Capacitor Technologies Overview

- Posted by doEEEt Media Group

- On February 22, 2023

- 0

The article provides quick capacitor technologies overview and their main position on voltage/capacitance range.

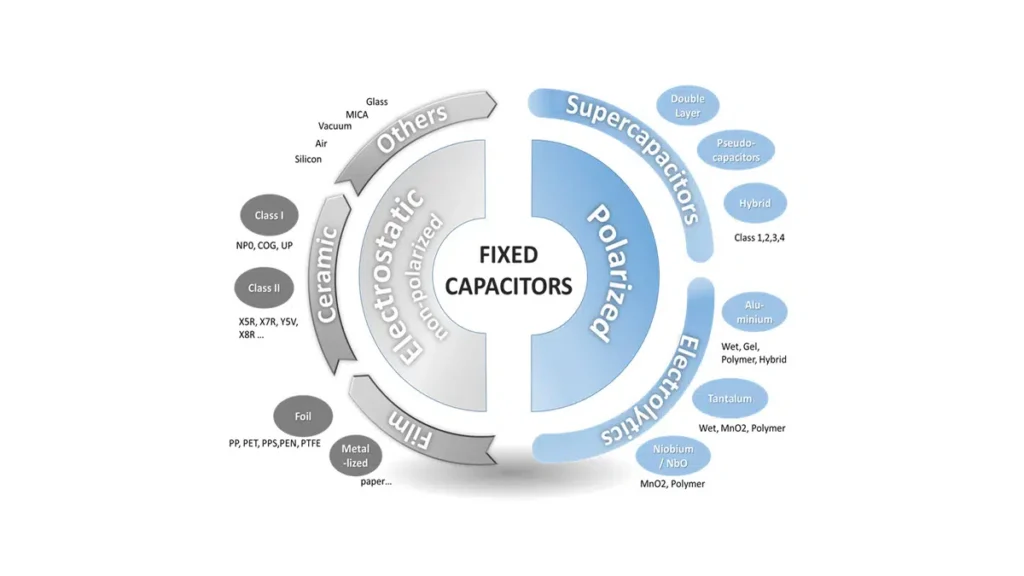

There are multiple views possible on how to sort and split capacitor technologies. The major group of fixed (non-variable) capacitors can be divided into two groups depending on whether the capacitors are polarized (with plus positive and minus negative electrodes) or non-polarized. Non-polarized capacitors are closer to a simple capacitor model M-I-M (metal – insulator – metal) dominated by electrostatic charge storage, and thus it can be also called “electrostatic” capacitors. See figure 1 chart fix capacitor types.

Figure 1. fixed capacitor types, source: EPCI

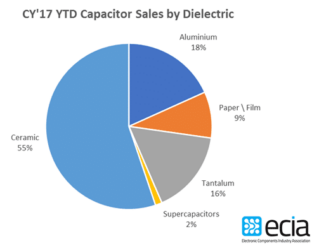

Ceramic capacitors are leading miniaturization, downsizing, and dominating the market share. The right charts are based on sales VALUE, but if we have these charts in sales VOLUME, ceramic capacitors will occupy up to 80% of the market share of all capacitors made; on the other hand, more expensive tantalum capacitors would shrink their share in volume terms. The biggest dynamic exhibits supercapacitors, its market share in 2015 was negligible, while the 2017 share reached 2% and continues to grow.

