one important consideration: stability. There, respective standards show maximum limits for changes and they usually are higher than the manufacturer’s catalog data that sooner show typical changes. Stability data in the tables are based on information from standards. Since the standards contain different degrees of severity we can’t get any unequivocal stability information but a range.

The general derating that is recommended is based on the author’s experience and analysis of relevant information within the subject field. One source of information ought to be mentioned: MIL-HDBK-979. More severe environments and important applications may justify a harder derating.

Table 2. WIREWOUND POWER TYPES

Table 3. WIREWOUND PRECISION TYPES

- Why low ESR matters in capacitor design - May 24, 2021

- Voltage and Frequency Dependence on Resistors - March 6, 2021

- Permeability concept in Inductors - March 4, 2021

0 comments on Construction and Types of Wirewound Resistors