Rad-hard parts available in the market

- Posted by Javier Alejandro de la Ossa Fernández

- On November 11, 2020

- 0

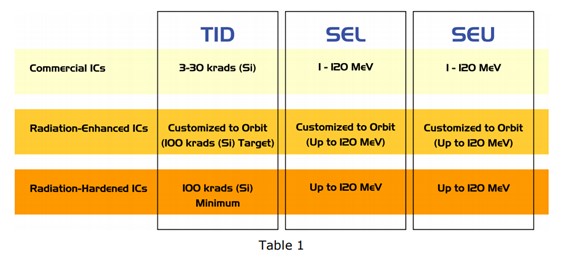

Traditionally, “bulletproof” rad-hard parts are defined as capable of withstanding over 100 krad(Si) of TID and are SEL and SEU immune up to 120 MeV. Beyond these minimum thresholds, definitions of TID, SEL, and SEU vary from manufacturer to manufacturer. Where one manufacturer considers a part of being rad-hard if it has a TID threshold of 300 krad(Si), another company may market their part as rad-hard if it only meets 100 krad(Si).

Commercial parts will have TID ranges between 3-30 krad(Si)and SEL and SEU ranges between 1-120 MeV. Of course, commercial parts are not designed with radiation performance in mind. Nevertheless, a few commercial ICs have, in fact, exhibited acceptable radiation-hardened characteristics.

A few new manufacturers are seeking to take advantage of these commercial diamonds in the rough. This growing group utilizes select commercial silicon to produce space worthy devices. In fact, there are several commercially based space devices available that have either been tested for and/or modified for use in space. Their manufacturers include Data Device Corporation and UTMC.

The technologies and approaches to space-ready a commercial device vary, but there are three general methods used to enhanced total dose protection. Data Device Corporation encapsulates already radiation-tolerant commercial parts in a patented package technology, called RAD-PAK®. This package incorporates a scientifically calculated amount of shielding directly into the electronic package.

Another approach, which is used by UTMC in a property process, involves the refabrication of a commercial semiconductor on a radiation-tolerant process line. A third method involves building mitigation technologies into a packaged device. For example, Data Device Corporation offers a Latch-Up Protection circuit that is designed to detect the current increases associated with latch-up at the device level.

On a continuum measuring usability in space, radiation enhanced ICs lie between commercial and traditional radiation-hardened parts. A speciality space counterpart, but it can provide enough features that a designer will often consider its usability, given its inherent cost savings and technical sophistication.

Strategies for building satellite systems

In the 15th century, Leonardo Da Vinci wrote, “Design is inhibited by freedom and flourishes in constraint”. This axiom holds true today. Designers in days gone by had to meet a very strict set of radiation requirements. All parts selected for a mission, be it military or scientific, had to be bulletproof. Period.

But thanks to the advent of commercially based technologies and to the commercialization of space, designers now have four strategies for building satellites. With the first strategy, a designer can choose to engineer a system using only traditional rad-hard parts. While it provides the best protection from radiation, this approach tends to be the costliest. It is typically reserved for highly sensitive military applications where absolute survivability is an integral part of the satellite’s mission.

With the second strategy, a designer may choose to use only radiation-enhanced semiconductors. While this strategy provides a significant cost saving, there is no ideal commercially based solution for every component inside a satellite.

The third option for designers is to use inherently radiation tolerant commercial semiconductors. This strategy provides a significant cost saving, there is no ideal commercially based solution for every component inside a satellite.

The third option for designers is to use inherently radiation tolerant commercial semiconductors. This strategy saves more money than using radiation-enhanced semiconductors, but the responsibility to test and identify the parts lies solely with the satellite designer (due to the small relative size of the satellite market, no major commercial IC manufacturer appears to have a vested interest in investigating the radiation tolerance level of its parts).

The final approach to component selection is the use of commercial semiconductors without any regard for radiation tolerance whatsoever. This method is without a doubt the least expensive but is also the one fraught with the most unknowns – and these unknowns can be disastrous to mission-critical space applications.

Since budgets are a constraint on all system designs, a combination of the first three strategies is generally used. Traditional rad-hard components are designed into mission-critical applications and radiation enhanced or radiation tolerant semiconductors without regard for radiation tolerance is typically reserved for on-board experiments or for satellites that are themselves considered to be experiments.

The overall effect of the new market’s amalgamated approach to satellite design is that designers are now asking themselves how radiation-hardened their system components need to be. The International Space Station provides an excellent example of this new thought process in action. Parts on the Space Station have vastly different radiation requirements based on how critical they are to the entire system. Non-critical systems, such as experiments, are allowed SEL tolerances as low as 14 MeV. On the other hand, mission-critical systems, such as life support, have much higher SEL tolerances – as low as 37 and as high as 80, depending on the part.

Some parts even fall outside of these very general guidelines. Many Space Station systems are connected via Ethernet, much the same way that computers in an office are connected to one another. So far, Space Station engineers have not found an Ethernet device that meets the wide range of SEL and SEU tolerances. And the community is so divided over how to attack this problem that each Space Station contractor has been forced to design and implement its own Ethernet solution.

- Entangled photon sources for quantum communications - December 14, 2022

- Using optical transceiver technology within space vehicles - November 8, 2022

- Issue 224 of ESCC QUALIFIED PART LIST (QPL) - March 21, 2022

0 comments on Rad-hard parts available in the market