ADS experience vs the selection, procurement and use of automotive parts in space programs

- Posted by Simon Albert

- On November 18, 2019

- 0

Agenda

- Why to use automotive parts in space?

-

- Space Market Evolution

- Meeting the requirements

-

- AEC-Q Principles

-

- Production Part Approval Process (PPAP)

- Comparing Hi-Rel and Automotive Standards

-

- Selection of Automotive Components for Space

- Procurement of Automotive Components for Space

- Use of Automotive Components for Space

- Main Takeaways

Why to use automotive parts in space? – Space Market Evolution

- the use of automotive parts in space programs seems to be beneficial due to the change of needs in the space market

-> Changing needs call for new approaches / methodologies / concepts

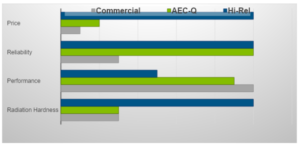

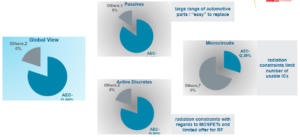

Why to use automotive parts in space? – Meeting the requirements

- to what degree do different kind of parts meet the requirements for space programs

- automotive components are the best compromise between price & reliability (excluding radiation) for space

-> AEC-Q components provide a good compromise between price & reliability for space programs (excluding radiation)

AEC-Q Principles

- AEC-Q documents specify how to qualify components and to requalify them in case of material or process changes.

- There is no AEC Qualifying Body, auditing the manufacturers or certifying it has met the qualification requirements:

- Manufacturers self-certify their compliance to AEC-Q requirements

- Each user is responsible to review the qualification data to verify the compliance to AEC-Q requirements

- Quality is based on:

- Heavy qualification procedure (several hundreds of parts)

- Determination of Early Life Failure Rate (ELFR) – for microcircuits

- Strict control of material and process changes

- SPC (Statistical Process Control) based on volume

- Different grades of components are defined according to their temperature range with associated qualification tests.

- Grade 0 : -40C to +150C (microcircuits) or -50C to +150C (passive)

- Grade 1 : -40C to +125C (microcircuits & passive)

- Grade 2 : -40C to +105C (microcircuits & passive)

- Grade 3 : -40C to +85C (microcircuits & passive)

- Grade 4 : 0C to +70C (passive – non-automotive)

- As a result:

- No screening process is imposed.

- No periodic lot qualification is required.

Production Part Approval Process (PPAP)

- PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.

- There are 5 levels of PPAP submission. Generally Automotive uses the level 3 : Part Submission Warrant (PSW) with product sample and complete supporting data.

- The PPAP process consists of 18 elements that may be required for approval of production level parts. Not all of the elements are required for every submission.

- Design Documentation

- Engineering Change Documentation

- Customer Engineering Approval

- Design Failure Mode and Effect Analysis (DFMEA)

- Process Flow Diagram

- Process Failure Mode and Effect Analysis (PFMEA)

- Control Plan

- Measurement System Analysis Studies

- Dimensional Results

- Records of Material / Performance Tests

- Initial Process Studies

- Qualified Laboratory Documentation

- Appearance Approval Report

- Sample Production Parts

- Master Sample

- Checking Aids

- Customer Specific Requirements

- Part Submission Warrant (PSW)

- The resulting PPAP submission provides the evidence that the supplier has met or exceeded the customer’s requirements and the process is capable of consistently reproducing quality parts.

- Contrary, in space, CoC (Certificate of Compliance) certifies that a series of tests has been done. It does not warrant a failure rate of components.

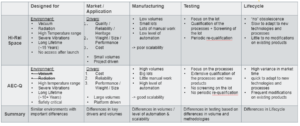

Comparing Hi-Rel and Automotive Standards

Comparing Hi-Rel and Automotive Parts – A Summary

-> make use of the advantages & manage the differences!

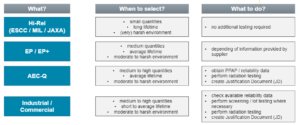

Selection of Automotive Components for Space

-> it’ not about either … or …, it’s about both … and …!

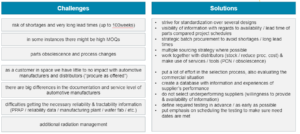

Selection of Automotive Components for Space

- two experiences when selecting automotive parts:

- overall it is important to put high emphasis on the selection process

-

- strive for standardization (PPL / EEE Roadmap)

- well connected multifunctional teams required

-

- connecting experts with regards to radiation, EEE parts, design, manufacturing, testing, procurement & customer support

-

- have clear requirements / establish reliable & efficient processes for additional testing

- make sure data & information is stored and well accessible

-

Procurement of Automotive Components for Space

Use of Automotive Components by ADS in New Space programs

Main Takeaways

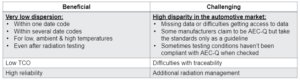

- AEC-Q parts are a good alternative for usage in space programs

-

- low price / high reliability / very low dispersion

- there are inherent differences between AEC and Hi-Rel methodologies, which have to be managed

- there are a variety of component levels available! It’s the challenge of the user to identify what the best fit for the parts need is (Hi-Rel / EP / AEC-Q / Commercial)

-

- Put high emphasis on the evaluation & the selection process of parts

-

- strive for standardization (PPL / EEE Roadmap)

- well connected multifunctional teams required

-

- connecting experts with regards to radiation, EEE parts, design, manufacturing, testing, procurement & customer support

-

- have clear requirements / establish reliable & efficient processes for additional testing

- make sure data & information is stored and well accessible

-

- Experiences made with “automotive” parts

-

- “automotive” / “automotive qualified” / “automotive applications” is often not “AEC-Q xxx”

-

- Some manufacturers states that AEC-Q is taken only as a guideline

- Some manufacturers declare to be AEC-Q qualified but no data is available on their websites or upon request

- Some testing conditions of procured parts haven’t been compliant to AEC-Q requirements when checked

- due to the limited volume in space we experienced difficulties in receiving the necessary information (e.g. PPAP)

-

- “automotive” / “automotive qualified” / “automotive applications” is often not “AEC-Q xxx”

-

-> responsibility of the buyer to check documentation and adherence to AEC standards

-> need for Justification Document for AEC-Q parts

The Authors

0 comments on ADS experience vs the selection, procurement and use of automotive parts in space programs