Reviving U.S. military standards to infuse new technology and to meet the needs for new missions

- Posted by Shri Agarwal

- On December 3, 2019

- 0

- Thank you ESA and the ACCEDE organizing team for your invitation. It’s always a great pleasure to visit with you folks and exchange ideas.

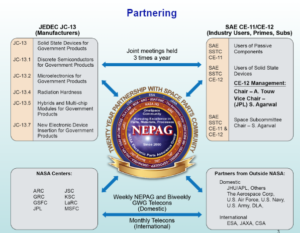

- ESA is our valued partner in NASA Electronic Parts Assurance Group (NEPAG), which is approaching its 20th anniversary.

- NEPAG is about all facets of standardization. It requires extensive communication. See next page.

Introduction

- This is the 50th anniversary of Man’s landing on the moon. A lot has happened during this period. Many notable successes kept us going. The failures gave an opportunity to make process improvements.

- Thru this all, the mission assurance organizations at NASA have supported many space missions/programs, large and small. Today, that spectrum has gotten wider, ranging from smallsats/cubesats to flagship missions such as the planned Europa mission. As always, the success of each and every mission counts.

- This presentation is about infusion of new technology into U. S. military standards, and the work underway to meet the needs of new missions.

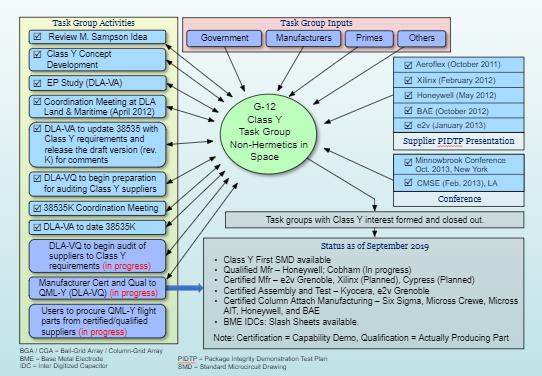

Class Y, A New Beginning for New Technology Infusion

- ClassY was discussed in detail at this year’s ESCCON.

- It represents advancements in packaging technology, increasing functional density, and increasing operating frequency. These are ceramic based single-die system-on-a-chip (SoCs) with non-hermetic flip-chip construction, in high-pin-count ceramic column grid array (CGA) packages. These products use tiny base electrode metal (BME) capacitors for signal integrity, and vented packages for thermal management. (e.g., Xilinx Virtex-4 FPGAs)

- To address the manufacturability, test, quality, and reliability issues unique to new non-traditional assembly/package technologies intended for space applications

- Introduced a new concept called Package Integrity Demonstration Test Plan (PIDTP) – provided flexibility to manufacturers.

- This initiative resulted in a major overhaul of MIL-PRF-38535, particularly with respect to requirements for flip-chip, underfill, CSAM, column grid arrays, etc. Revision K reflecting these changes was released in December 2013.

- Started JC-13.7 to address infusion of new technology

Infusion of the New Class (Y) Technology into the QML System for Space (Status given at JEDEC in Sept. 2019)

A Changing Landscape (Shipping/Handling/ESD Challenge)

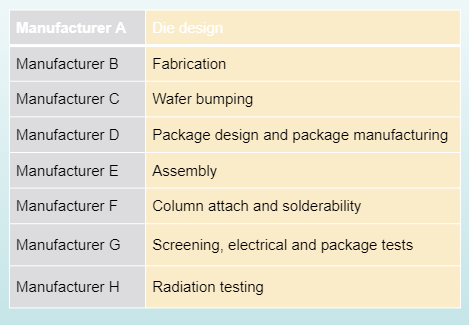

A New Trend – Supply Chain Management

Ensuring gap-free alignment for each qualified product

(All entities in the supply chain must be certified/approved)

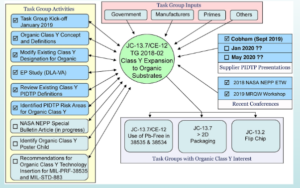

ClassY Moving Forward

- A Follow-on to Ceramic Substrate Class Y

- Interest in organic Class Y, and molded plastic parts is growing.

- The JC-13.7 created a new task group on organic substrate Class Y (September 2018).

