Radiation Assurance on COTS

- Posted by Philippe Calvel

- On December 3, 2019

- 0

RADCOTS 2020 vs EAQMCS 2019

Workshop dedicated to the use of COTS (Component Off The Shelf) regarding Space Radiation Hardness Assurance.

“Emerging Assurance Qualification Methods for Commercial Systems Modeling and Experiments”

October 28th – 29th, 2019

RADECS workshop organized by the NASA Jet Propulsion Laboratory (JPL), California Institute of Technology, Pasadena California.

Organizers : Philippe ADELL & Harald SCHONE

RADCOTS 2020 vs RADECS 2020

RADCOTS 2020 – WORKSHOP

Sept. 14th, 2020 : RADCOTS 2020 Workshop

contact : radcots@radecs2020.org

> RADCOTS 2020 is included into RADECS 2020 registration fee

- Possibility to register only for RADCOTS 2020

- RADCOTS 2020 is linked with ALTER/ESA COTS Wokshop

- Therefore : Special rate for ACCEDE attendees

contact : accede@altertechnology.com

RADCOTS 2020 COMMITTEE

RADCOTS 2020 COMMITTEE

First RADCOTS organized by TRAD/CNES / USTL for RADECS in 1996

1 : Robert ECOFFET

1 : Robert ECOFFET

2 : Françoise BEZERRA

3 : Ronan MAREC

4 : Michel LABRUNEE

5 : Christian POIVEY

6 : Philippe CALVEL

7 : Christian CHATRY

8 : Allan JOHNSTON

9 : Ron PEASE

10 : Ken LA BEL

11 : Bill HEIDERGHOT

12 : Steve Mc Clure

First RADCOTS organized, in 1996, in view of :

- IRIDIUM

- GLOBALSTAR

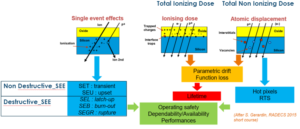

1 – COTS DEFINITION vs RADIATION EFFECTS

Main Space Radiation Effects of concern :

- We consider COTS only as electronic devices

-

- COTS equipment is an other issue to address ……

- Radiation behavior vs technologies.

- The quality level have NO impact on the radiation behaviour .

-

- COTS may be very hard or very Soft : have to be checked

- The main concern, in using COTS, is the lack of information regarding the traceability ….. for some of them

- Space qualified : radiation data may be available, not always

-

- Using COTS is of great interest for any application :

-

- To design “DREAM” products (high electrical performance)

-

- To be in advance in front of world wide competitors

-

- To significantly reduce the cost of parts

- Just replacing, pin to pin, Class S parts by COTS is not really of interest

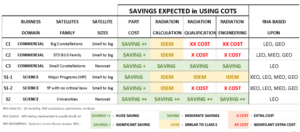

2 – BUISNESS DOMAIN OF INTEREST TO USE COTS

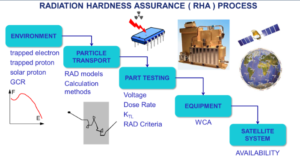

Main impact is :

- No way to have an ‘universal’ Radiation Hardness Assurance” document for all domains

- We are not talking about the same problem

- Specific RHA have to be written per domain : 6 RHA

RADCOTS 2020 will show example of RHA for each domain, based on flight lesson learnt and/or design phase

The main impact on radiation qualification testing, engineering, analysis will be analyzed. Constraint to respect will be identified :

- space radiation environment specification,

- Radiation Design Margin Policy,

- RADLAT Criteria ( if any )

- System Dependability spec & System Reliability Spec,

“ A New Way to Work for New Space “ rather than“An Old Way to work for New Space”

3 – CRITICAL POINTS FOR COTS vs RADIATION

For each application domain (c1, c2, c3, s1 & s2), which level of traceability is required for TID & TNID ?

- If Mask# & Diffusion Lot (DF) are known, then ok

- If Mask# & DF is unknown :

- Try to find the information via CPPA, or others ?

