Requirements for COTS components usage on JAXA

- Posted by Akifumi Maru

- On December 3, 2019

- 0

- Introduction

- Requirements for COTS components usage on JAXA

- Case study of consideration about COTS component usage for launch vehicle

- Recent Activities

- Single event test methods for AD/DA

- Coating evaluation for the purpose of preventing the whisker growth

- Summary

Introduction

- Due to its advanced performances and cost saving, use of COTS components has been considered in the applications not only for the “NEW SPACE” satellites but also for JAXA’s spacecraft.

- JAXA has also been examining the possible use of COTS components and clarifying the conditions and specifications.

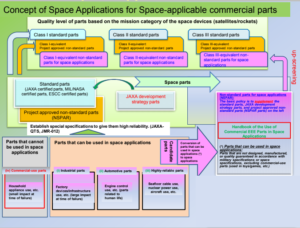

- “Handbook of the Use of Commercial EEE Parts in Space Applications” which consists of the conditions and evaluation methods for each of four classified mission criteria for the purpose of utilizing the COTS components is established.

Today’s Topics!!

- Introduction of the four types of COTS usage handbooks in JAXA

- Case study of consideration about COTS component usage for launch vehicle

- JAXA’s recent activity about COTS components

“Handbook of the Use of Commercial EEE Parts in Space Applications”

- There are four kinds of “Handbook of the Use of Commercial EEE Parts in Space Applications” in JAXA* (* JERG-0-052A, JERG-1-010, JERG-2-023, JERG-2-024).

For “long life satellite”, “science satellite”, “rockets” and “general” - These documents are based on a policy to maintain sufficient reliability and quality of COTS components on each mission category in terms of up-screening, basically.

- Due to above policy, there are some prerequisites listed below.

- COTS components stated in these handbooks are high reliability components (such as the components for auto-motive, industrial, medical or infrastructures).

- Exchange the documents (detail specification, internal structure, materials, traceability, failure rate, etc.) with COTS manufacturer for the purpose of obtaining the information about the products.

Current situation and issues

- According to our handbooks, the approach of space application for COTS is

-

- Categorize: Project is categorized into mission categories based on mission criticality and use condition of components.

- Up-screening: The candidate COTS which were selected from high-reliability components undergo up-screening and are categorized into suitable component class.

- Adopt: The components are applied for the project as non-standard components.

- Issues

- Cost for up-screening (also including time)

- Extremely difficult to get the cooperation of components manufacturer. (because space customers don’t need the large quantity, generally)

- COTS component manufacturer usually set a “minimum buy” for purchase. (may be, this is only for Japanese case)

We need to establish the guideline to specify appropriate, simple and easy evaluation methods for COTS.

Case study of consideration about COTS component usage for launch vehicle

One of the ideas to address the issue is “Automotive components”. Here shows the example of COTS selection for launch vehicle.

H3 launch vehicle

- Next generation launch vehicle of JAXA

- Available in 2020.

Policy:

Policy:

- High flexibility

- provide more launch opportunity for the user

- High reliability

- inherit the success rate of H-IIA rocket

- Great cost-performance (good value)

- realize the low cost by reducing electronic components cost, for example COTS component utilization

Avionics system of H3 utilized COTS components based on automotive components

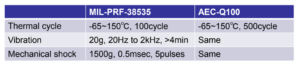

- As prerequisites, candidate components were approved by AEC-Q100.

- Test specification of AEC-Q100 are equal or greater than MIL-spec excepting radiation test.

- Product process management is guaranteed by ISO/TS16949.

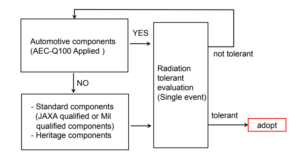

- Because they are for a launch vehicle, the components need radiation evaluation only for “Single event”.

H3 EEE components selection flow.

Based on the above flow, approximately 90% components for H3 avionics system successfully replaced by the COTS.

Recent Activities

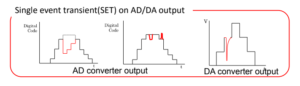

Single event test methods for AD/DA

- To establish appropriate evaluation methods for COTS, JAXA have started to investigate the applicability of COTS with the latest technologies.

✓ This is a serious problem on image sensing components (such as star tracker).

✓ In particular, this event becomes more serious on latest high speed components.

✓ There is no detail specification to evaluate such analog devices

✓ High cost for preparing test environment (such as test board or measurement equipment)

Recent Activities

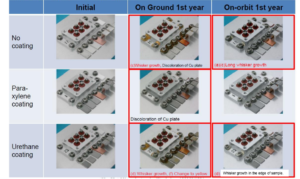

Coating evaluation for the whisker growth

- Due to the demands for applying COTs components to space application, we need to know whether lead-free components are applicable for in-orbit environment.

- To apply the lead-free components for space, “whisker” is the most important and biggest barrier.