- Related task groups started as well (next slide)

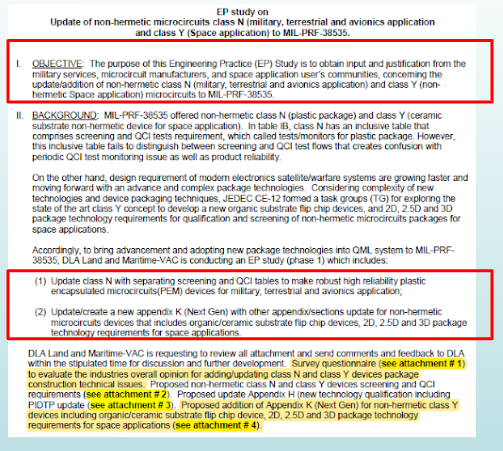

- Defense Logistics Agency (DLA) conducted an EP (Engineering Practice) study

JC-13.7/CE-12 Task Group 2018 – 02 Organic Class Y Status Slide (updated September 2019)

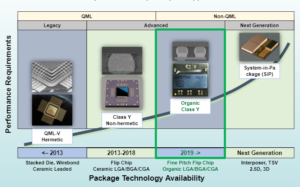

Next Generation Package Technology for Space

Development Roadmap for Space Applications

Cubesats for Deep Space Exploration

- Growing Use of NASA Cubesats

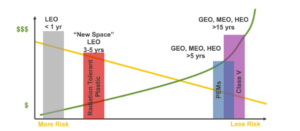

- Many new NASA missions are Cubesats and Smallsats. Major suppliers, such as Texas Instruments, Analog Devices, Cobham, and Renesas, offer a range of up to seven solutions depending on quality, reliability, radiation, and cost. (This is not to say that the demand for standard QML products are going away – the manufacturers have reported robust sales of standard microcircuits.)

Newer Applications

Newer Applications

- CubeSats

- SmallSats

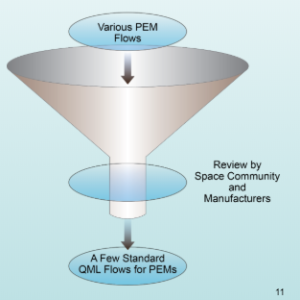

Standardizing on a few well-defined flows rather than multiple flows defined by each manufacturer or by each standards group (including Automotive and VID parts).

SAE AS6294, developed by CE-12, would be a good starting point.

JC-13.7/CE-12

DLA Engineering Practice (EP) Study

Conclusion

- New technology infusion is an on-going challenge.

- NASA supports a wide spectrum of space missions/programs ranging from smallsats/cubesats to flagship missions such as Juno and the planned Europa mission. The success of each mission is important.

- NASA is working with the space community to help infuse new technologies during the coming decade. ESD aspects should not be ignored. We encourage the world wide space community to get/stay involved in developing/updating standards.

- ACCEDE is a useful resource in these endeavors.

Short Videos on MarCO and Mars Helicopter

Here are the URLs for the videos

- Cubesats support to Insight Lander

- Mars Cube One, or MarCO was a Cubesat mission comprising two functionally identical six-unit Cubesats accompanying the Insight Mars Lander.

- Excerpts from November 27, 2018 email from the Office of JPL Director:

- We knew almost immediately that Insight had landed safely thanks to MarCO A and B.

- By successfully relaying data from another planet, this technology experiment has opened new possibilities for space exploration.

- MarCO – First Interplanetary Cubesat Mission Video URL

https://www.jpl.nasa.gov/video/details.php?id=1381

- The Mars Helicopter for Mars 2020

- Weighing at less than 4 lbs, the Mars Helicopter will be part of the Mars 2020 Rover mission. Many challenges include withstanding temperatures dipping down to -130F (-90C).

- NASA Chopper Ready for a Spin on Mars Video URL

https://www.jpl.nasa.gov/video/details.php?id=1579

http://nepp.nasa.gov

ACKNOWLEDGMENTS

The research described in this publication was carried out, in part, at the Jet Propulsion Laboratory, California Institute of Technology, under a contract with the National Aeronautics and Space Administration. Help is gratefully acknowledged from Kirk Munsell, Mohammad Mojarradi, Joon Park, and Michael Sampson. Government sponsorship acknowledged.

BACKUP MATERIAL

Space Parts World

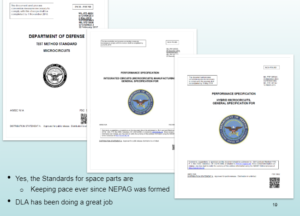

NEPAG helps to Develop/Maintain Standards for Electronic Parts

The parts users and standards organizations work with suppliers to ensure availability of standard parts for NASA, DoD, and others. For Space microcircuits, DLA, NASA/JPL (S. Agarwal*) and the U.S. Air Force / Aerospace Corp. (L. Harzstark) form the Qualifying Activity (QA).

