Engineering and Testing of Hi Rel Electronic Components

- Posted by David Ramirez - Cruzado

- On July 3, 2010

- 0

Engineering And Testing

High reliability electronic components, Space electronic components.

Engineering and Testing, What Do We Offer to Our Customers?

-

-

- Comprehensive experience in the high-reliability electronic components market

- Parts engineering expertise in product selection and design-in support

- Technological evaluation and technology assessment

- Manufacturer survey

- Trade-off analysis

- Testing capabilities for performing any kind of screening for high-reliability applications

- Direct contact between suppliers and customers, simplifying the product selection process, access to technical information and determining the proper procurement approach

-

All these services are done between our Engineering and Testing of Hi-Rel Electronic Components at our laboratories.

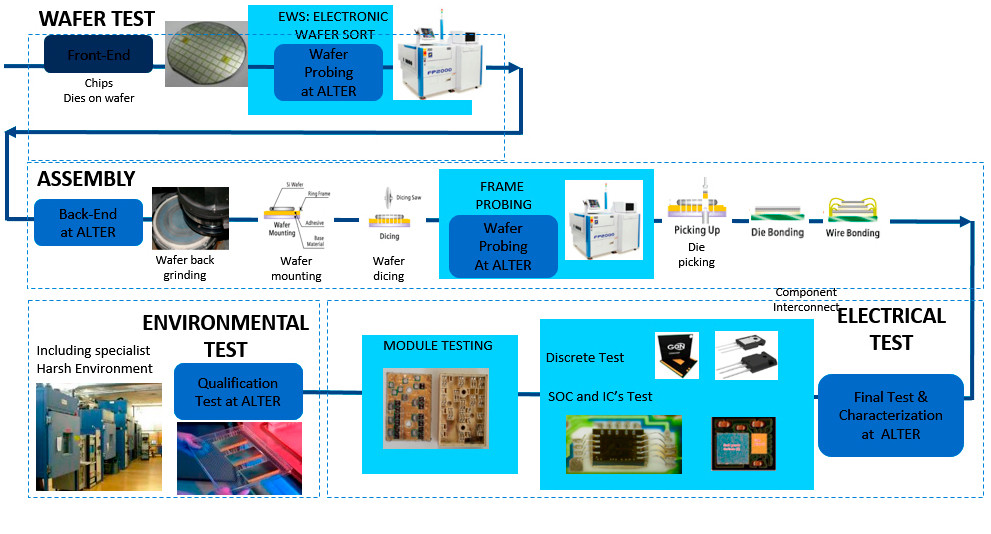

Assembly & Test Capability

Main Activities and Processes between Engineering and Testing

-

-

- Screening, plan preparation and engineering support

- Initial and Final Customer Source Inspections (Pre-cap and Buy-Off inspections worldwide)

- DPA (Destructive Physical Analysis)

- LAT (Lot Acceptance Test), QCI (Qualification Conformance Inspection)

- Constructional analysis, reverse engineering

- Evaluation analysis of the suitability of commercial parts for space use

- Failure analysis investigation

- Authenticity test, counterfeit investigation

- Thermal characterization

- Repacking

- Element evaluation (of hybrid add-on parts)

- Special conditions storage (hot & cold, dry nitrogen atmosphere, etc.)

- Managing, inspection and storage of dice

- Parts engineering and logistics

-

Hi-Rel Electronics Components

Quality of the components is a key factor

The EEE (Electrical, Electronic, and Electromechanical) components are the basic elements of any electronic system which are the fundamental building blocks that determine the final equipment performance, in terms of the electrical performance, mechanical strength, and ability to meet the environmental stresses they will encounter in service.

Highly skilled teams, deliver innovative solutions for counterfeit avoidance, failure analysis, FPGA programming, component screening, radiation, test and optical component evaluation and qualification, to verify the suitability of the selected

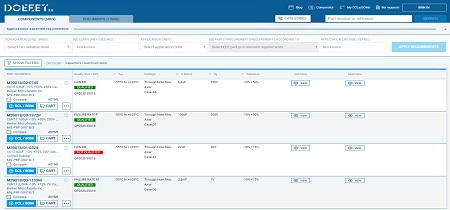

Click to access doEEEt, find 17 million of HI-REL parts references.

GET IN TOUCH TODAY!

Have questions? Contact us

- Internal Visual Inspection of Hi-Rel EEE Parts - November 6, 2020

- What is an External Visual Inspection? - May 21, 2020

- Identifying Leakage Pathway with a Penetrant Dye Gross Leak Test - March 13, 2019

0 comments on Engineering and Testing of Hi Rel Electronic Components