- Implement a statistical approach, based on one Procurement Lot and reliability spec ?

- Open some parts to identify the Mask# ?

- Use as Is ?

For each application domain (c1, c2, c3, s1 & s2), which level of traceability is required for ND_SEE & D_SEE ?

- If Technology & Mask# are known, then ok

- If Technology & Mask# are unknown :

- Try to find the information via CPPA, or others ?

- Implement a statistical approach, based on one Procurement Lot and reliability spec ?

- Open some parts to identify the Technology & Mask# ?

- Use as Is ?

For each application domain (c1, c2, c3, s1 & s2), analyze :

Procurement strategy :

- Directly from the manufacturer ?

- distributor ?

One procurement for the whole constellation need ?

In case of no traceability information are available,

- which minimum of construction analysis to perform ?

- Layout ? die marking ?

- TEST METHODS AND STRATEGY FOR THE USE OF COTS

For each application domain (c1, c2, c3, s1 & s2), analyze :

- Increase the sample size, directly linked to reliability spec ?

- Pass/Fail criteria for DES & NDSE directly linked to the environment, Dependability & Availability specs ?

- Testing at part level ?, board level ?, equipment Level ?

- Proton, ions, laser, … ?

- Search for all possible phenomena : SFI, Stuck Bit, MBU …. ?

- Complex parts : part validation only in the application ?

- How to prepare the DUT provided in plastic package, BGA, … ?

5 – RHA FOR THE USE OF COTS

For each application domain, how to specify the environment ? :

- Use the worst and theoretical radiation models with high uncertainty margin ?

- Use “pragmatic” models based on lesson learnt flight data over the last decades ?

- Don’t specify anything ?

For each application domain, how to calculate TID & TNID ? :

- Perform accurate 3D radiation models and perform 3D Ray Tracing calculations an 3D Monte Carlo on critical parts ?

- Determine, at satellite level, a worst case TIDL level, that all parts from any equipment, have to withstand ?

- Don’t calculate anything ?

To perform TID qualification of purchase lot ?

- large sample size n

- One-Side Tolerance Limit : KTL

- Ppost-rad = <p>+/- KTL* s with KTL = f ( n ; Q ; CL )

- with Q = tbd & CL =tbd / N =30? 40? 50? …. tbd

- To be determined in agreement with SDF at system level

To validate in its application ?

To validate with the data sheet ?

Don’t do anything ?

To perform Non Destructive_SEE qualification

- Qualification of the part in its application ? (criticity & effect)

- Accurate Testing for accurate risk assessment ? (rate)

-

- Accelerators ( ion, proton)

-

- Alternative source ( laser, ….)

- To get a maximum outage rate from the system, for validation ?

- To consider a “worst case” ND_SEE rate to apply at any part ?

- Don’t do anything ?

To perform Destructive_SEE qualification

- Simplify the requirement in term of maximum λ rate, from the system, then translate into LETcritical from environment spec ?

-

- Simplify the heavy ion qualification : pass/fail

- Accept proton induced D_SEE ?

- Integrate detection/circumvention circuitry “a priori”

-

- validation under beam

- Don’t do anything

RADCOTS 2020 will describe RHA for each domain

1 – COTS DEFINITION vs RADIATION EFFECTS

RADCOTS 2020 will present views of :

- Agencies, Prime Contractors

- Equipment manufacturers

- Components suppliers , Central Parts Procurement Agencies

- Universities

Round table discussion will be organized in // sessions

Wrapu-up & Recommandations

RADCOTS 2020 – CONCLUSION

RADECS ASSOCIATION

RADECS 2020 COMMITTEE

RADCOTS 2020 Committee

is waiting for you, in Vannes,

to attend RADCOTS 2020

&

September 14th, 2020

Vannes – Morbihan Brittany – France

www.radecs2020.org/radcots

RADCOTS 2020

RADECS 2020 – CONCLUSION

- Radiation Assurance on COTS - December 3, 2019

0 comments on Radiation Assurance on COTS