Some Quality Consideration of Commercial Laser Diodes for Space Application

- Posted by Liu Hongmin

- On December 3, 2019

- 0

TOPICS

- The advantage and usage of LDs in space missions

- Quality consideration of commercial LDs

- Discussion on the quality assurance process

- Some conclusions

Advantages of LDs

- High data rate, easily to 50Mbit/s

- High coherence, directionality and monochromatic light

- High resistance to EMI

- Small size ,light weight and lower cost

- Widely used in high-speed network communication

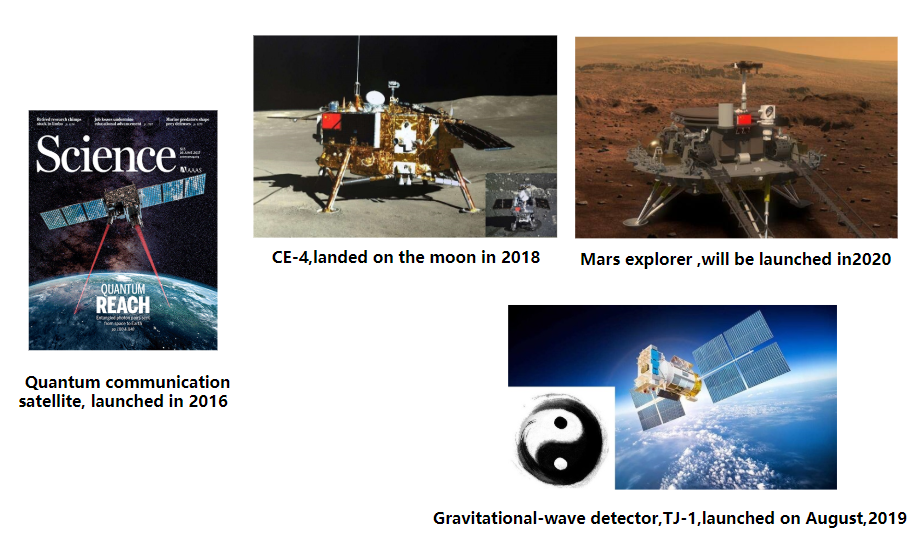

Chinese space missions with LDs application

Laser Diodes in stock

- No military or space level products.

- No consideration of mechanical vibration in launching stage, vacuum and radiation environment in space.

- Not be reliability tested and assessed of a lifetime.

- No information about the design change, manufacture process, delivery and storage for end-user.

Quality consideration of commercial LDs

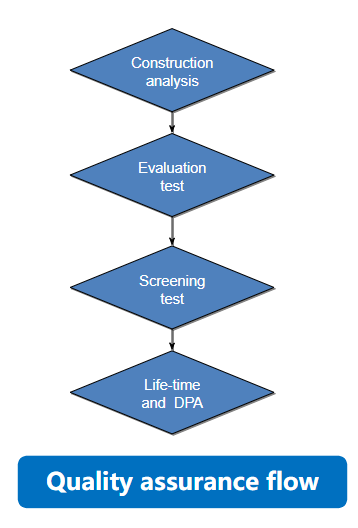

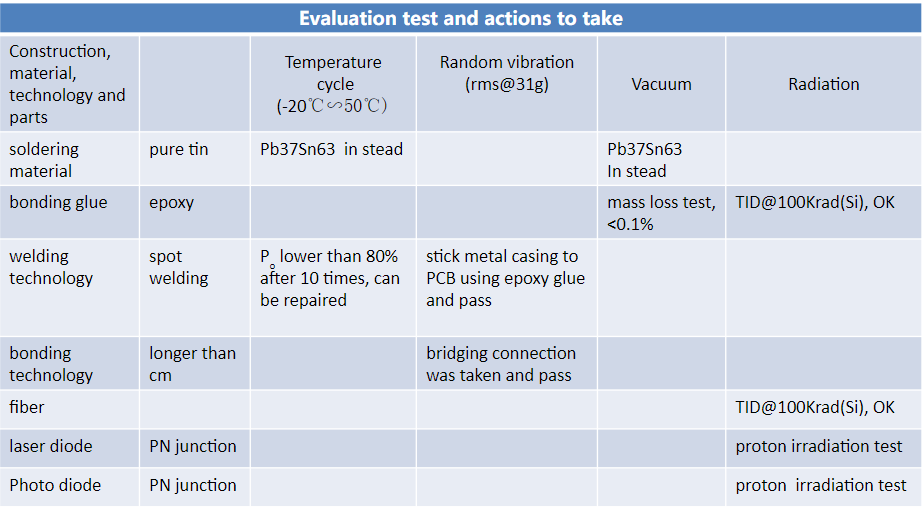

- Construction analysis

Performing construction, material, technology and component analysis to determine the items of accelerated-stress test

- Evaluation test

To estimate the ability to work normally in space and acquire reasonable screening, life-time and DPA test methods and conditions.

