CHARACTERIZATION OF STRAIN GAGES

- Posted by Juan Barbero

- On February 16, 2022

- 0

Custom setups for testing Strain Gages in extreme temperature and vacuum conditions

The Strain Gages are used to measure the deformation of materials. These devices are widely used when the deformation of a structure is relevant such as the wings of a plane or the structure of telescopes or rockets. The necessity of testing these strain gages at a wide temperature range leads to the necessity of coupling force-deformation equipment to climatic chambers.

This document describes how ALTER has done this to allow testing Strain Gages from -190ºC to more than 200ºC. The use of Strain Gages in space leads to the necessity of testing them in thermal vacuum conditions. A description of the setup developed by ALTER to do a life test with periodic application of strain in vacuum at a controllable temperature is also described.

1. INTRODUCTION

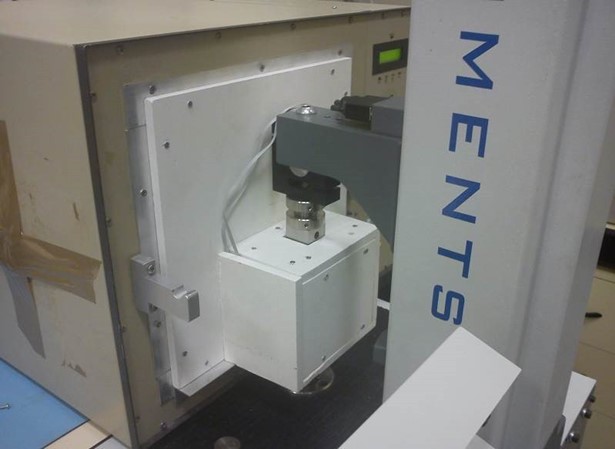

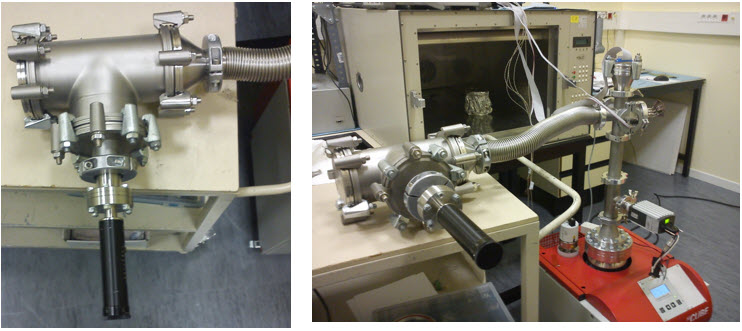

The main challenge for the testing of the strain gages for a wide temperature and vacuum it to control the temperature of the sample while the strain/force tests were being applied. ALTER has developed for this purpose a custom combination of a small climatic chamber and a force tester by designing and manufacturing a door adaptation that permits to have the strain gages under tests glued on the aluminum supports and the part of the metal blocks needed to fix them in the climatic chamber while keeping the force meter out. A setup with a small vacuum chamber with a coupled linear move feedthrough has been prepared and used for the vacuum tests.

2. STRAIN GAGE TEMPERATURE SETUP

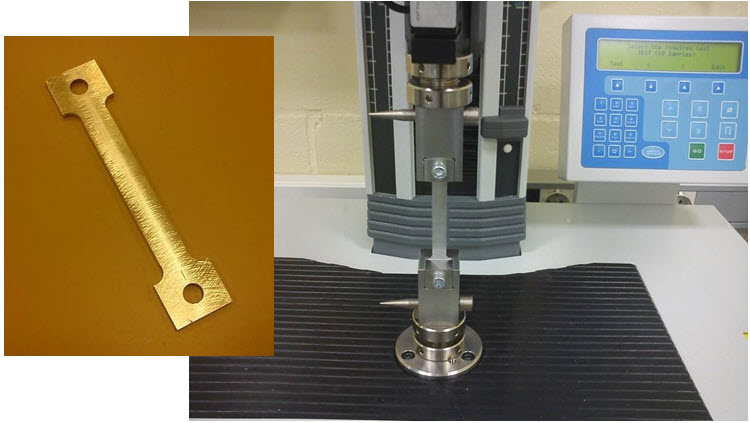

The following picture shows the setup prepared for the strain tests. The dimensions of the aluminum piece are 2.5mm x 10mm x 100mm.

The following pictures show the setup prepared for the temperature characterization of Strain Gages:

A control thermocouple (T-type) is placed in contact with the metal support. This thermocouple is used to adjust the temperature of the chamber to the required value. The chamber can cool down with liquid nitrogen till -190ºC and to more than 200ºC. Note that the cables used to monitor the Strain Gages need to be selected for the temperature range of the tests.

