The application of laser SEE testing as a new radiation effects validation and screening technique for COTS components

- Posted by Richard Sharp

- On December 3, 2019

- 0

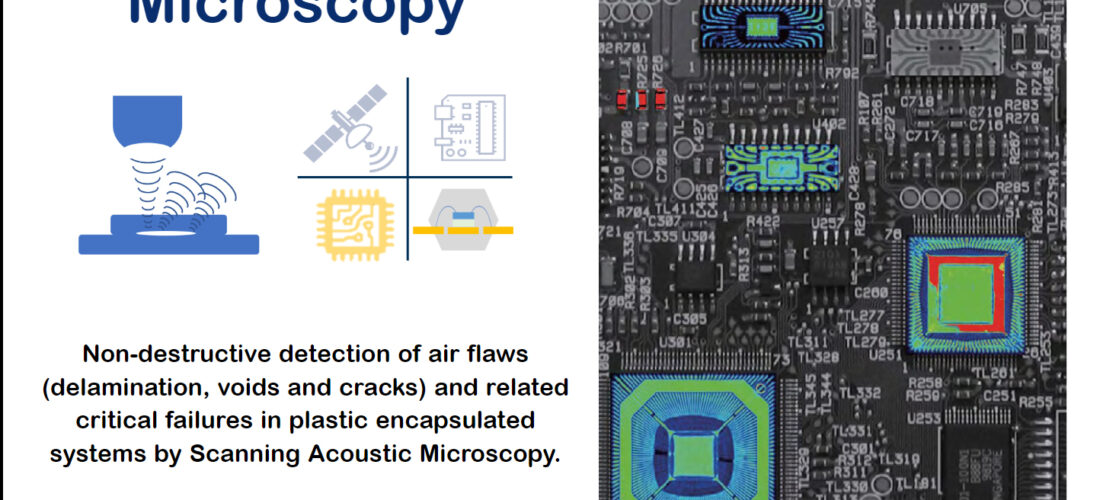

Pulsed lasers are excellent tools for the rapid screening of large numbers of parts, whether simply for latch-up or for more detailed SEE investigations. Package preparation is simpler than for heavy ion testing as no die thinning is required. Both front-side (wire-bonded devices) and back-side (flip chips) lasing can be applied. The ability to lay down very large arrays of, e.g. 10,000 laser spots under automatic control with a precision of 1 micron gives the advantages of microbeam and broad beam testing in one system. Device manufacturers can use the technique to identify sensitive areas on a die at an early stage in the design process, saving time to market and reducing costs.