Thermal Vacuum (TVAC) Test for Small Sats

- Posted by doEEEt Media Group

- On August 7, 2024

- 0

TVAC test is intended to reproduce the thermal and pressure environment that a smallsat experiences when orbiting in Low Earth Orbit (LEO).

A low Earth orbit (LEO) is, as the name suggests, an orbit that is relatively close to Earth’s surface. It is normally at an altitude of less than 1000 km but could be as low as 160 km above Earth – which is low compared to other orbits but still very far above Earth’s surface.

In LEO, the satellite experiences some 15 days/night cycles every 24h (depending on the orbit’s altitude), which induces thermal stress in all components, soldiers, and structures. A typical TVAC test has the following characteristics:

- Temperature range: -20ºC – 50ºC

- Temperature ramp <2ºC/min

- Pressure < 10-5 mbar

- Minimum 4 cycles

- 60min dwell time at temperature extremes for functional tests

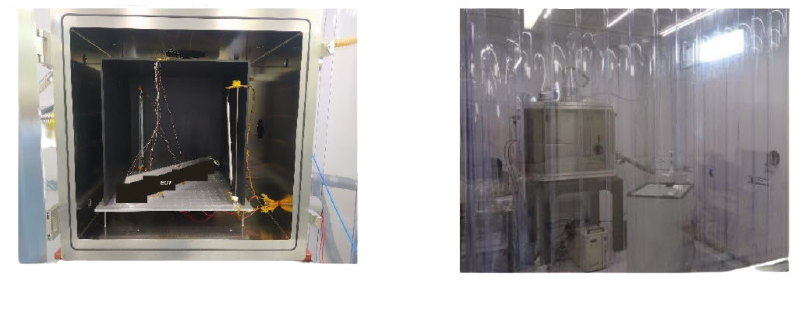

Thermal Vacuum test equipment

The Thermal Vacuum chamber is the equipment mainly used to simulate environmental space conditions. The most common Thermal Vacuum Chamber (TVC) applications are related to satellite performance tests, thermal cycle control, and testing components, subsystems, and complete satellites in a fully controlled environment. The tests can accurately reproduce the conditions of the space through the simultaneous control of pressure and temperature.

The TVAC chamber is a chamber that has 4 key characteristics:

- Can produce and maintain vacuum conditions similar to that of Space

- It can produce temperature variations. In the case of satellites, which are “hollow” structures (PCB piled in a structure), heat conduction is poor and convection non existing (vacuum), so heat transfer by radiation is the most important one. Therefore, it is important to have the TVAC chamber equipped with a shroud (cols/hot wall) and radiation heaters.

- Has feedthroughs to connect the smallsat with the ground support equipment (GSE) for functional tests.

- TVAC chambers are normally in an ISO8 or ISO5 environment to prevent contamination when extracting and inserting the EUT.

Bakeout

Typically, the launcher requires that the last stage before shipping the smallsat to him is a bakeout. Bakeout consists of heating the smallsat under vacuum to desorb all volatiles (fats, greases, organic compounds) that may be present due to handling. Typical bakeout conditions are:

- Duration: 6 to 24h

- Temperature: 60 to 100ºC

- Pressure < 10-5 mbar

Bakeout is mainly intended to protect other satellites in the fairing and avoid cross-contamination.

When the material from which the EUT is not qualified for Space, the launcher can require an outgassing measurement to be sure that the material does not emit under vacuum too much organic vapor that might deposit on third-party equipment. This measurement is simultaneous to bakeout and consists of placing a witness (clean metallic plate), which is taken to an FTIR spectrometer or a quartz microbalance (QMB) just beside the EUT to measure how much mass has desorbed and ensure its cleanliness.

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Thermal Vacuum (TVAC) Test for Small Sats