Capacitance Package, Minimizing Footprint while Maximizing

- Posted by Kemet Electronic Corporation

- On April 17, 2020

- 0

KEMET KONNEKT™ Capacitance Package allows two to four ceramic capacitors to be stacked vertically or horizontally while retaining the integrity of the part. It uses transient liquid phase sintering (TLPS) technology to bond component terminations together. The KONNEKT™ U2J capacitors can be used in both orientations, thus minimizing the component footprint, while maximizing the bulk capacitance of a stacked MLCC with design flexibility in mind.

Just when you thought we were done with our “KEMET-ized” sensational spelling, we released KONNEKT™ with not just one “k”, but two! We just can’t help ourselves. All jokes aside, this revolutionary packaging solution was created to solve the problem of component selection in the growing trend of design minimalization. A few years ago we were involved in a major open-source project for a well-known tech giant with an interesting problem. They required a low loss, low inductance package capable of handling extremely high ripple current. The requirements also included the fact that their product would be using 48 V power architecture while taking up a very small footprint on the board.

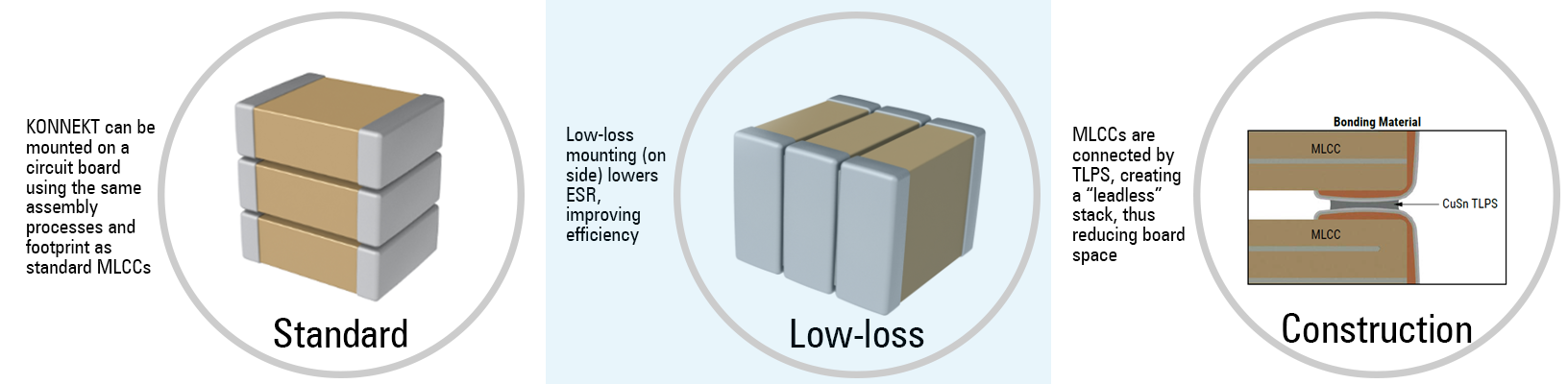

Kemet Engineering began the process of brainstorming what would later be labeled as their KONNEKT™ U2J ceramic capacitor. Similar to the construction of high rises and skyscrapers in major metropolitan areas, one creative and commonly used answer for space limitation is to build from the floor up in a vertical or standard orientation. Because of the requirement of the application and space limits, our stacked MLCC solution was placed in a horizontal configuration, known as a “low-loss orientation.” The KONNEKT™ U2J product can be used in both orientations, thus minimizing the component footprint, while maximizing the bulk capacitance of a stacked MLCC with design flexibility in mind.

