The requirements about the neccesary level of SCREENING to apply on a lot of EEE components, are stablished in documents like ECSS-Q-ST-60C, ECSS-Q-ST-60-13C for commercial EEE components… and/or at project level.

The requirement about WHAT to do and HOW are included in documents like Generic Specificacionts, MIL-STD Test Methods, NASA EEE-INST-002, NASA PEM-INST-001…

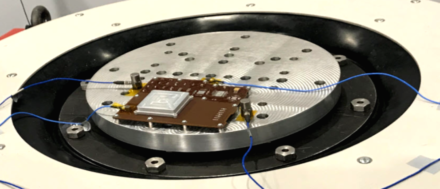

ALTER TECHNOLOGY has an accumulated experience on EEE parts lot screening; specializing in designing tests and screening procedures for electronic components used in the aerospace, defense, and industrial electronics industries.

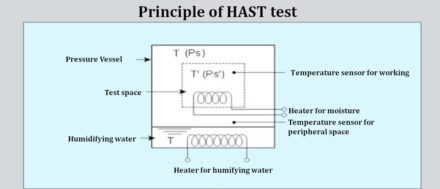

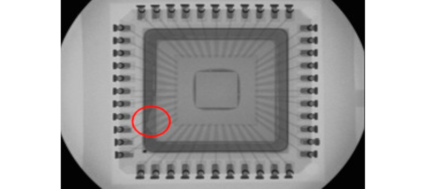

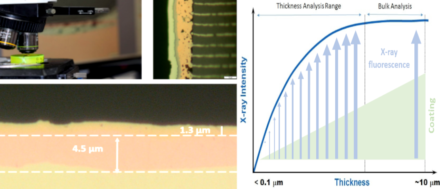

Tests, inspections or combination thereof, imposed on 100% of parts to remove unsatisfactory items or those likely to exhibit early failures.

Using stress testing, defects are weeded out in a product where the root causes cannot be eliminated. Removing all the defective parts (infant mortality) brings the lot to the constant failure rate (working life) phase.

The screening does not increase the reliability of the components but removes those showing weakness or defects.

European and international space programs use parts which are typically screened according to ESCC and MIL specifications.