JUICE – JUpiter ICy Moons Explorer

- Posted by Juan Barbero

- On February 14, 2022

- 0

Monitoring of JUpiter ICy Moons Explorer JUICE Optical Fibers During Thermal Cycles Keeping the Optical Connectors at Different Stable Cryogenic Temperatures in 3-Chambers Setup

Introduction

In May 2022, JUICE (JUpiter ICy moons Explorer) will begin a 7.6-year cruise to Jupiter to spend three and a half years in the Jovian system.

The JUpiter ICy Moons Explorer (JUICE) is a spacecraft designed by Airbus Defence and Space for the European Space Agency (ESA) mission to fly the Jovian system. It is the first Large-class mission in ESA’s Cosmic Vision 2015– 2025 program. They are planned for launch in 2022 and arrival at Jupiter in 2030.

Its main mission will be to explore the vast planet’s three largest icy moons, Europa, Ganymede, and Callist, in the hope of determining whether life is possible on these dwarf planets. One of the instruments that JUICE will carry is a Magnetometer that will be deployed with a 10.5 boom to keep it clear of the spacecraft’s main body, allowing to make measurements clear of any magnetic interference. Its goal is to measure Jupiter’s magnetic field, its interaction with the internal magnetic field of Ganymede, and to study subsurface oceans of the icy moons.

The data from and to the magnetometer will be sent using optical fibres traveling from the relatively protected ambient of the ship’s core to the boom. This structure will lead to a unique thermal profile of the fibers and optical connectors. A complex test with three coupled climatic chambers was proposed to thermally cycle the fibers and the connectors (FC/APC). Each pair of these connectors exposed during the mission will be significantly different. The modeling of such a setup had never been verified, and it was decided to test with the accurate expected temperature profile (including some margins). The rate and the temperature of each chamber were controlled independently to allow the simultaneous stabilization of the three chambers.

Test setup

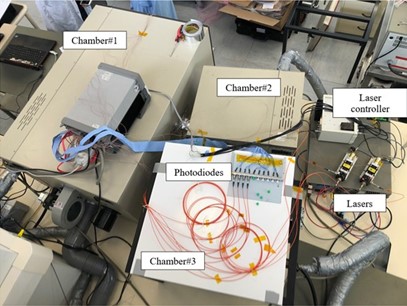

Several geometries for the placement of the samples were considered. The main limitations were related to the position of the holes to pass the fibres. Each chamber has a lateral hole generally used for access, and some of the doors were also adapted to allow connecting them. The same stable light source used by IWF/TUG for the magnetometer was used during the test. The optical power of each of the paths was monitored with independent photodiodes read with a switching matrix. The following picture shows a top view of the 3-chambers configuration used during the thermal cycling test.

JUpiter ICy Moons Explorer (JUICE): Test Results

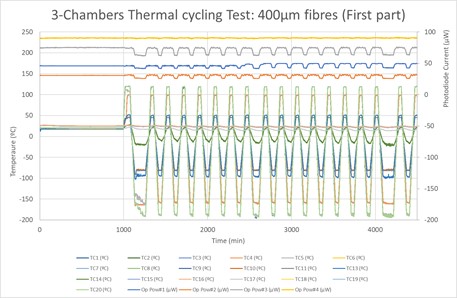

400µm MM Fibres test

The following picture shows an initial detail of the first cycles monitored for the 400µm fibres:

- The first cycle had several steps during the cooling of chamber#1.

- Cycle #8 and particularly cycle #16 have longer low-temperature stabilizations. This was related to variations of the monitored temperature that fell out of the stabilization criteria leading to the longer time needed to fulfill it.

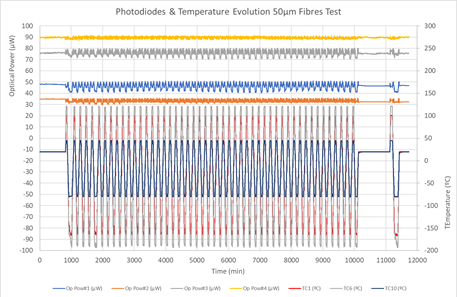

50µm MM Fibres test

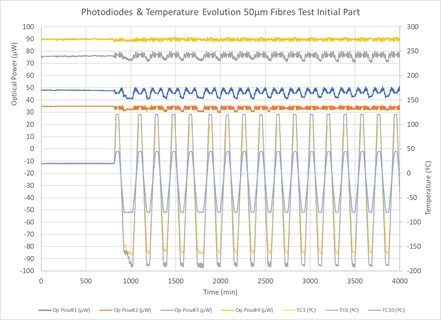

The following picture shows the complete monitored data during the 50µm MM fibres test.