KONNEKT U2J low-Loss and standard orientation

KONNEKT™ Capacitance Package Technology

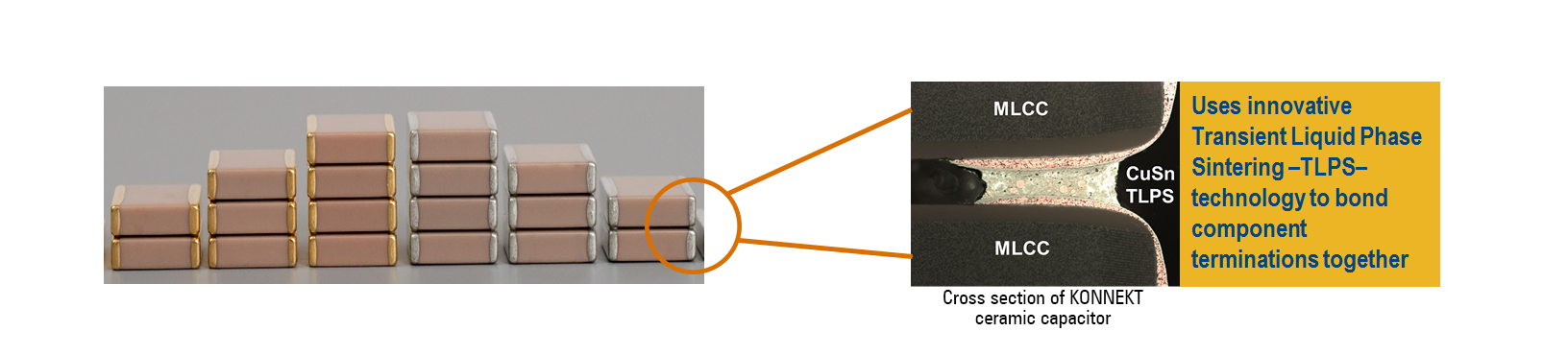

Our patented KONNEKT™ Capacitance Package allows two to four ceramic capacitors to be stacked vertically or horizontally while retaining the integrity of the part. It uses transient liquid phase sintering (TLPS) technology to bond component terminations together. TLPS is a metal matrix composite bond that features copper-tin material and is used as a replacement for solder. The unique composite uses tin which is a low-temperature reaction metal at 300°C, with copper as the high melting point metal at 1085°C to form a reacted metal matrix, creating a distinct advantage over the use of solder. The TLPS forms a metallurgical bond between two surfaces, in this case, our U2J MLCC.

TLPS is reacted metal matrix that forms a metallurgical bond between 2 surfaces, in this case, two MLCCs

Why U2J?

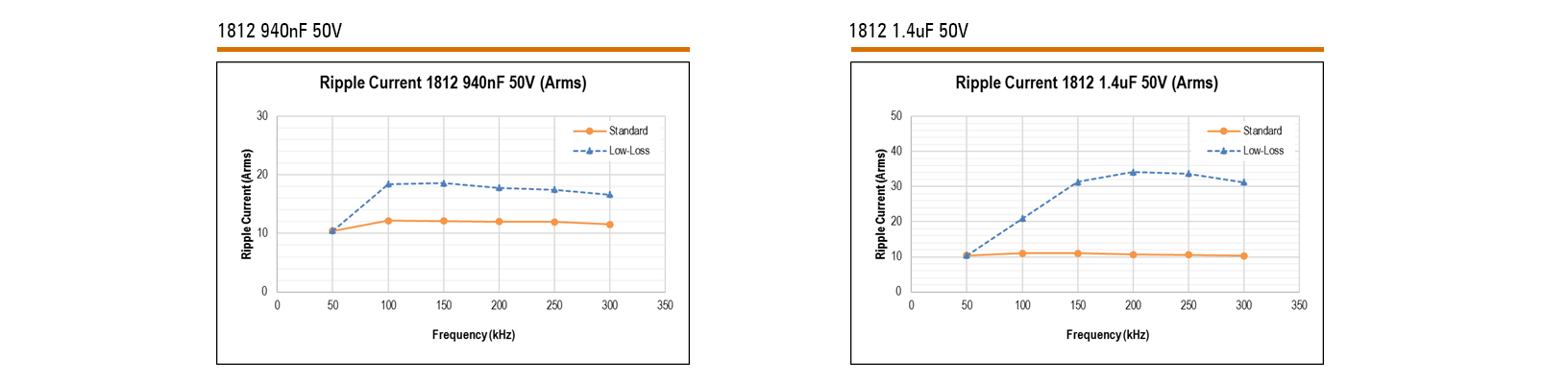

We designed the solution for our customer using our U2J ceramics because of its Class 1 properties. Our U2J ceramic capacitors are extremely stable and retain over 99% of nominal capacitance at full rated voltage. When referenced to ambient temperature, U2J ceramic capacitors provide a predictable and linear change in capacitance. Additionally, U2J ceramic capacitors extend the available capacitance of Class 1 MLCCs into a range previously only available to Class II dielectric materials such as X5R and X7R. Combined with KONNEKT™ packaging technology, this little SMD offers bulk capacitance with extremely high ripple current capability.

Ripple current measurements performed at 85°C with a peak capacitor temperature of 95°C. Samples mounted to heat sink with no forced air cooling. Maximum ambient and self-heating cannot exceed 125°C.

Source: Kemet Engineering Center article

Contact us

- Decoding The DC-Link - June 8, 2022

- High Reliability: Tantalum Capacitors on the Front Lines of Defense - June 3, 2022

- One Turn Inductors Explained - March 24, 2022

0 comments on Capacitance Package, Minimizing Footprint while Maximizing