How to protect your COTS parts during C-SAM inspections

- Posted by Francisco Javier Aparicio Rebollo

- On July 7, 2020

- 0

The current post describes the different measures taken during Scanning Acoustic Microscopy (C-SAM) inspection to avoid potentially harmful effects on your COTS parts, associated with water immersion. An internal visual inspection conducted after decapsulation shows the successful prevention of corrosion phenomena in these samples.

ALTER has acquired for 30 years, solid and considerable experience of inspection and testing of both high reliability and COTS parts. This provides us with the knowledge to preserve the component under test at the best conditions.

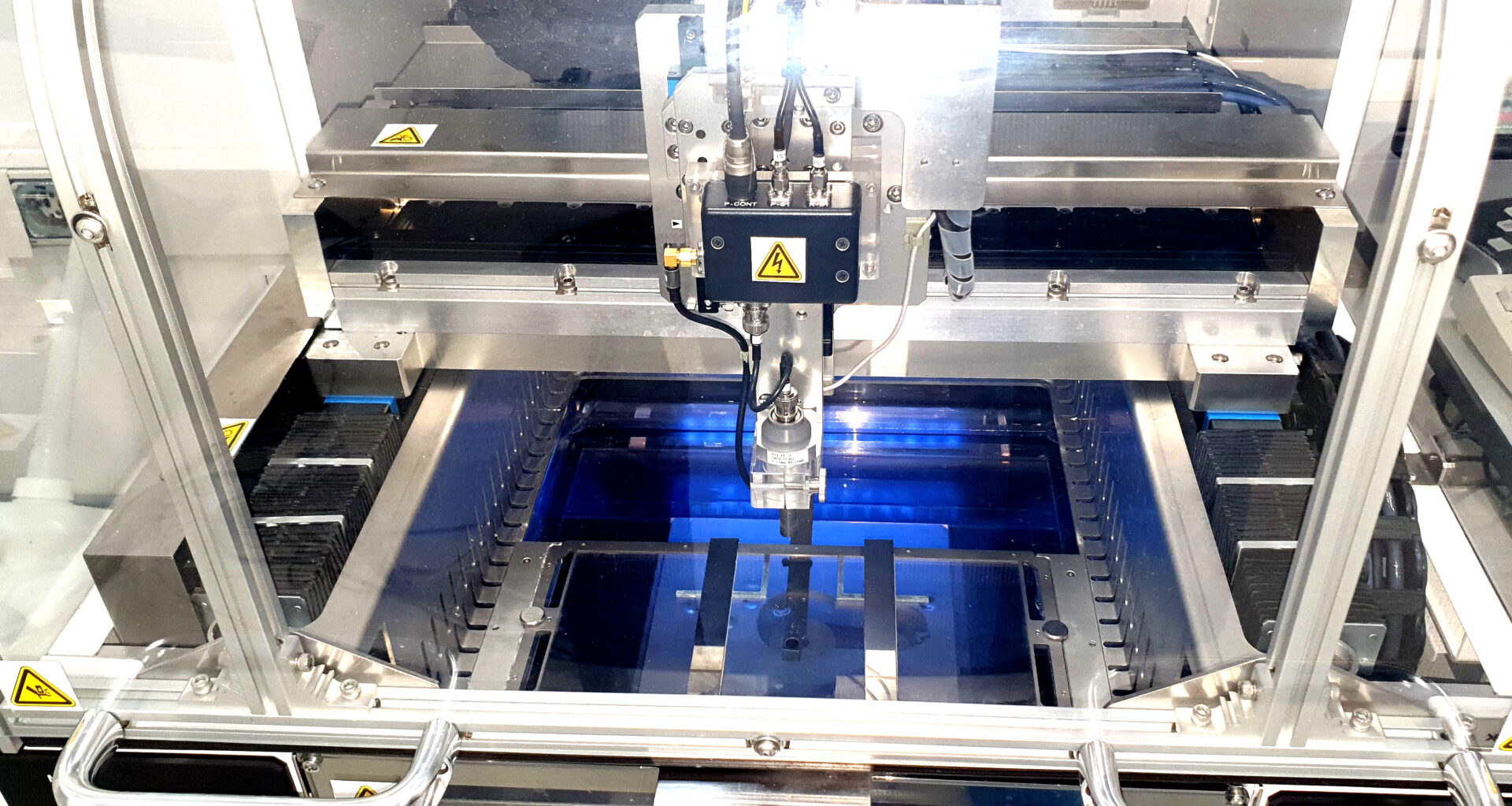

Confocal Scanning Acoustic Microscopy makes use of ultrasound pulse to image the internal structures and defects within COTS plastic packages. The working principle is based on the strong reflection that the ultrasound beam experiences at solid/gas interfaces (air cavities/delamination). Hence, both the ultrasound probe and the sample under test must be immersed during the inspection in a liquid coupling media, typically water. Otherwise, the ultrasound signal is fully reflected at the transducer output/air interface, so it does not enter the sample.

COTS PARTS protection

For some applications, water immersion during SAM inspection may be a common concern due to the lack of hermeticity of plastic COTS parts. This is mainly related to:

- The risk of ingress of ionic contaminations or other agents activating internal corrosion processes.

- The risk of popcorn carking during soldering due to the remaining internal moisture.

