COTS quartz crystal units – up-screening for space applications

- Posted by Bernd Neubig

- On December 3, 2019

- 0

Content

- Introduction AXTAL – Advanced Crystal Products

- Requirements for Quartz Crystals in Space

- Quartz Crystals compliant to ECSS3501

-

-

- Scope of ESCC3501

- Tests

- ESCC3501 Qualified Quartz Crystals and Manufacturers

- ESCC3501 Crystals from Non-ESA Qualified Manufacturers

- Sourcing Options

-

- Up-Screening of Precision Crystals

- COTS Quartz Crystal Units

- Up-Screening of COTS Crystals (Space-COTS Crystals, SCC)

- AXTAL GmbH&Co.KG

-

- Wholly privately owned company, founded in November 2003 by Bernd and Brigitte Neubig

-

- Bernd Neubig: More than 40 years technical experience in the Quartz Industry

-

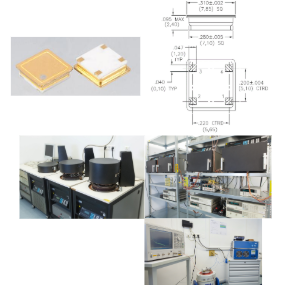

- Development, Prototyping, Testing, and Manufacturing of Frequency Control Products, namely High Performance Crystal and SAW Oscillators and Ultra Low Noise Frequency Control Modules

-

- Design & Manufacturing of Oscillators for Space since 2011.

-

- Listed on ESA EPPL since 2014 (OCXO AXIOM6060 series)

- Main markets:

-

- Space and Aerospace

-

- Navigation, Surveillance

-

- Satellite Communication

-

- Military (Ground, Mobile, Marine, Aerospace)

-

- High Precision RF Test Equipment

- Facility location: Mosbach/Baden in South West Germany

-

- Complete manufacturing line, extensive test equipment, Quality Management, R&D

-

- Quartz crystals sourced from selected manufacturers, ITAR free

Requirements for Crystals in Space

- … Strongly depending on the application

-

-

- Mission: LEO, MEO, GEO, Interplanetary, Deep Space

- Reliability Level: Cubesats, Scientific, New Space, Navigation, Telecom

- Mission Time

-

- … Strongly depending on the needed technical parameters

-

- Frequency Accuracy

- Frequency Stability over Time (Aging)

- Frequency Stability vs. Environmental Conditions

- Mechanical (Shock, Vibration)

- Radiation (TID, SEE)

- Spectral Purity, Noise

- Extremes for Accuracy and Stability

- Precision Crystals

- Frequency stability in the ppb-range (10-9) or better

- Frequently combined with demanding spectral purity and Low Noise

- Clock Crystals

- Precision Crystals

-

-

- If not time-critical: stability typically ±50 ppm … ± 100 ppm or more

- If connected with „coarse“ timing: n·1 ppm

1 ppm = 31.5 sec /year

-

-

- And many applications in between …

- Stability requirements drive Cost (Price) and Availability (Lead time)

Requirements for Quartz Material

- Radiation effects:

-

-

- Spontaneous small frequency changes

un-swept „conventional“ quartz material: 10-11/rad, swept quartz ca. 10-12 …10-14/rad - Slight reduction of Q-factor = slight increase of resonance resistance (low %)

- Spontaneous small frequency changes

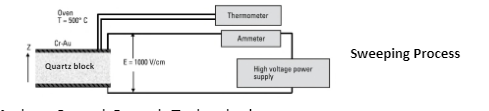

- Traditional approach (Precision Crystals): Swept Quartz material

-

-

- Modern Crystal Growth Technologies

- Ultra-low etch-channel density (ECD), and low inclusions

- Performance close to Swept Quartz possible

- Significantly lower material cost, shorter lead time

- Majority of applications (µP clocks etc.) does not need the highest level of frequency stability -> non-swept quartz

- Modern Crystal Growth Technologies

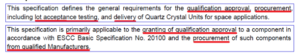

Quartz crystal units in ESCC3501

- Scope

-

- Procedures for the ESA qualification of quartz crystal units

- Procedures for qualification of crystal manufacturers

- Basis for the procurement and delivery of crystals from ESA-qualified manufacturers

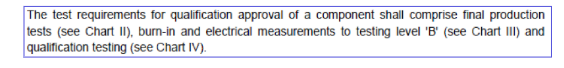

- Qualification approval of quartz crystals

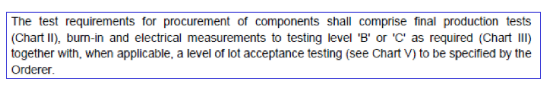

- Procurment of quartz crystals

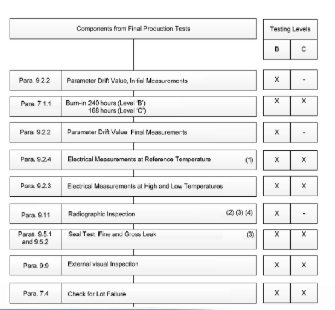

Final Production Test (Chart II)

Burn-In & Electrical Measurement (Chart III)

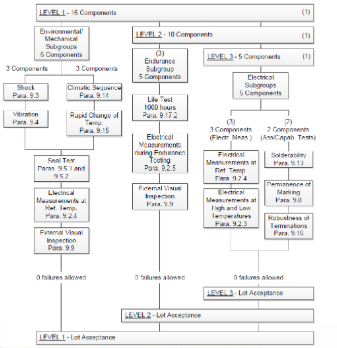

Lot Acceptance Test (Chart V) – optional

- ESCC3501 Qualified quartz crystals and manufacturers

-

- Detail Specifications ESCC3501/xxx

- /001 to /012 obsolete, active …/013, /018, /019, /020, and Blank Detail Specification

