Lot Acceptance Test (LAT)

- Posted by Alejandro López Moya

- On June 28, 2021

- 0

A Lot Acceptance Test (LAT) is a reduced set of Qualification tests over components or equipment, required to accept a specific manufacturing lot for its use. A LAT sequence allows customers to have a complete traceability of the components they are going to use in their application, starting from the wafer used during manufacturing. Previously to LAT, manufacturers must have carried out a Qualification process where components/equipment are submitted to a complete set of tests.

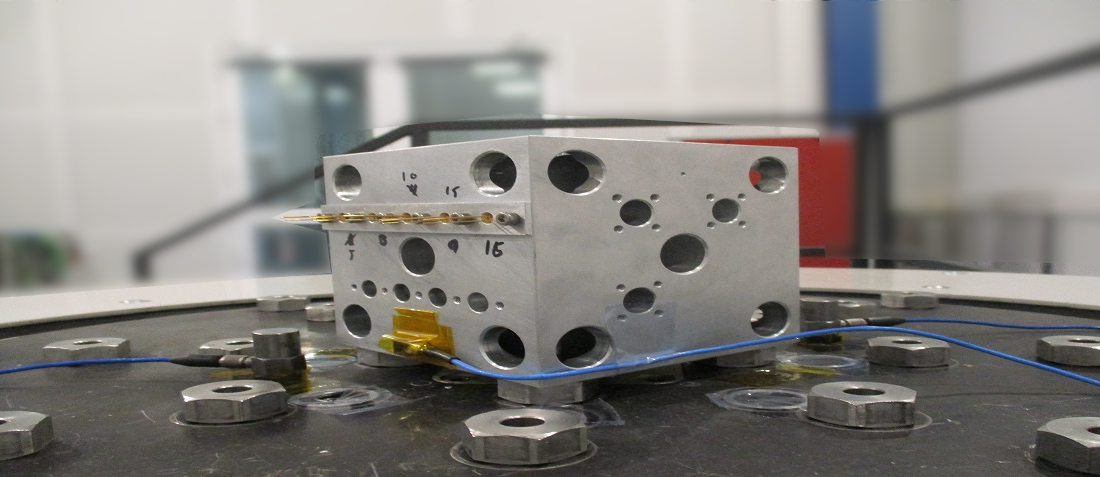

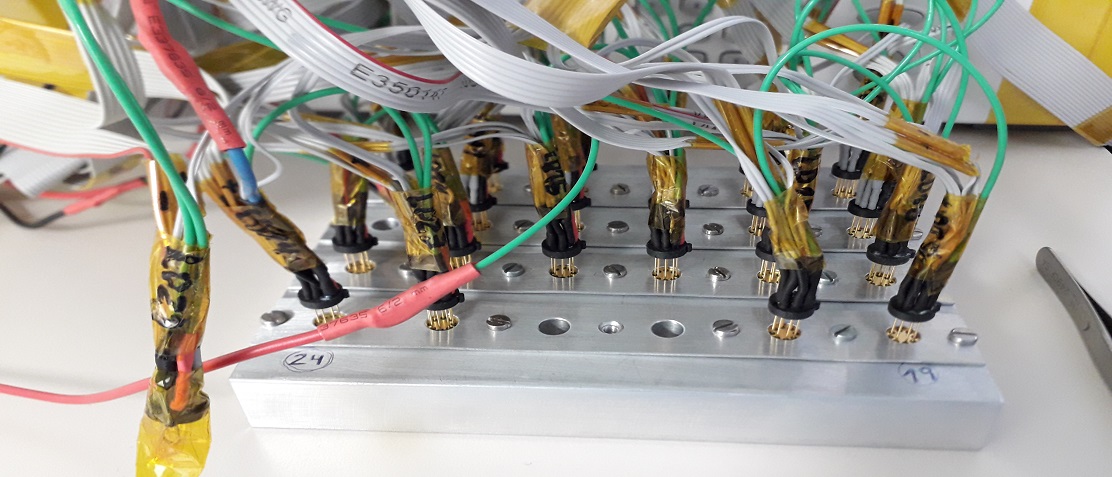

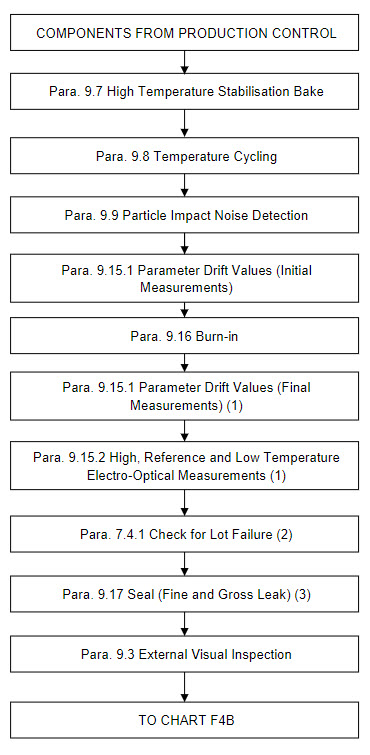

Before starting with LAT, a Screening test sequence is carried out over the lot under test to detect potential failures, and to assure that components/equipment specifications are inside the ones provided by the manufacturer. One of the most important tests of the Screening sequence is the Burn-in test.

In this test, components or equipment are submitted to work at elevated temperatures for several hours. This test permits to detect failures in components like infant mortality, allowing to remove bad samples from the lot evaluated. Normally, a functional characterization is done before and after Burn-in, and in case of parameter drifts higher than expected, the whole lot can be rejected before start with LAT.

In the case of components, at the end of the Screening test sequence, the best samples from the lot are selected and reserved for the final application (i.e., Flight models for space applications). In contrast, the rest of the components continue with LAT sequence.

Figure 1- Screening test sequence for Laser Diodes according to ESCC23202

