Introduction of DLR EEE-Working Group. “The usage of automotive components in space applications

- Posted by Burak Gökgöz

- On December 3, 2019

- 0

Overview

- German Aerospace Center (DLR)

- DLR EEE-Components Division

- Objectives

- National annual EEE-Components Conference

- New Space

Working Group :“Usage of Automotive Components in Space Application”

German Aerospace Center (DLR)

DLR has approximately 8700 employees at 27 locations in Germany

DLR has approximately 8700 employees at 27 locations in Germany

- Research and Technology

- Space Administration

- Project Management Agencies

Research Areas:

Aeronautics, Space Research and Technology, Transport, Energy, Defence and Security, Space Administration, Project Management Agency

Research and Technology

The German Aerospace Center (DLR) provides ground-breaking services through the combination of research in aeronautics, space, energy and transport, as well as the cross-sectoral fields of security and digitalization. With its scientific and technical expertise, DLR strengthens Germany‘s position as a scientific and economic location.

Space Administration

DLR has been assigned the task of the German national space agency. Acting on behalf of the German Federal Government, the DLR Space Administration designs the German space programme and implements it in cooperation with national and international partners.

Project Management Agencies

The DLR portfolio is complemented by the DLR Project Management Agency and the Project Management Agency for Aeronautics Research and Technology. These agencies support their clients in planning, implementing and communicating funding programmes and other measures in research, education and innovation.

DLR EEE-Components Division

Objectives

DLR EEE-Components Division

National annual EEE-Components Conference

Which serves as an exchange platform for:

- Demand and availability of EEE-components

- Information of national funding opportunities

- Status of ongoing national technology and qualification programs

- New technologies for future applications

- Information of planned activities

- Updates on ESCC and ECSS with support of ESA

Special Editions: (each 2-3 years to invite one nation)

Extension with participation of other nations and national space agencies

DLR EEE-Components Division

National annual EEE-Components Conference

- 23th & 24th of May 2019 in Bonn @ DLR

- Over 130 participants

- 25 oral presentations

- Industrial Exhibition

- Panel discussion

Participants from 50 organization (few examples)

DLR EEE-Components Division

New Space, Motivation

As space industry is facing a process of renewal, the possible usage of non-space parts in space missions to reduce overall costs, improve availability, reduce lead time and increase flexibility (functionality, new technologies) is getting more and more of crucial importance.

Way forward: Usage of automotive EEE components in space applications

Why focus on Automotive parts?

-

- Strategy in automotive industry (e.g. Standardization, Designed for Manufacturing, Product Roadmaps, Life-Cycle Management, established processes etc. )

- More recent technologies and features

- Significantly lower costs, shorter lead times, better availability

- Guaranteed reliability and temperature ranges

- Many German Automotive parts manufacturers have also Space Productions

DLR EEE-Components Division

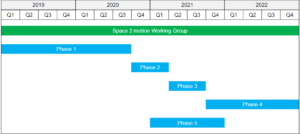

Introduction, Space2Motion Working Groups

DLR initiative: “Space sector meets automotive industry”

Exchange platform for automotive and space sector not only for EEE-Components

Working Group : Usage of Automotive Components in Space Applications

- Kick-off Meeting in January 2019

- Finalization of Terms of Reference in July 2019

Scope (finalised)

-

- Phase 1 – Identification

- Phase 2 – Analysis

- Phase 3 – Concept Development

- Phase 4 – Concept Verification

- Phase 5 – Development of an exchange platform/ Data Base

Participants (finalisation ongoing) for each Phase

-

- EEE-Components manufacturers (Automotive and Space)

- EEE-Components users

- Automotive OEMs

New Space – Working Group

“Usage of Automotive Components in Space Application”

Phase 1 – Identification

Target: Understand the past and define the most critical parts (user needs)

- Which parts are needed:

- Consolidate future need of German users, focus on critical space parts (e.g. long lead times, high costs, quality issues, new functions/technologies)

- Lessons Learned:

-

- Experiences from previous programs using non-space grade parts (e.g. TET-1)

- Studies related the usage or evaluation and qualification of non-space grade parts

- Participants: (incomplete list)

- More than 20 companies/institution/university are already part of the WG

Phase 2 – Analysis

Target: Understand the Delta and identify the challenges

- Market Analysis: Overview of automotive parts from Germany which are potential replacements for identified critical space parts

- Perform a GAP-Analysis:

Differences between ESCC/MIL qualified parts and AEC-Q parts- Analyze based on documentation, specifications

- Consider

- Class 1,2,3 per ECSS-Q-ST-60

- Evaluation and qualification philosophies

- Mission profiles of automotive parts

-

- Data collection for selected automotive parts qualification

- Identify the challenges resulting from use of automotive parts (some examples)

-

- Pure tin – mitigate whisker growth

- Risk assessment – Assess: reliability, failure mechanisms, drift calculations

- Traceability, “lot” definition, radiation: (non-)hardness

- High minimum order quantities, high non-recurring costs , smart/lean procurement process, storage and sales strategy

- Participants: (incomplete list)

- Subgroup active parts: Fraunhofer Institute, RoodMicrotec, BERNS Engineers, Hostmi, Infineon

- Subgroup passive parts: Isabellenhütte, Vishay Beyschlag, RoodMicrotec, Hostmi, BERNS Engineers

Phase 3 – Concept Development

Target: Develop a concept and verification methods to demonstrate suitability of AEC-Q parts in space applications

- Develop a concept per part type/ technology which considers different programe levels to reduces the necessary testing (Initial/evaluation, lot acceptance) cost to a minimum

- Classification of mission profiles (parameters, requirements, …)

- Define approach to way forward for identified challenges

- Test Concept Option 1: Systematic on ground testing

- Develop concept – which tests have to be performed

- Optimize concept – how to save resources, e.g. board level tests?

-

- Test Concept Option 2: On-Orbit Verification

- Develop concept

- Use of small satellites & Cube-Sats, maybe Sample return mission (?)

- Data transfer during mission time, „real-time“ analysis

- Extrapolation of data, assessment of perimeter and risk

- Develop concept

What kind of data could be gained?

To which extent is extrapolation possible?

Which operational conditions/missions can be covered?

- Usage:

-

- Detection early failures

- Launch conditions provide information about resistance to shock and vibration

- Radiation related data on DD and TID or maybe on SEE?

- Participants: (incomplete list)

-

- Subgroup active parts: Fraunhofer Institute, RoodMicrotec, BERNS Engineers, Hostmi, DLR Research and Technology, German Orbital Systems

- Subgroup passive parts: Isabellenhütte, Vishay Beyschlag, RoodMicrotec, Hostmi, BERNS Engineers, Fraunhofer Institute, DLR Research and Technology, German Orbital Systems

Phase 4 – Verification

Target: Implementation of the developed concept and testing

- Concept Option 1: Perform defined tests in lab, assess results

- Concept Option 2: OOV-mission slot, manufacturing of test boards, analysis of transferred real-time data, data evaluation

- Comparison of test data gained by the two options, assess validity of Option 2 data, define and optimize concept for future investigations

- Participants: (incomplete list)

-

- Subgroup active parts: Fraunhofer Institute, RoodMicrotec, Hostmi, DLR Research and Technology, German Orbital Systems, University Würzburg

- Subgroup passive parts: RoodMicrotec, Hostmi, Fraunhofer Institute, DLR Research and Technology, German Orbital Systems

Phase 5 – Development of an exchange platform/ Data Base

Target: To support German industry and institution

- Developing concept and programming

- Test results, documentation and all other component related information

- Participants: (incomplete list): Cheyenne-IT consulting, German Orbital Systems, RoodMicrotec, Hostmi, Fraunhofer Institute, Vishay Beyschlag

New Space – Working Group “Usage of Automotive Components in Space Application” Preliminary Schedule

0 comments on Introduction of DLR EEE-Working Group. “The usage of automotive components in space applications