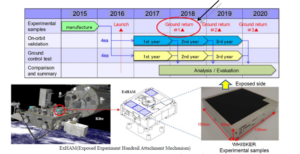

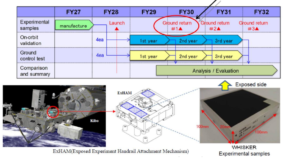

- JAXA planed 3-year WHISKER mission for in-orbit demonstration.

- This demonstration is performed by ExHAM platform equipped on Kibo module in ISS.

- The 1st year sample came back last year. The results of exposure were analyzed and compared to the ground test results.

- Different to the whisker observed in ground test sample, which was less than 100um long, the longest whisker in orbit sample was about 440um long.

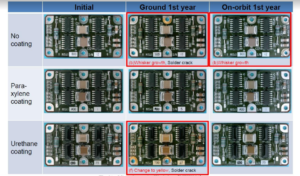

- Para-xylene coating: There is no growth of whiskers either on ground or in-orbit. (surface unchanged)

- Urethane coating: There is no growth of whiskers in thick coated area.

- It was found that there is the winkles and thinner coating around the edge of samples.

It should be monitored carefully whether whisker will grow on the 2nd and 3rd year.

- It was found that there is the winkles and thinner coating around the edge of samples.

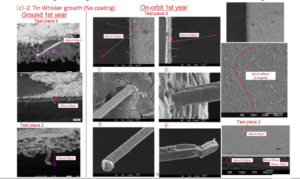

- No coating: There is growth of whiskers in both cases.(Different shape and length)

Based on the 1st year test sample evaluation results, tin whisker suppression effect of both Para-xylene and Urethane coating was confirmed.

Summary

- JAXA have four kinds of “Handbook of the Use of Commercial EEE Parts in Space Applications”

- COTS can have sufficient reliability and quality by up-screening procedure of above handbooks.

- On the other hand, there are some issues in regard to cost and prerequisites.

JAXA is currently in the process of working on the guideline appropriate to evaluate the COTS in more easy and simple way.

- Case study of automotive components adoption for the launch vehicle

- According to component selection flow, components which are based on AEC-Q100 were adopted to H3 launch vehicle.

- 90% components of H3 avionics system were successfully replaced by the COTS.

- JAXA’s recent activity about COTS components

- Radiation evaluation methods for AD/DA converter with GHz clock.

- Coating evaluation for the whisker growth

APPENDIX

Background of WHISKER mission

- Due to the demands for applying COTs components to space application, we need to know whether lead-free components applicable for in-orbit environment.

- To apply the lead-free components for space, “whisker” is the most important and biggest barrier.

JAXA started the in-orbit demonstration calls “WHISKER mission“.

-

-

- To verify the effectiveness of conformal coating for tin whisker suppression in-orbit environment.

- To identify the different of whisker growth between on-ground and in-orbit environment.

-

Interim report of WHISKER mission

- JAXA is planning to 3 years WSHISKER mission for in-orbit demonstration.

- This demonstration is performed by ExHAM platform equipped on Kibo module in ISS.

- 1st year sample was back in last year. The results of exposure were analyzed and compared to the ground test results.

- We have two objectives of WHISKER mission

-

- To verify the effectiveness of conformal coatings which may mitigate whisker growth.

- To compare whisker growth on the ground and on-orbit using the same sample.

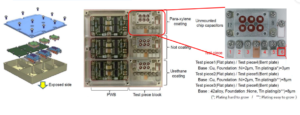

To achieve above objective, we prepared test samples of PWB and Test pieces which different of coating condition.

Summary of results (PWB)

Summary of results (Test pieces)

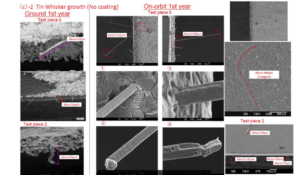

Microscope inspection (Test piece block)

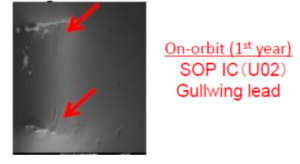

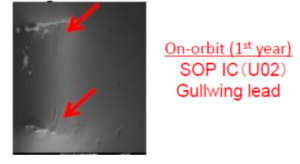

Results of Surface observation by SEM (Test piece block)

- Different to the whisker observed in ground test sample, which length was less than 100um, the longest whisker was about 440um length in in-orbit sample.

Effectiveness of conformal coating

- Para-xylene coating: There is no growth of whiskers in either case. (surface unchanged)

- Urethane coating: There is no growth of whiskers in thick coated area.

- It was found that there is the winkles and thinner coating around the edge of samples.

It should be monitored carefully whether whisker will be growth on 2nd and 3rd year.

- No coating: There is growth of whiskers in both cases.(Different shape and length)

Based on the 1st year test sample evaluation results, tin whisker suppression effect was confirmed both Para-xylene and Urethane coating.

We continue the analytical evaluation to verify the effectiveness of conformal coating.

- Requirements for COTS components usage on JAXA - December 3, 2019

0 comments on Requirements for COTS components usage on JAXA