GET IN TOUCH TODAY!

Do you have questions? Contact us!

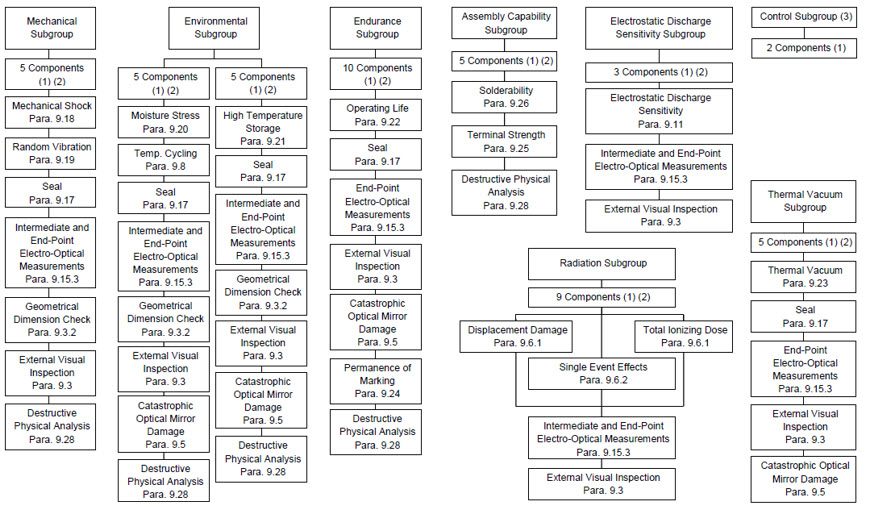

Every family of components has its own standard for LAT sequence. This sequence normally includes Mechanical tests, like vibration and shocks, to ESD tests, Environmental tests, Endurance tests, Radiation tests (Heavy ions, Gamma,…), Thermal vacuum tests, Assembly test, and so on… This set of tests could be modified depending on the final application of the component/equipment.

Samples that continue with LAT sequence are split into different groups and assigned to the different blocks of tests inside a LAT. An example of LAT sequence for Laser Diodes, according to ESCC23202, is shown below:

One of the most important tests inside a LAT sequence for components used in space applications is the Radiation test. How a component behaves against different kinds of radiation found in space depends on quite a lot on wafers manufacturing processes. Due to this reason, the same components from different lots could have different tolerance to radiation.

One more test to highlight inside LAT sequence is the Endurance test. In this test, components are submitted to work during a long period of time (i.e. 1000, 2000 hours…), and sometimes while in vacuum or extreme temperature conditions. In space components, this test is critical because it is going to show if components are prepared to support mission lifetime.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- IR SOURCES THERMAL VACUUM CYCLING CHARACTERIZATION - February 11, 2022

- Lasers Endurance Characterization in Vacuum Conditions – Test Setup - January 25, 2022

- Calibration Sources in Vacuum Conditions - January 13, 2022

0 comments on Lot Acceptance Test (LAT)