Different types of Corrosion / Contamination in Crimped Connectors

- Posted by Francisco Javier Aparicio Rebollo

- On March 14, 2019

- 0

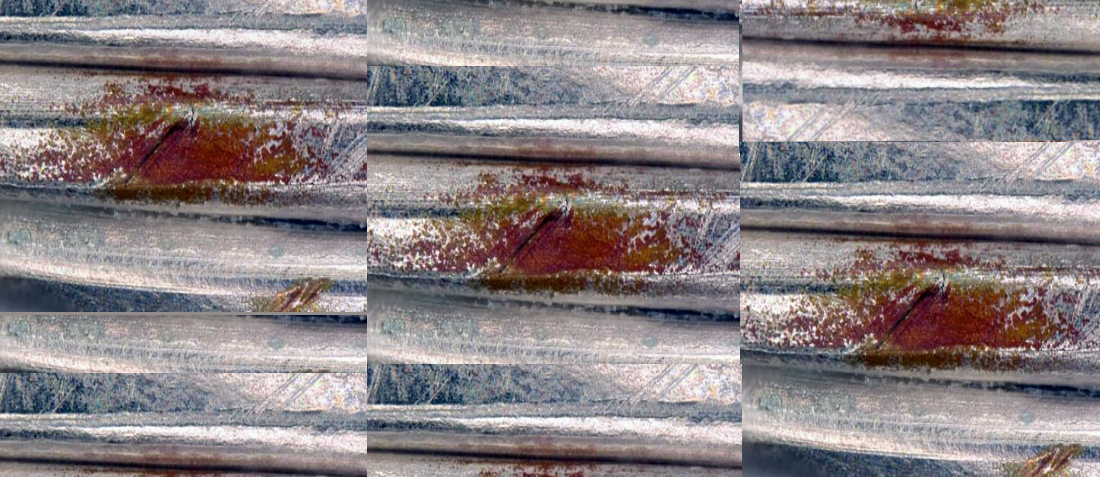

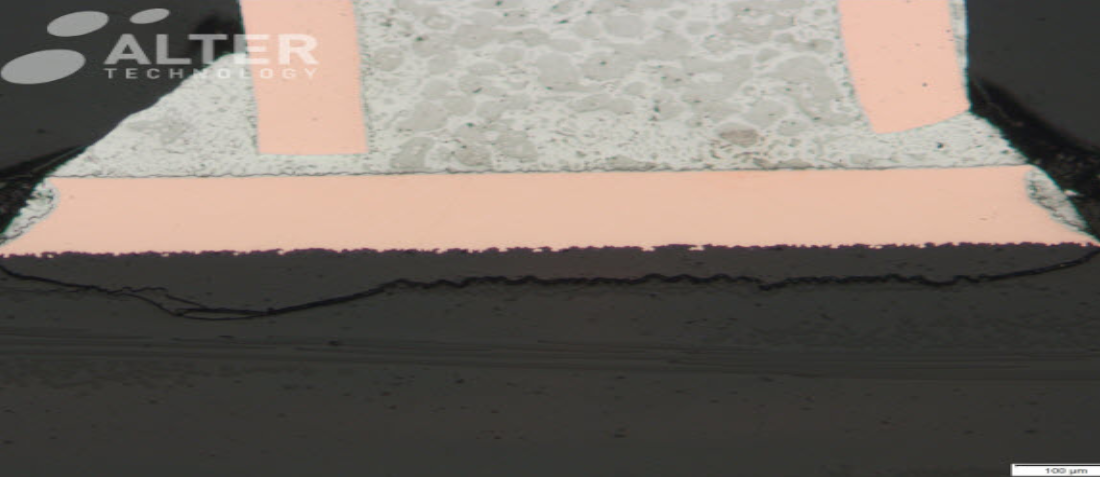

Crimped connectors are gas-tight junctions ideally protected against environmental contaminants and corrosive agents. Nonetheless inappropriate crimping and inherent connector and wire defects reduce this protection. Thus, depending of the storage atmosphere, non-conducting corrosion products can be formed, or stress corrosion cracking can be eventually induced. The former act as insolation layer that reduces the connector conductivity and both corrosion effects are identified as critical factors involved in common fails reported for electrical connectors.