- Screening, life-time and DPA

To meet the requirement of quality assurance of the mission in batch.

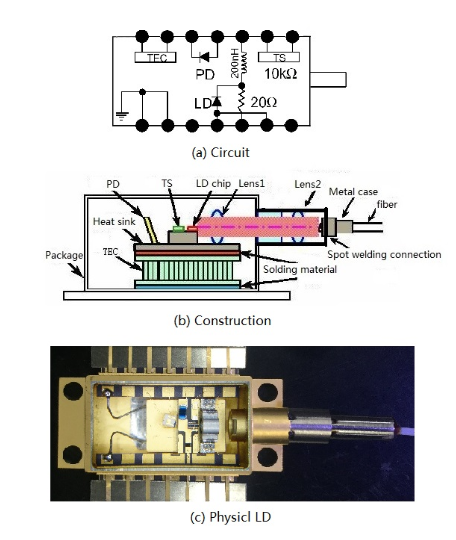

An example of construction analysis: DFB butterfly package LD with fiber-coupled

- Construction

butterfly package, sealed

- Material

package, soldering, bonding wire, bonding glue, metal casing and fiber

- Technology

Soldering, bonding, welding and sealing

- Parts

resistor, thermistor, inductor, laser diode chip, photodiode chip, TEC

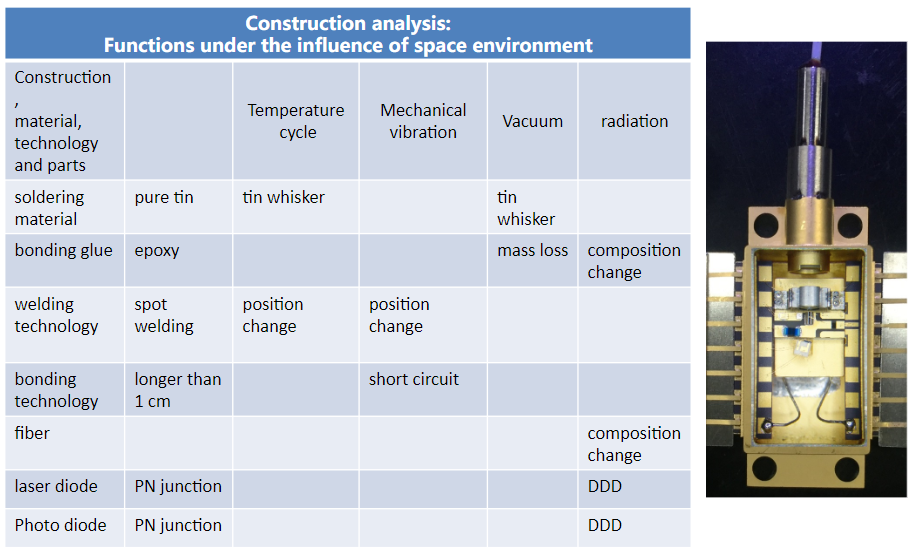

Construction Analysis

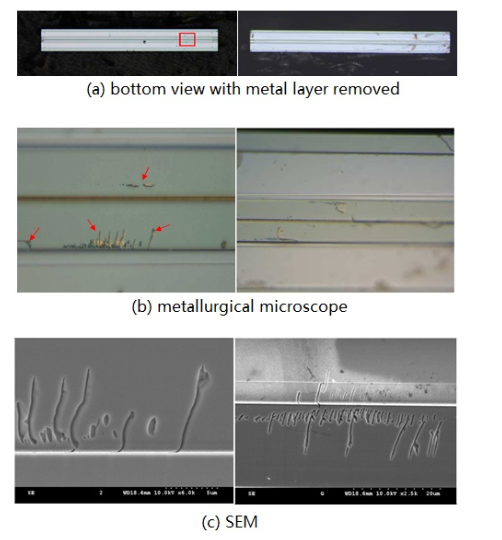

- LD chip defects

There are some strips and cracks near the active region, which will expand under the influence of working current and temperature

