Capacitor for Coupling and Decoupling Applications

- Posted by doEEEt Media Group

- On June 26, 2024

- 0

Simon Ndiritu explains some basic capacitor selection guides for coupling and decoupling applications.

Capacitors are fundamental components in both analogue and digital electronic circuits. These passive components play an important role in influencing the operational behaviour of circuits. A capacitor’s characteristics vary mainly depending on the dielectric material used. The dielectric material determines a capacitor’s capacitance value, energy efficiency, and size. Fixed-value capacitors can be broadly categorized into two categories: polar (electrolytic) and non-polar (electrostatic) capacitors. Non-polar capacitors include ceramic, film, and paper capacitors. Aluminium electrolytic capacitors and tantalum capacitors are polar components.

In circuits, capacitors are used for a wide range of applications, including storing electrical charges, blocking DC components, bypassing AC components, filtering unwanted signals, and so on. A capacitor’s applications primarily depend on its characteristics. When selecting a capacitor for a given application, key properties include capacitance value, voltage rating, frequency response characteristics, cost, and physical size. Other capacitor properties that can influence an electronic circuit’s performance include temperature characteristics, self-healing properties, ageing, and flammability.

Coupling capacitors

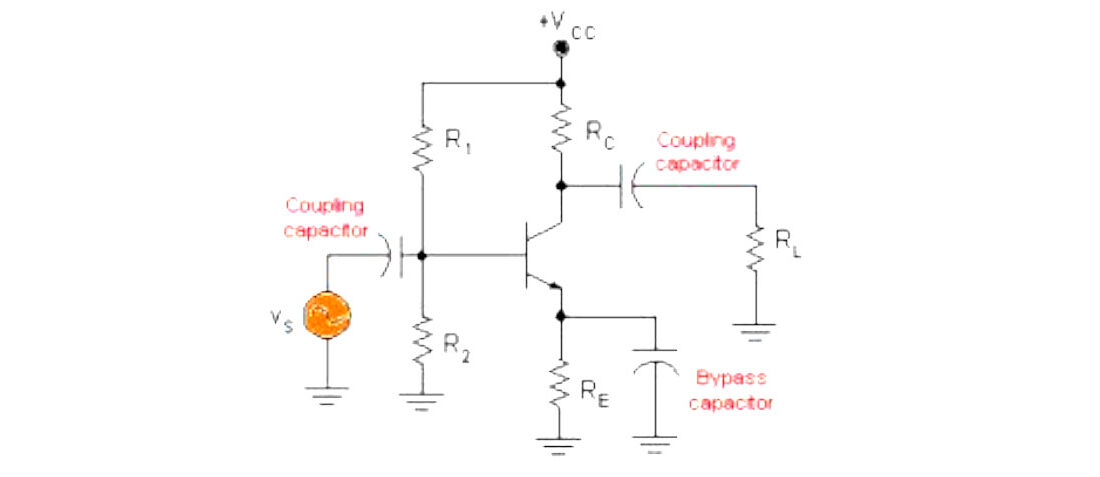

Coupling capacitors are used in electronic circuits to pass the desired AC signal and block unwanted DC components. These unwanted DC signals come from electronic devices or preceding stages of an electronic circuit. In audio systems, DC components affect the quality of the desired signal by introducing noise. Furthermore, DC signals affect the performance of power amplifiers and increase distortion. A coupling capacitor is connected in series with the signal path in circuits. Coupling capacitors are used in analogue and digital electronic circuits. They find many applications in audio and radio frequency systems.

The reactive nature of a capacitor allows it to respond to different frequencies differently. In coupling applications, a capacitor blocks low-frequency DC signals and allows high-frequency AC signals to pass. To low-frequency components, such as DC signals, a capacitor exhibits high impedance, thereby blocking them. On the other hand, a capacitor exhibits low impedance to high-frequency components, allowing high-frequency signals, such as AC components, to pass.

In audio systems, DC sources power audio circuits. However, since the audio signal is usually an AC signal, the DC component is unwanted on the output. To prevent the DC signal from appearing on the output device, a coupling capacitor is added in series with the load.

Coupling capacitors are essential components in amplifier circuits. They prevent interference of a transistor’s bias voltage by AC signals. In most amplifier circuits, this is achieved by driving the signal to the base terminal of a transistor through a coupling capacitor. When a capacitor with the correct capacitance value is serially connected, the sound signal can pass while the DC component is blocked.

The presence of DC components on a transmission line can significantly affect the performance of a digital circuit. In communication systems, coupling capacitors are used to block unwanted DC components. Blocking the DC component helps to minimize energy loss and prevent the accumulation of charge in digital circuits.

Types of capacitors for coupling applications

When selecting a capacitor for coupling/DC blocking applications, the fundamental parameters include impedance, equivalent series resistance, and series resonant frequency. The capacitance value primarily depends on the frequency range of the application and the load/source impedance. The capacitors commonly used for coupling applications include film, ceramic, tantalum, aluminium electrolytic, and aluminium organic/polymer electrolytic capacitors.