*Also Systems, Standards and Technology Council (SSTC) CE-12 Vice-Chair.

Typical Meeting Schedule for JEDEC JC-13/CE-11/CE-12 (September 2019)

Are Standards for Space Parts Keeping Pace with Times?

Renesas (Formerly Intersil)

- Newer products use a mix of Rad Hard and commercially developed products. Renesas calls this the Radiation Tolerant (RT) Plastic flow.

- This flow is based on SAE International Aerospace Standard AS6294/1.

- Contact manufacturer for current version of this chart.

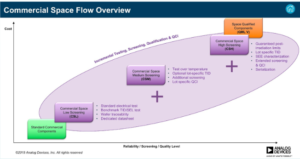

Analog Devices, Inc. (ADI)

- ADI is offering three grades of commercial space products as shown above: CSL, CSM and CSH.

- Prior to their acquisition by ADI, Linear Tech (LTC) had developed the RT (Radiation Tolerant) family of products. CSH replaces the RT family. (Linear Tech delivered PEM LTC1604 24-bit A/D converter screened to a flow developed with NASA)

- Contact manufacturer for the current version of this chart.

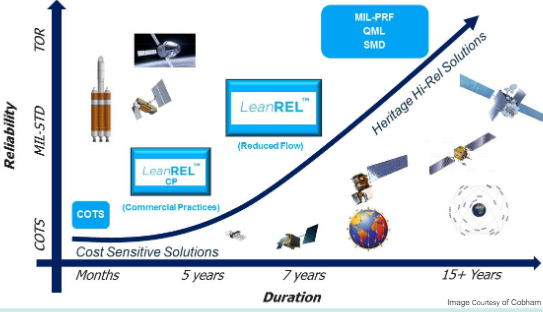

Cobham Colorado Springs

- Cobham is working to define product technologies and associated screening flows optimized and suitable for constellation space applications.

- Their LeanREL approach is aimed at meeting the mission assurance requirements for radiation performance, reliability, traceability, and cost.

- For PEMs the advantages of small footprint and mass, high performance and low cost, must be weighed against the challenges in defining acceptable flows for space.

- Contact Manufacturer for the current version of this chart.

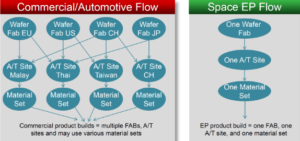

Texas Instruments (TI)

Space EP Baseline Controlled Flow

- The above chart provided by TI shows that their commercial/automotive products maybe built at multiple foundries, assembly/test facilities and may use various material sets.

- Contact manufacturer for a current version of this chart.

Evaluating Automotive Parts for Potential NASA Applications – Cont’d

AEC Q specifications are Qualification Requirements Only, Focused on:

- A One-Time INITIAL QUALIFICATION of a Device Family

- “Device Family” is Common Materials, Processes, Designs, Manufacturing Location, etc.

- “Generic Data” may be used provided relevance of data can be demonstrated

- Requirements for REQUALIFICATION

- Provides recommendations as needed

- Requirements for process change notification (PCN) to automotive customers

- THEY DO NOT PROHIBIT PURE TIN

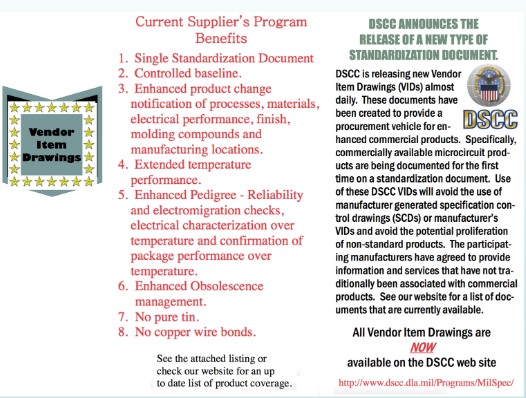

DLA’s VID (Vendor Item Drawing) Program

- Analog and digital functions offered.

- Contact DLA for updates.

Electrostatic Discharge

- NASA EEE Parts Bulletin (June 2018 – September 2018)

0 comments on Reviving U.S. military standards to infuse new technology and to meet the needs for new missions