Electronic Assembly Procurement

- Posted by Mario Rueda Aguilocho

- On April 1, 2022

- 0

The Electronic Manufacturing Services (EMS) market entails design and engineering, electronic assembly, electronic manufacturing, and testing services for electronic components and PCB assemblies.

Most of today’s OEMs do not have an electronic assembly process in-house, but they prefer to use Electronic Manufacturing Services (EMS) suppliers to build their products. Some of these EMSs are very large companies with locations worldwide. Electronic Manufacturing Services (EMS) are fully dedicated to the electronic assembly and test with multiple SMT lines placing millions of components and final assembly and test equipment to deliver all kinds of electronic assemblies to their customers. Most of these companies are multinationals on five continents, especially in Asia. Companies such as Flextronics, Foxconn (manufacturer of products for Apple), Jabil, etc., employ hundreds of thousands of people.

SMD components soldering

In the late 80s, most electronic assembly had SMD components on the bottom side and thru-hole parts on the top side. This board was then passed through a wave solder process to solder all parts, thru-hole, and SMD.

In the early 1990s, partly due to restrictions on the use of lead, wave soldering processes were disappearing, while SMD processes on both sides and reflow soldering were imposed. The mobile industry was taking most of the capacity of these companies and forced other types of customers to move toward the usage of smaller components if they still wanted to be in business.

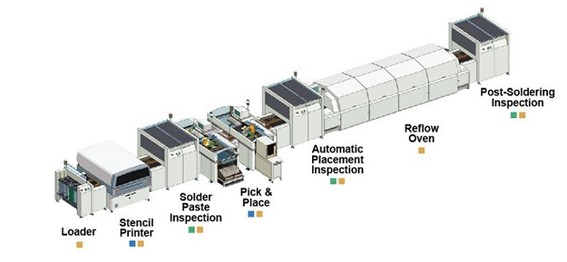

In the figure below, you can find a typical configuration of an SMD line.

Figure 1: SMD line equipment

Design for manufacturing or DFM

Nowadays, it is very common to have 3D solder paste inspection and X-ray inspection equipment as part of the process line and pick and place machines connected with the components warehouse, automatically feeding the reels to the production line.

In Spain, we have many small and mid-size EMSs. The main advantage of using these small companies is the flexibility and cost optimization due to low fixed cost structure organizations.

In this case, as designers, it is important to understand the process where the electronic boards are going to be built so that the design can be done tailored to the equipment of the process line, in other words, Design for Manufacturing (DFM).

ALTER has agreements with some of these companies to provide Turnkey projects to the final customer. Depending on the production volumes and technology needed for the assembly, we can take the production to different companies to make sure the product is built according to customer requirements, not only from a technical perspective but also from time, quality, and cost.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

Related Posts

- Electronic Assembly Procurement - April 1, 2022

- Prototyping Service - March 31, 2022

- Electronic Design: Technical design capabilities - March 31, 2022

0 comments on Electronic Assembly Procurement