Small Satellites Demand Innovation in Reliability

- Posted by Harald Schone

- On November 21, 2019

- 0

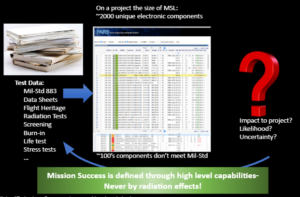

The Challenge of too Little Information

- Most COTS components are high quality

- Long term reliability for highly scaled CMOS is a concern

- Radiation data is typically unknown

- Design, process material, construction, etc. Information is useful, but vague

- Heritage rarely applies to COTS

- No traditional lot traceability, frequent undisclosed design changes

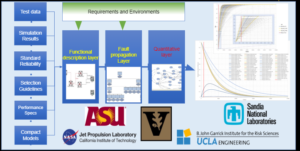

Part Level Information Flow

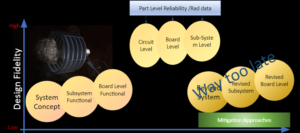

Notional Design Flow vs. Reliabilty

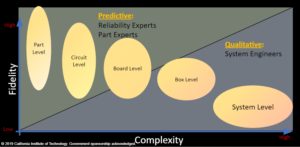

Complexity vs. Model Fidelity

Crossing Expert Domains

Lowest Level of Fidelity: COTS Radiation Guideline

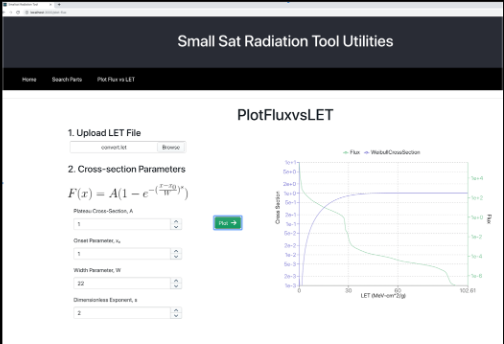

Rad Guidelines Codified in an Expert System

Lowest Level of Fidelity: COTS Reliability Guideline

COTS Reliability Codified in Expert System

Automatically retrieves Intel Fab information to predict physics of failure

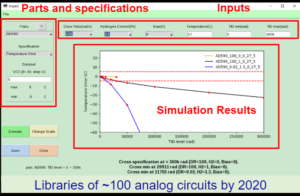

Predictive TID for Analog Devices: IMPACT

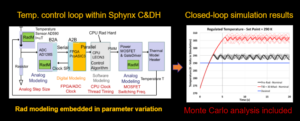

Predictive Rad Modeling at the circuit/board level

System Level Model-based Assurance

User Reports

Conclusion

The (Unexpected) Benefits of Modeling

- Modeling can be a powerful RHA tool

- Make use of vague information

- Expert knowledge can flow into model if properly weighted

- Effective way to collect information (standard format, metadata, C.C.)

- Enables information sharing

- Sharing piles of papers, lists of lessons learned or best practices is cumbersome and discourages adoption

- A guide through a design/development/Ops process

- Model fidelity needs to be adapted to stages in design

Latest posts by Harald Schone (see all)

- Small Satellites Demand Innovation in Reliability - November 21, 2019

0 comments on Small Satellites Demand Innovation in Reliability