In accordance with our internal procedure and the different C-SAM test methods systematically take the following measures to protect your COTS parts

- The inspection is always conducted in low conductivity de-ionized water to avoid exposure to ionic contaminants, in accordance with our internal procedure and most of the SAM inspection methods included below

Surprisingly, the test the specification J-STD-022 does not provide any guidelines in terms of the purity of the water used for SAM inspections whereas ESCC25200 only indicates that the inspection must be performed in “clear water”. In contrast, the NASA test method PEM-INST-001 indicates that deionized water should be used for the inspection of flight parts. In accordance with our internal procedure, all the inspections are conducted in de-ionized water, either for flight parts or not.

Optionally the inspection can be conducted in a fluoro-carbon liquid such as those used in the gross-leak test.

- The immersion time is limited to the minimum required to acquire high-quality images and representative A-scans. With this aim, we frequently make use of other non-destructive inspection techniques (e.g. X-ray inspection) to get the first insight into the internal structure and therefore decrease the focalization time.

- To remove the potentially remaining moisture within the package we offer to our customers the possibility of a gentle drying and air-circulating oven specifically devoted to these operations. This precaution is taken in accordance with MIL-STD-883 TM2030 to avoid the risk of popcorn cracking during a subsequent soldering process. In this regards the specification J-STD-033 provides the guidelines to dry the samples before assembly, depending on the component thickness, and moisture sensitive level.

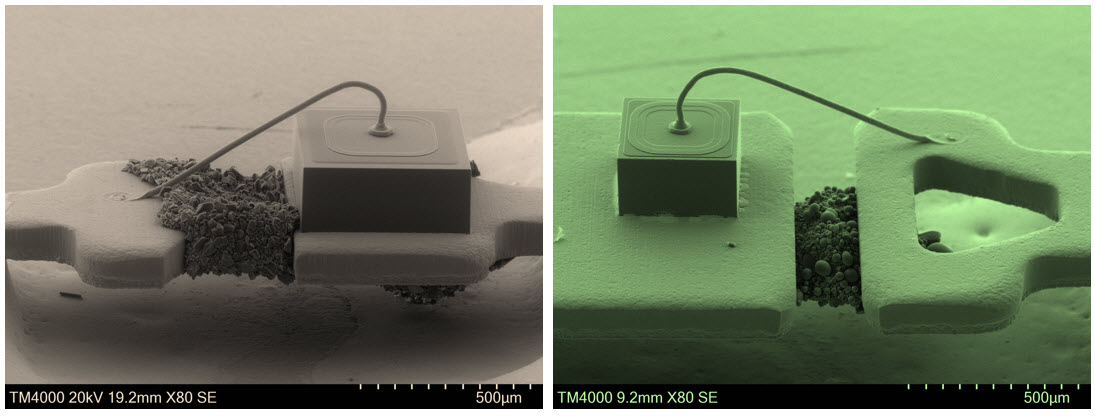

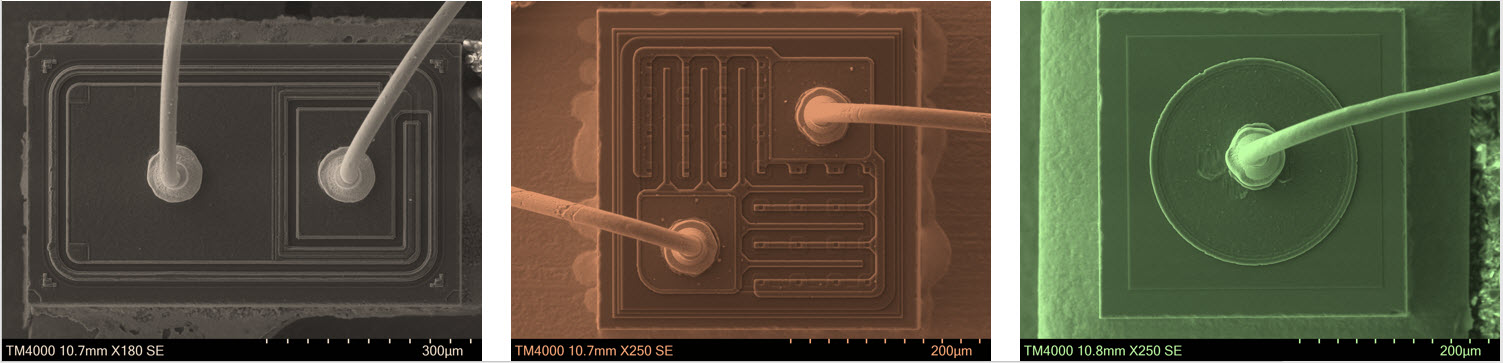

To illustrate the suitability of the used combined approach the following pictures show the result of the internal SEM inspection conducted in different COTS parts after two SAM inspections (SAM + TC + SAM). The images show how thanks to these precautions the samples show no signs of corrosion of the metallic parts or other kinds of anomaly related to the immersion in water. The imagine gathers three examples of small diodes, where there is a higher risk of water diffusion towards the active area, due to the thin package.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Material Analysis Techniques for Electronic Components - May 6, 2022

- SAM: Survey to manufacturers and users - February 17, 2022

- What is a C-SAM Inspection? - January 29, 2022

0 comments on How to protect your COTS parts during C-SAM inspections