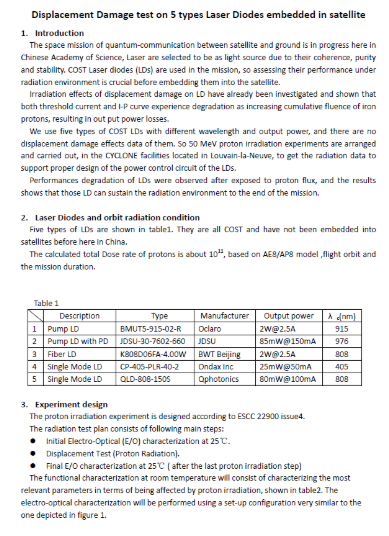

irradiation test

- More than 10 types of LDs

- 50 MeV proton irradiation, the total Dose rate of protons is about 1012, in the CYCLONE facilities located in Louvain-la-Neuve

- Cooperated with Alter, some results published in RADECS2015

Discuss on the △Po after the temperature cycle test

- For LD with fibre, the Po will drop down to less than 80% of rated Po after more than 10 cycles of TC test.

- The main reason for large △Po is because of the stress release of the spot welding connection of the metal casing, leading to the position and the direction change. This could learn from the data of PD.

- The position and the direction change of metal casing can be repaired, but not recovered.

- So, the repair was executed after every 10 cycles of TC. test, the one, which △Po / Po can not be fixed to less than 10%, was rejected but not counted into PDA.

Discuss on the conditions of burn-in and life-time test

- From construction analysis, there are some defects near the active region, which will expand under the influence of current and temperature.

- There was a failure of after 1000h and 2000h lifetime test, because of the expanding of these defects to the active area.

- The defects in nature and not be controlled during the manufacturing process for commercial LD. If the burn-in and life-time test are conducted under the rated PO,this could expand the defects with the most acceleration, leading to the rejection of the whole batch.

- For end-user, the detail information of LD chip is unknown, the conditions of burn-in and life-time test, such as the value of PO,IF,VLD and TTEC, are reasonably considered according to the working conditions in orbit.

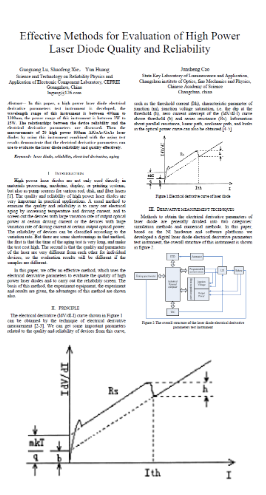

Discuss the assessment of the quality of LD

- Assessment base on LD parameters

In LD specifications, Po, ITH,IF and Po-IF curve are used as parameters to describes the performance of LD. So, usually, these parameters are tested and analyzed to assess the quality of LDs in related standers or instructions about screening and qualification.

For commercial LDs,there is higher discreteness of these parameters in a batch, so it is hard to select a good one to be assembled in the system. For example, two LDs with large different Po but with the same ∆ Po after the burn-in test, it is hard to tell which one is better in quality.

- Assessment base on PN junction parameters

It is been researched using PN junction parameters, derived from LD parameters, to evaluate the quality.

The PN junction parameters are m, h, b and P.

“For a laser diode, m represents the material quality and technology level. If m is small, it accounts for that the defects, the dislocation and the internal stress damage in the epitaxial layer are relatively small, such devices are generally reliable”.

So the problem of which is better in quality, for two LD with different Po and the same ∆ Po after the burn-in test, could be solved.

Some conclusions

- Commercial LD have been used in space very well and will be used in a future application.

- There are defects, which will grow under the influence of current and temperature, so the test conditions of screening and qualification must be considered reasonably according to the type, working environment and conditions.

- For commercial LD, the parameters of PN junction are useful to describe the quality and reliability of LD.

- Some Quality Consideration of Commercial Laser Diodes for Space Application - December 3, 2019

0 comments on Some Quality Consideration of Commercial Laser Diodes for Space Application