- Package styles

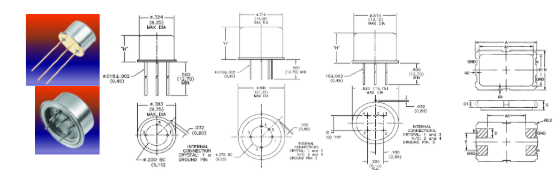

- THD: HC-35/U, HC-37/U, HC-40/U, (HC-27/U), SMD: 7 x 5 mm²/4-Pad

- Detail Specifications ESCC3501/xxx

-

- Only one qualified Manufacturer in Europe

- Qualified for two package styles (HC-35/U, HC-37/U) only

- Only one qualified Manufacturer in Europe

- Pros

-

-

- User knows what he is going to get

- Proven quality from proven manufacturer

- Profound technical specification system

-

- Cons

-

- Very limited number of package styles (no modern SMD packages)

- Expensive

- Long lead time

- Insufficient flexibility for customer/application specific products

- Not appropriate for Space COTS requirements

- …What percentage of crystals in space are really ESCC3501 parts?

Alternative 1: ESCC3501 components from AXTAL

- ESCC3501 compliant crystals from non-ESA-qualified manufacturer

-

- Supplier should have heritage with products used space

- No potentail or real risk with export / import regulations (ITAR or EAR)

- AXTAL:

- Long lsting close cooperation with CROVEN CRYSTALS in Canada

- CROVEN supplies the crystals used in the EPPL listed AXTAL OCXO AXIOM6060

- AXTAL is European agent for CROVEN high precision crystals since 2017

- CROVEN CRYSTALS:

- Founded 1954, since 2006 wholly owned by Wenzel Associates

- Leader in the design of precision qaurtz crystals

- Long Space heritage (Mars -Observer, -Pathfinder, -Climate Orbiter, -Polar Lander…)

- Canada is ESA member country

- No ITAR issues

- Audited and Pre-cap inspections yb AXTAL since 2017

- Procurement Options

-

- Shipment through AXTAL with CROVEN document package

- Optionally with LAT

- Document package content TBD

- Optional: Precap Inspection to ESCC2043501 or Factory Audit

- By customer QM, accompanied by AXTAL QM expert

- By AXTAL QM expert

- Optional: Additional Tests, Burn-In or LAT performed by AXTAL

- In accordance with ESCC3501 or Customer Specific

- Radiographic Inspection IAW ESCC2093501 (external lab)

- Total Dose Test IAW ESCC22900 (external lab)

- Shipment through AXTAL with CROVEN document package

Alternative 2: Up-Screening of Precision Crystals

Alternative 2: Up-Screening of Precision Crystals

- Procurement of CROVEN crystals through AXTAL

-

-

- Other manufacturers on request

-

- Non ESCC-3501 packages available

- small and SMD packages

- Burn-In Test to ESCC3501

-

- Level B or Level C

-

- Lot Acceptance Test to ESCC3501

- Level 1, Level 2 and/or Level 3

- Evaluation Test IAW ESCC2263501

- … performed by AXTAL Labs

-

- Most tests are in-house, complete document package

Alternative 3: „Space-COTS“ Quartz Crystals

- Guidance in the Selection of suitable COTS Manufacturer

-

- More than 40 years experience and knowledge of the crystal market

- Use of recognized manufacturers

- with Automotive approval, or

- with proven experience in MIL applications

- with established Statistical Process Control (SPC) and Traceability System

- No use of Distributors or „Pseudo manufacturers“!

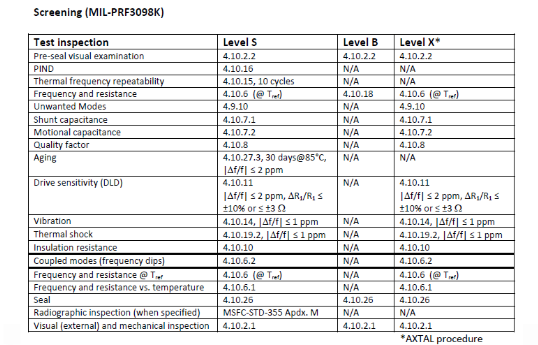

- Up-screening by AXTAL according to MIL-PRF-3098

-

-

- Level S or Level B

-

- Up-screening by AXTAL to slim-lined MIL-PRF-3098

-

- Level „X“

Up-Screening of COTS crystals: „Space-COTS“

CONCLUSIONS

- ESCC3501 is a good guidance for crystals used in space

- For applications with challenges for low cost and short lead time ESC3501/xxx crystals are not appropriate

- Alternatives for COTS applications are

-

- Use of precision crystals screened to ESCC3501 or MIL-PRF-3098 Level S

- Up-Screening of COTS crystals with higher performance (e.g. Automotive grade)

-

-

- MIL-PRF-3098 Screening Level S or B

- Slim-lined MIL-PRF Screening “Level “X”

-

Latest posts by Bernd Neubig (see all)

- COTS quartz crystal units – up-screening for space applications - December 3, 2019

0 comments on COTS quartz crystal units – up-screening for space applications