CPPA contractual framework

- Posted by Alvaro Real

- On January 4, 2021

- 0

What is the CPPA?

The CPPA (Coordinated Parts Procurement Agency) is responsible for the engineering, testing and procurement of the EEE parts of a certain space mission. This structure has a dedicated contractual framework designed for the Users´ benefits

Over the last 30 years, Alter Technology has gathered an extensive experience acting as a CPPA for most relevant ESA class 1 missions such as Meteosat, Euclid, JUICE and most recently PLATO. The CPPA is an investment performed by ESA to guarantee a successful procurement and it has a contractual framework that defines highly advantageous conditions in terms of cost for the Users.

Cost drivers of the CPPA

EEE components are a key contributor and driver to the cost of the system. The total ownership cost of those EEE components remains a non-negligible part of the cost of the system. That fact is due to the price of space EEE components cost remains high as well as the effort in engineering, quality and logistic which is required to procure those EEE is significant. For this reason, A careful study needs to be carried out from the very beginning to ensure the project will perform within an agreed budget and schedule limits.

The CPPA establishes a clear cost breakdown between what is charged to the Users and which concepts are covered by ESA. However, prior to go deeper into the CPPA foundations, it is highly recommended to have a clear picture of the 4 top-level cost procurement concepts. Manpower refers to the cost related to people allocated in the program (engineers, quality, testing etc..). In addition to that, the analysis needs to envisage the parts Manufacturers’ costs which are divided in Recurring Vendor Costs (RVC) and non-Recurring Costs (NRVC).

Then, it also required to consider the testing cost understood as an additional cost for testing not done at manufacturers but required by the project to meet the quality requirement. Finally, quality issues lead to cost increases regarding NRBs, extra testing, or new procurements. The CPPA provides relevant savings on all these 4 top-level cost concepts.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

Advantages for the CPPA Users

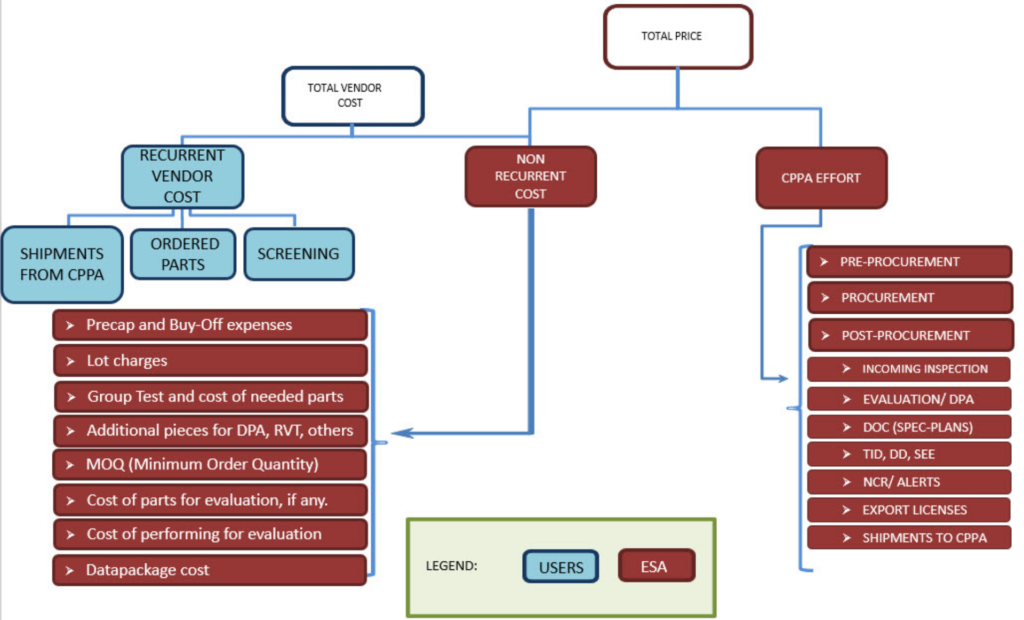

The cost distribution can be clearly identified the below figure through the light blue legend for costs charged on the Users and the dark red legend for those covered by ESA. At first glance, it is clear how advantageous the CPPA is for all economic operators that supply through it. Users only need to cover what is known as RVC whereas the CPPA contract covers all the other concepts. This is the classic scheme since there could be any programs where conditions could differ.

