(Almost Hi-rel) mass production SMD resistor components for Newspace applications

- Posted by Daniel Theis

- On December 3, 2019

- 0

ISA-SPACE @ ACCEDE COTS 2019

Isabellenhütte at a glimpse /

ESCC components /

ESCC vs. AEC-Q200 (Automotive) /

Cost-Down scenario /

Contacts

Isabellenhütte Heusler GmbH & Co. KG

Isabellenhütte Heusler GmbH & Co. KG

- First company documentationary mention in 1482

- Today leading manufacturer for precision alloys, precision and power resistors and precision measurement devices

- Family-owned in the 9th generation

- Company turnover (2018): 170.2 Mil. EUR

- Employees (2018): 950

- 3 international subsidiaries (USA, China, Japan)

- ISO DIN 9001

- IATF 16949

- ISO 14001

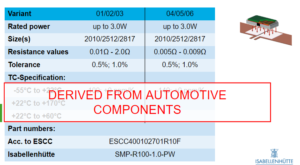

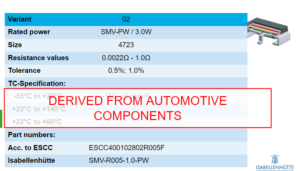

ESCC Detail Specification 4001/027

ESCC Detail Specification 4001/028

ESCC vs. AEC-Q200

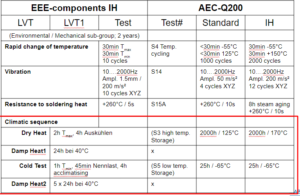

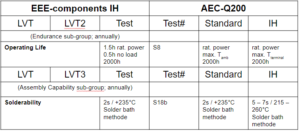

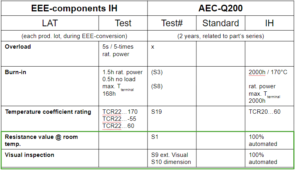

- EEE-components are validated periodically in 24/12-months sequences (LVT acc. to Chart F4); each production lot of an individual EEE-component is tested for compliance of critical properties during the course of the EEE-conversion process (LAT acc. to Chart F3)

- AEC-Q200 qualified components resp. the qualified part‘s series are validated periodically in a 24-months sequence. Due to reasons for cost and approval efficiency these qualification are limited to a few values representing the whole part‘s series.

So what is the true „Space“-capability of Isabellenhütte SMD components?

ESCC vs. AEC-Q200 – Comparison of the qualifications

ESCC vs. AEC-Q200 – Comparison of the qualifications

ESCC vs. AEC-Q200 – Comparison of the qualifications

ESCC vs. AEC-Q200 – Provisional results

- Standard-components (AEC-Q200) of Isabellenhütte do not have an inferior standing compared to the EEE-components in regards to the 24-months-requalification

- Some of the AEC-Q200 tests are performed at more demanding requirements

- Application-critical properties are checked with every single production lot of an EEE-component (LAT) main distinctive feature (along with the SnPb-plated terminals) to the standard-components

Missing resp. updated qualification data of the AEC-Q200 components, as well as LAT data applied to individual production lots can be provided on demand!

Up-to-date AEC-Q200 qualification data of standard Isabellenhütte components can be made available at no cost!

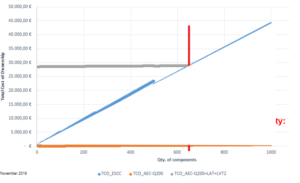

ESCC vs. AEC-Q200 – TCO example

- TCO comparison of an EEE-component (ESCC400102702R01F) versus its Automotive „brother“ SMS-R010-1.0 with up-screening support (+LAT, +LVT2)

ESCC vs. AEC-Q200 – Final results

- Standard-components (AEC-Q200) of Isabellenhütte do not have an inferior standing compared to the EEE-components in regards to the 24-months-requalification

- Some of the AEC-Q200 tests are performed at more demanding requirements

- Application-critical properties are checked with every single production lot of an EEE-component (LAT) main distinctive feature (along with the SnPb-plated terminals) to the standard-components

- Standard-components with up-screening will become more cost-effective as of a certain volume. High cost-saving potential on component level for higher quantities, e.g. > 70% @ 2500 pcs

- Up-screening for risk mitigation can be done on the full Isabellenhütte portfolio of mass-production components

Contacts

0 comments on (Almost Hi-rel) mass production SMD resistor components for Newspace applications