3. 0STRAIN GAGE vacuum SETUP

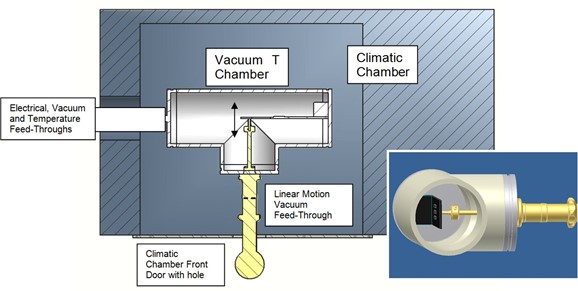

The following drawing shows a scheme of the setup proposed for testing Strain Gages in a vacuum at a controllable temperature with the possibility of applying a deformation to the samples.

The T-Shaped vacuum chamber is closed using metallic sealing to allow a wide temperature range to be used. All the electrical connections, including the thermocouples, go inside the flexible tube to appropriated electrical feed- thoughts that are kept outside the climatic chamber where the vacuum chamber is placed.

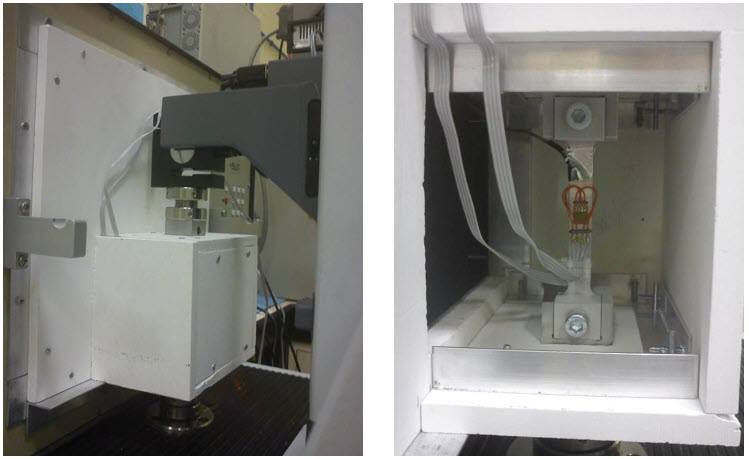

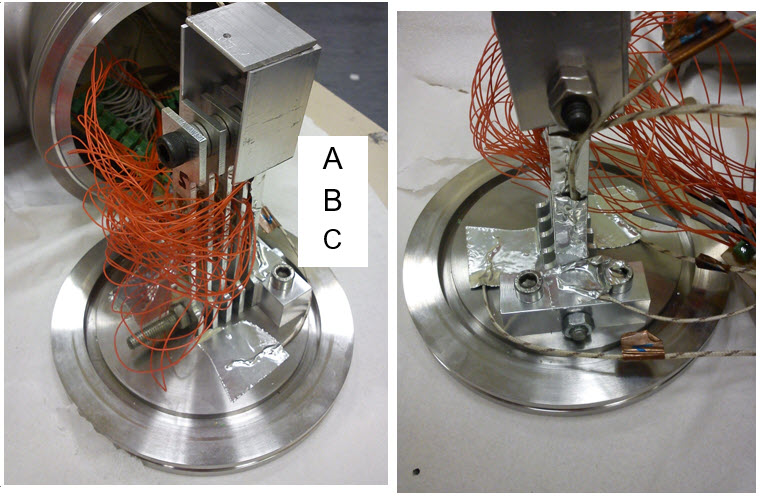

The following pictures show the assembly of the 15 strain gages in this setup for a life test including the placement of thermocouples to control and monitor the temperature inside the chamber. As shown, the samples are placed with the samples far from the fixing plate.

3.1 Example of results

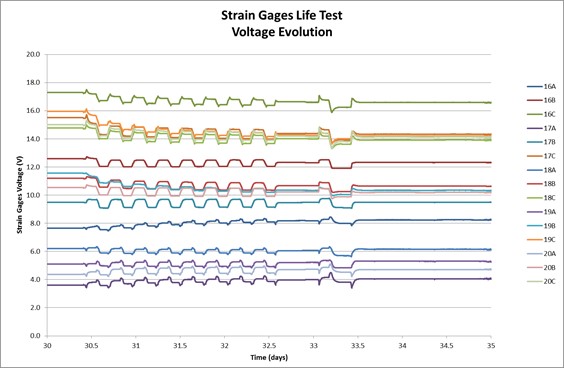

The following pictures show an example of the evolution of the voltage measured at the Strain Gages during the days when the thermal cycling and the vacuum were applied.

4. Conclusion

ALTER has developed custom setups for testing Strain Gages in extreme temperature and vacuum conditions that allow monitoring of their behavior. These setups have been used for testing Strain Gages for space applications and they could be adapted to fulfill other requirements from other customers.

Contact us

ALTER TECHNOLOGY LAB EXPERIENCE

- CHARACTERIZATION OF STRAIN GAGES - February 16, 2022

- JUICE – JUpiter ICy Moons Explorer - February 14, 2022

- Mars Curiosity Rover: Characterization of photodiodes at cryogenic temperatures - February 14, 2022

0 comments on CHARACTERIZATION OF STRAIN GAGES