Tantalum capacitors offer high stability at high capacitance values and are available in different variants. Compared to ceramics, these capacitors have higher ESR and are more expensive. For coupling applications, tantalum capacitors are more popular than ceramic capacitors.

Aluminium electrolytic capacitors are cheaper than tantalum capacitors. They offer stable capacitance and similar ESR characteristics to tantalum capacitors. However, these capacitors are relatively large and not recommended for circuits with limited circuit board space. Aluminium electrolytic capacitors are widely used for coupling applications in power amplifiers.

Ceramic capacitors are inexpensive and available in small SMT packages. They are cheaper than tantalum capacitors. Although ceramic capacitors are commonly used in audio and RF applications, they are generally unsuitable for applications that demand superior performance.

Film capacitors’ large physical sizes limit their applications in AC coupling. If space is not an issue, polypropylene and polyester capacitors have characteristics that make them good choices for coupling applications in pre-amp circuits.

Decoupling capacitors

Some electronic circuits are highly sensitive to voltage spikes, and rapid voltage changes can greatly affect their performance. Electronic circuits use decoupling capacitors to prevent quick voltage changes by acting as electrical energy reservoirs. In case of a sudden voltage drop, a decoupling capacitor provides the electrical energy required to maintain a stable voltage supply. On the other hand, if there is a sudden voltage spike, the capacitor stabilizes voltage by absorbing the excess energy.

Apart from stabilizing voltage in electronic circuits, decoupling capacitors allow DC components to pass while shorting AC components to the ground. Capacitors used for bypassing AC noise in electronic circuits are also commonly known as bypass capacitors. Bypass capacitors absorb AC noise to produce a cleaner DC signal.

A bypass capacitor is placed parallel to a resistor to remove AC noise. A capacitor offers high resistance to low-frequency signals and less resistance to high-frequency signals. As such, low-frequency DC components use the resistor path while high-frequency AC components are shunted to ground through the bypass capacitor. This yields a clean DC signal that is free from AC components.

Types of capacitors for decoupling applications

When selecting a capacitor for decoupling applications, it is critical to consider the electrical requirements of the design. The key parameters to consider when selecting a bypass capacitor include the lowest frequency of the AC signal and the resistance value of the resistor. In most cases, the lowest frequency is 50 Hz.

Although different capacitors are available for decoupling/bypassing applications, their characteristics vary markedly depending on the dielectric material used and structure. The two determine temperature stability, linearity, voltage rating, physical size and cost. The capacitors commonly used for decoupling applications include ceramic, tantalum, and aluminium electrolytic capacitors.

The performance and cost of ceramic capacitors make them a popular option for decoupling applications. These capacitors have low equivalent series resistance (ESR) and equivalent series inductance (ESL). In addition, multi-layer ceramic capacitors (MLCCs) are available in various packages and capacitance values. Ceramic capacitors are an excellent option for decoupling applications in HF circuits.

Switching-type aluminium electrolytic capacitors are commonly used for decoupling applications in low-frequency and medium-frequency electronic circuits. These capacitors are inexpensive, available in a wide range of capacitance values, and have a high capacitance-to-volume ratio. However, aluminium electrolytic capacitors exhibit temperature-related wearout and have high ESR at low temperatures. These capacitors are widely used for decoupling applications in consumer products.

Solid tantalum capacitors have high CVs and are less susceptible to wear out. Furthermore, they exhibit impressive stability at low temperatures. Compared to aluminium electrolytic capacitors, tantalum capacitors have higher capacitance-to-volume ratios and lower ESR. Contrastingly, tantalum capacitors are expensive and limited to low voltage applications. Usually up to 50 V. These capacitors are commonly used in higher reliability applications.

Film capacitors such as polyester, polypropylene, Teflon, and polystyrene capacitors have limited decoupling applications. Although these capacitors are suitable for high-voltage applications and are less susceptible to wear out, the cost of producing them is relatively high. Nevertheless, the characteristics of these capacitors make them suitable options for high voltage, high current, and audio decoupling applications.

Conclusion

Capacitors are fundamental components in both analogue and digital electronic circuits. They are used for various applications, including coupling, decoupling, filtering, and timing applications. Coupling capacitors allow AC components to pass while blocking DC components. Decoupling capacitors are used in electronic circuits as energy reservoirs to prevent quick voltage changes. Bypassing capacitors clean DC signals by shunting unwanted AC components to the ground. A capacitor significantly determines the performance, lifetime, and reliability of an electronic circuit. As such, it is advisable to use high-quality components, preferably from franchised distributors or directly from the manufacturer.

Choose the best option for your design using the comparation tool of doEEEt

>> CLICK HERE TO NAVIGATE

>PLASTIC METALLIZED CAPACITORS

Source: Passive Components

- Space-Grade components available for immediate delivery - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

- Filtering Characteristics of Parallel-Connected Fixed Capacitors in LCC-HVDC - November 21, 2024

0 comments on Capacitor for Coupling and Decoupling Applications