The 4 top graphs are the photodiode current monitored. The yellow line is the reference path.

The following picture shows a detail of the initial cycles.

Numerical Results

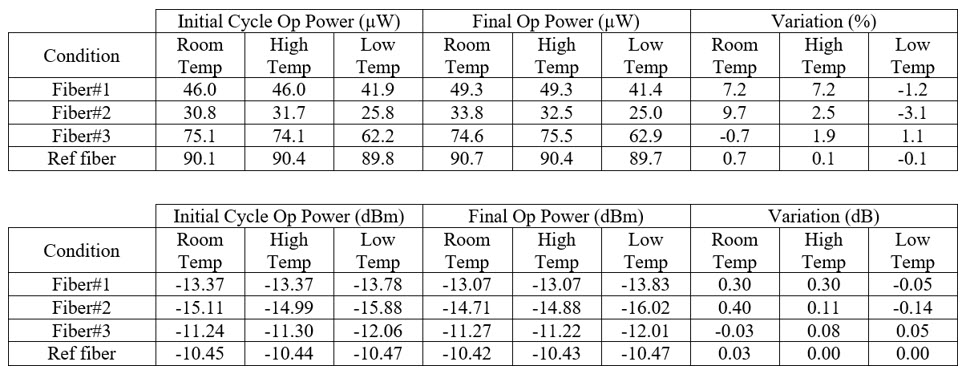

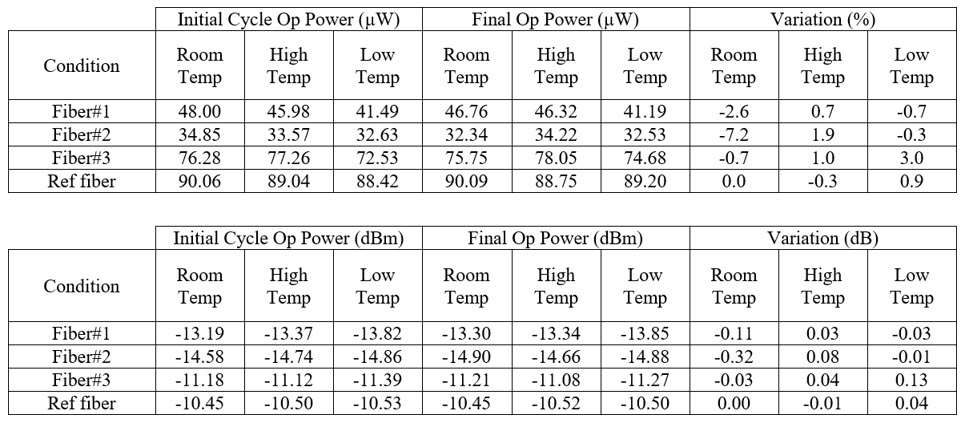

A numerical comparison of the data at stabilized temperatures is given in the following tables:

The following tables present the results for the 400µm fibres:

The following tables present the results for the 50µm fibres:

Conclusion

A complex thermal cycling test was necessary to test the fibers that are going to be used in the real scenario for the magnetometer of the JUICE Mission. The analysis of the triple thermal test results of both types of fibers shows no measurable degradation. The preparation of the test was complex, but it allowed the validation of the test setup in an equivalent thermal scenario as expected during the mission.

The actual test setup, including the handling of the fibers and the connectorization was done by the staff of the Space Research Institute of the Austrian Academy of Sciences (IWF) and of the Technical University of Graz at ALTER premises.

GET IN TOUCH TODAY!

Have questions? Contact us

About Thermal Cycling test

The objective of thermal cycling testing is to determine the ability of parts and solder interconnects to resist extraordinarily high and low temperatures and their ability to endure cyclical exposures to extreme temperatures.

Permanent changes to the electrical or physical characteristics of the devices under test that compromise their long or short-term reliability can result from the effect of thermal-induced mechanical stresses.

Thermal mismatch of materials can cause, among other things, solder joint cracking, hermetic seal failures, and damage to leads and markings.

Cycling rates and other test conditions for components, boards, solder interconnects, and tin whiskers evaluation can be specified. Operating and storage temperature limits to be considered are those specified by the manufacturer.

- CHARACTERIZATION OF STRAIN GAGES - February 16, 2022

- JUICE – JUpiter ICy Moons Explorer - February 14, 2022

- Mars Curiosity Rover: Characterization of photodiodes at cryogenic temperatures - February 14, 2022

0 comments on JUICE – JUpiter ICy Moons Explorer