Capacitor Technologies

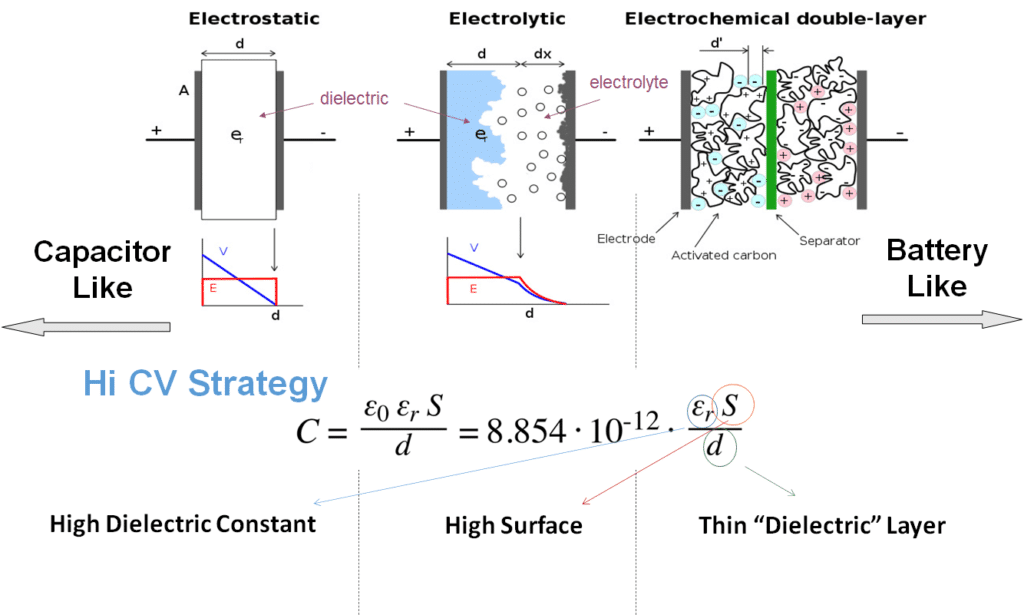

We can split fixed capacitor technologies further into three main groups that substantially differ in their construction and features:

- Electrostatic Capacitors

- Electrolytic Capacitors

- Supercapacitors (electrochemical capacitors)

Figure 2. capacitor technologies value market share in 2017; source: ECIA

Figure 3. capacitor technologies comparison; source: EPCI

These are the “typical” capacitors as we can imagine at the first moment with a “conventional” construction Metal – Insulator – Metal consisting of two electrodes separated by a dielectric material. The capacitor is non-polar so it does not matter how these are connected to the circuit and it can be also used at AC voltage (just note AC and DC voltage ranges may differ as we discussed in the first part of the course). The high capacitance value is achieved by the selection of materials with high permittivity (ceramic class II materials). High withstand voltage is achieved by the selection of dielectric materials with high dielectric strength (organic film materials) – but of course permittivity and capacitance are lower.

These capacitors are achieving very high capacitance values due to the formation of a very high surface of the electrode. Such a very fine, etched/microporous high surface area is however very difficult to contact from the second side, thus a conductive medium-electrolyte is used to enable electrical contact to such a surface. Downsize of this configuration is that it works in one direction – so these are polar DC devices, the internal structure has higher losses that also may impact its frequency and temperature dependency.

Supercapacitors are, in fact, not “true capacitors” but a structure with features between capacitors and batteries. There is no classical dielectric layer; its capacitance is created by a charge on the electrode interface. The charge is accumulated just within a few atomic layers, and thus the “virtual dielectric” is very thin, resulting in a huge capacitance value. However – the structure is limited to cell voltage (between 0.8 and 3V typically), and it is only DC with limited AC operation. Thus it is suitable as a DC energy storage capacitor, but it can not be used like AC filtering capacitor in DC/DC converters.

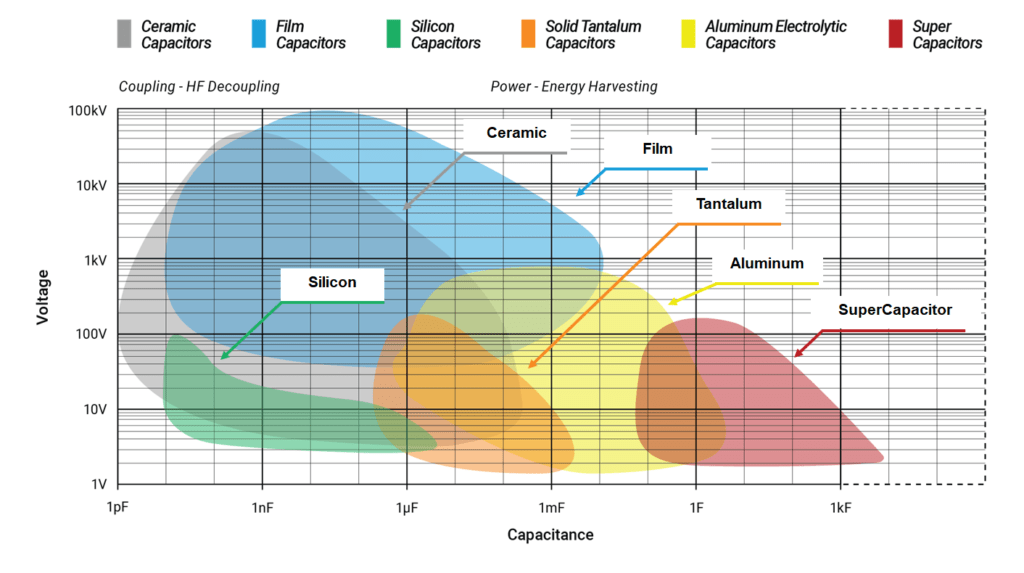

Capacitor Technologies Capacitance versus Voltage Capabilities

Finally, for the introduction, here is an overview of the capacitance versus voltage capability of the main capacitor technologies in the mass volume market:

Figure 4. Capacitor technology capacitance versus voltage capabilities; source: EPCI

Resource: Passive components Blog

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Capacitor Technologies Overview