Experience on SEE testing EEE parts

- Posted by doEEEt Media Group

- On February 19, 2020

- 0

Experience on SEE testing EEE parts (Memories, RF Power devices…)

- Many basic testers available which offer the capability to carry out a test in a rather short delay (a few weeks) at a relatively low cost.

- Capability to develop on-demand test setup for complex devices (μP High-frequency devices, RF fixtures etc…) higher cost driven by the test preparation effort.

- Access to many facilities, the selection is based on more than 15 years of experience.

- In house device opening capability, especially for plastic packages more and more difficult.

- Good electronics skills are mandatory for test setup development as well as a good knowledge of the tested device.

AIRBUS DS Test Activity Overview

- More than 600 tests since 2003.

- Mainly dedicated to provide SEE behaviour of EEE devices used by any ADS project.

- Fully integrated within the procurment process at early level, traceability (man lot, factory etc…) avoid a huge number of tests.

- Some internal R&D activities as well as some funded by ESA, CNES and DLR.

- Support on request to external customers (mainly on ADS related projects).

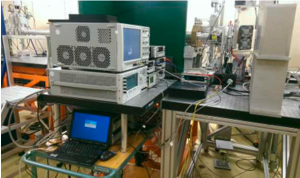

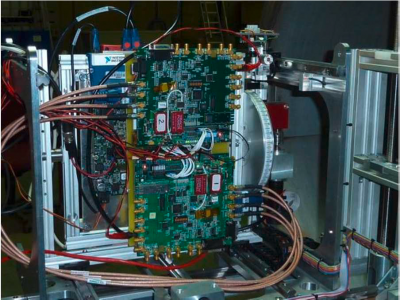

Test benches

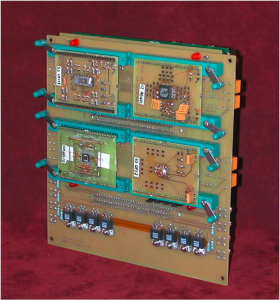

Generic test benches used for more than 90% of devices

- 4 test slots

- Board compliant with all facilities.

- Many remotely programmed analog and digital I/O

- High speed digitizers for SET

- Ability to test SEU, SET and SEL separately or at the same time depending on the device

- Ability to test Opamps, comparators, voltage ref and regulator, DAC, ADC and the most current digital circuits (line buffer, latches etc…)

- Ease of daughter board design (a few days)

- Capability to change quickly test conditions during test

- Autotest to check device and tester good healt

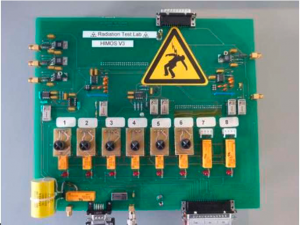

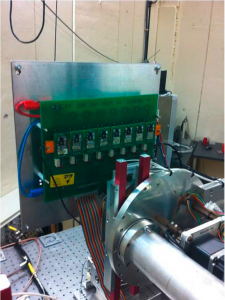

- 8 test slots

- Can hold P or N channel up to 600V Vds and +/-100V Vgs

- On line measurement of Igss (10pA to 100mA) and Idss

- SEB detection and Drain charge collection integrated acquisitions

- Integrated VGSth measurement for N channel (P to be added)

- Integrated PIGST capability

- Fully Remote controlled operation

- Integrated autotest to check device connection and tester integrity before irradiation ( a not connected device is seen unsensitive )

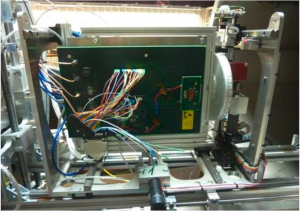

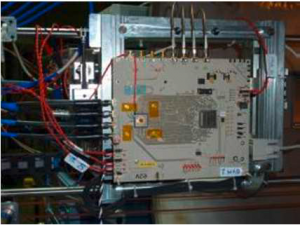

- 40 MHz asynchronous mode & 20 MHz synchronous DDR mode

- 2 adjustable protected supplies (SEL) with on line voltage and current monitoring

- Embedded Processor under Linux RT and FPGA

- Remote controlled operation through single ethernet link

- Integrated hard drive for high speed data recording (many Gbytes of data during test)

- User defined test sequence up to 2000 cmd/s

One shot test benches

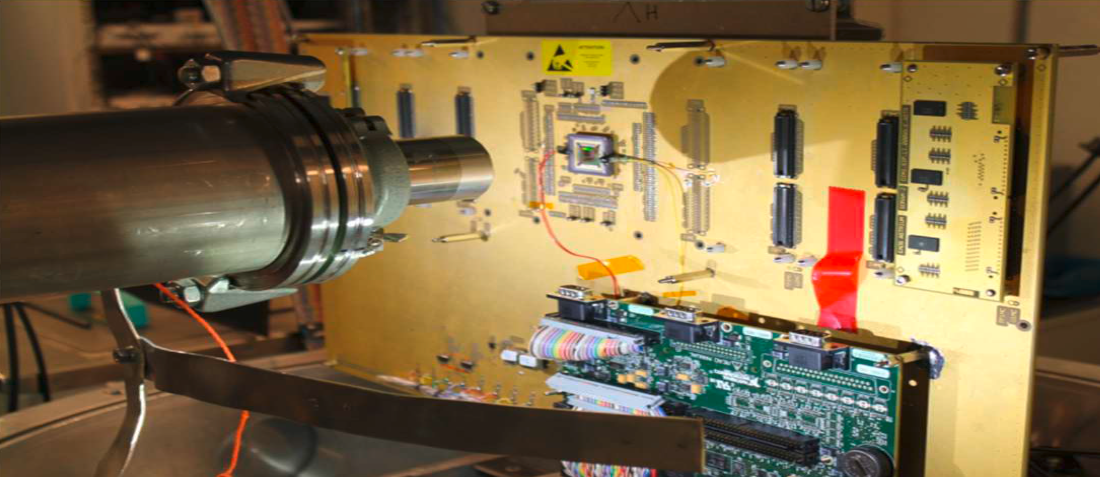

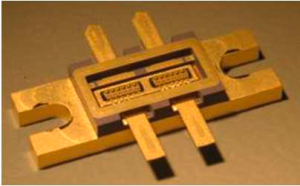

RF SEE Testing

- Complex RF Test Setup

- High RF Power handling capability

- Peltier Cooling Unit

- Remote control capability

Download or read the full report here

Latest posts by doEEEt Media Group (see all)

- Space-Grade components available for immediate delivery - April 10, 2025

- Exclusive stock on doEEEt: How to access and request - April 10, 2025

- Managing EEE components for LEO and lower cost space missions - December 17, 2024

0 comments on Experience on SEE testing EEE parts