Nevertheless, what is considered RVC in the CPPA contract and what is exactly the saving for the Users? RVC is the cost for every single component multiplied by the quantity of flight units. CPPA will take care of procurement for FM accepted parts for all Users. The quality applicable for FM for EEE parts will be iaw. PA (Product Assurance) requirements. The Users will receive the quantity they ordered regardless of the MOQ (Minimum Order Quantity) applicable to the parts. MOQ for EM & EQM parts are not included on the CPPA contract and need to be covered by the Users.

For instance, in the last CPPA contract applicable for PLATO Program, Users will also cover half of the shipment from the CPPA to their facilities since the shipment from manufacturers´ to CPPA is covered by CPPA contract. In addition, Users are covering the screening cost for COTS procured in the program for validating the FM parts whereas ESA covers the evaluation/qualification cost.

ESA’s Contribution

The Users´ cost obligations have described it. On the other hand, ESA provides a great contribution in terms of cost, divided into 2 main fields: the non-recurrent cost (NRC) and CPPA effort or surcharge. The non-recurrent cost mainly occurs in the procurement phase, whereas the surcharge plays a role during the 3 phases of the CPPA activity: pre-procurement, procurement, and post-procurement.

The NRC is the total amount obtained when adding the total NRVC and the total NRAC (Non-Recurring Agent Cost). NRVC are costs which are charged by manufacturers for covering the requirement in the purchase order (through additional tests, such as LAT/ group test, lot charges, test samples, buy-off assistance, precap assistance, minimum order quantity) and to establish lot documentation (data package, single lot date code feeCPPA activities included in the NRAC and not covered by the Surcharge are the cost of performing evaluation/ qualification test, TNID test, heavy ions test, among others.

On the other hand, the surcharge is the cost charged by the CPPA for the work and test/laboratory analysis performed under the contract to coordinate the procurement of EEE Parts between all users to exclude the activities considered under NRAC. In addition to that, surcharge also covers tasks related to engineering support, quality issues control, export control, and project management.

There are relevant aspects of the surcharge concept. Data Pack Review and Incoming Inspections are performed on all FM parts procured. When applicable other tests are performed (i.e. DPA, TID, PRECAP and BUY OFF inspections, etc.) by CPPA. Moreover, shipment preparation for all FM parts, including the CPPA CoC and packing list, is also included under the surcharge.

Additional Activities covered by the CPPA

Additional aspects are DCL analysis and documentation preparation. As parts of the engineering tasks, CPPA reviews users list of components providing applicable comments, including alternatives and preferred parts for the program’s PA requirements. Furthermore, CPPA covers the PADs generation and approval for all FM parts and the issuing for all test plans discussed in the frame of procurement.

Quality issues management is also a key cost driver who is covered by the surcharge´s umbrella. One person shall be assigned as quality responsible for every project. Different tasks request an important amount of time and technical expertise, emphasising the discussion with manufacturers regarding failures, NCRs and NRBs assistance and discussion.

Export control also has a great impact on procurement. Parts subject to USA ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulation) restrictions (export licenses) are considered as critical. They require specific management on a case by case basis. CPPA prepares the applicable documentation as per the legislation. Delays in export control could lead to delays within the parts procurement. That´s why it is highly recommended to count on staff members prepared for meeting export control requirements.

Last but not less, procurement of EEE parts needs a proper follow-up to assure project lead-times will be respected and anticipate delays. Lead-times for EEE from manufacturers´ can vary from a few weeks to almost a year, and not all of them send periodic backlogs with estimated delivery dates. CPPA assigns personnel to this task during the whole procurement process as relevant aspect with the surcharge.

- CPPA contractual framework - January 4, 2021

- PLAnetary Transits and Oscillations of stars PLATO - October 9, 2020

- Benefits of a coordinated procurement agency for EEE parts - August 10, 2020

0 comments on CPPA contractual framework