Assessment of automotive EEE Components Suitability for Space applications

- Posted by Luis de Pablo Martinez

- On November 27, 2019

- 0

Agenda

- INTRODUCTION

- BACKGROUND

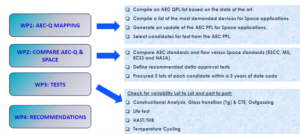

- ASSESSMENT TASKS DESCRIPTION

- TASK#1 THE AUTOMOTIVE AEC-Q MAPPING. AEC-QPL

- TASK#1 SELECT 3 AEC-Q CANDIDATES FOR TESTING

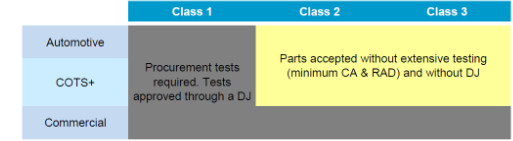

- TASK#2 COMPARISON AEC-Q AND SPACE – General Policy

- TASK#2 COMPARISON AEC-Q AND SPACE – Test Method Comparison

- TASK#3 PLANNED TESTING – ACTIVE

- TASK#3 PLANNED TESTING – CHIP CAPACITORS

- TASK#4 CONCLUSIONS & RECOMMENDATIONS : TO BE BUILT

INTRODUCTION

- Thales Alenia Space in Spain and Tyndall National Institute Ireland get a Contract with ESA No. 4000126343/19/NL/hh for the Assessment of Automotive EEE Components Suitability For Space Applications.

- Goal is to get info by analysis, market survey and testing refine recommendations for use of AEC devices in Space application according to mission criticality

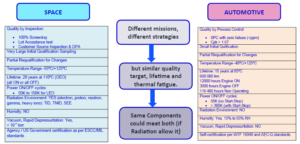

BACKGROUND

ASSESSMENT TASKS DESCRIPTION

TASK#1 THE AUTOMOTIVE AEC-Q MAPPING. AEC-QPL

- Mapping Task: AEC Description. History. Standard. ISO16949 & IAT16949. The PPAP

- Compilation of an Almost exhaustive AEC-Q QPL with components published at web as being Qualified AEC-Q100, or AEC-Q101 or AEC-Q200:

-

- 212288 items listed from the following 72 type families. 37K for AEC-Q100 +36K for AEC-Q101 + 176K for AEC-Q200. Total number estimated to be at 2019/09 around 600 000

-

- Data source: Big manufacturers and Distributors

-

- 117 manufacturers: with info about published certifications IATF16949 / PPAP available

-

- No yet devices qualified by neither AEC-Q102 (Optoelectronics) nor AEC-Q103 (MEM Sensors) nor AEC-Q104 (MCM) reported by manufacturers or distributors.

-

- Some families as Crystals, Oscillators and MEM’s could be listed under AEC-Q100 or AEC-Q200. Even same device offered either AEC-Q100 or AEC-Q200

-

- Most Optoelectronics are listed under AEC-Q101

-

- Most MCM are listed under AEC-Q100

-

- Most Sensors (pressure, temperature, accelerometers, gyroscopes, magnetic, proximity, hall effect..) are under AEC-Q100, other under AEC-Q200

-

- More than 70% of the microcircuits meet the Military Temperature Range (grade-0 plus grade-1). Similar for discrete and passive.

TASK#1 THE AUTOMOTIVE AEC-Q MAPPING. AEC-QPL (Cont’d)

- Some passive rated at very high temperature (resistors, capacitors, current ssnor uop to 2001C to 275ºC)

- Packages: some dice. 78% in plastic package. But 20% are encapsulated in ceramic packages like LCC, or mounted in ceramic support (ceramic chip RCL, themristors, filters, diodes). Less than 1% is found in metal packages.

- Majority are non hermetic non cavity. Some hermetic by technology (Crystal, oscillators and MEM, SAW Filters). Some new RF/MW devices work better inside air cavity package, these “almost” hermetic adhesive sealed ceramic lid.

- Critical packages (BGA, QFN, DFN, CSP), recognized by the automotive community as assembly critical because more sensitive to thermal fatigue with power on/off thermal cycling represents around 14% of AEC-Q100 microcircuits. DFN/QFN very popular in RF/MW, BGA/LGA almost “omnipresent” for high count FPGA/DSP/uControllers.

- SMD versus Through Hole. SMD accounts for 97%, while 3% for DIP axial, etc…

- Standard Chip Sizes: 0402, 0603, 0805, 1206, 1210, extended from capacitor and resistors to inductors, thermistors, EMI filters, diodes (DFN-2). Same trend seems to be extended to transistors (DFN-3) and MEM oscillators (DFN-4).

- Most (97%) but not all are published as RoHs compliant. But some with exception for high temperature solders

- Most manufacturers are from US & Europe & Japan, but with manufacturing plants certified for automotive as per IATF16949 in Far East: mainly China and Taiwan.

TASK#1 THE AUTOMOTIVE AEC-Q MAPPING. AEC-QPL (Cont’d)

- Most manufacturers are from US & Europe & Japan, but with manufacturing plants certified for automotive as per IATF16949 in Far East: mainly China and Taiwan.

- Some European are very active as EPCOS/TDK, Fastron, Infineon Technologies, Jauch Quartz, RF360 (Qualcomm/TDK), ROHM Semiconductor, TDK-Micronas, Vishay / BC Components, Vishay / Beyschlag, Wurth Electronics (in Germany). ATMEL Microchip Technology; ST Microelectronics (in France). Melexis Technologies NV (in Belgium). IQD Frequency Products; Knowles / Syfer; TT Electronics; Welwyn Components / TT Electronics (in UK). Nexperia & NXP in Netherlands. Nordic Semiconductor in Norway. Micro Crystal in Switzerland.

- Top-10 IC suppliers accumulate 85% of automotive, and Top-19 around 95% for more than 70 suppliers.

- Some technologies almost not seen in Space: Power GaN; Power SiC; MEM (oscillators); Sensors: pressure, temperature, accelerometers, gyroscopes, ARM magnetic, proximity, hall effect, ambient light, angle and linear position, measuring Infrared Emitters; High End Memories (DDR, Flash, FRAM, MRAM), microprocessors and FPGAs; Very Low Voltage Logic Families (17SZ; 27WZ; 37WZ; 74ABT; 74AUP; 74AVC; 74AXC; LSF; TCB; TWL; TXB; TXS, etc..); Triacs, Thyristor, SCRs; Aluminium Capacitors; Safety capacitors (line to ground capacitors); Ceramic Disc capacitors; BAW Filters; Varistors; Resettable fuses; Battery chargers, battery management; USB protection, Lighting Protection Diodes; Transponder coils, etc.

- Some technologies forbidden for Space: Aluminium Electrolytic Capacitors; Non swept Quartz and Quartz-based Oscillators; fuses: Resettable PPTC & wire link; SCR / Thyristor; Varistors, etc.

TASK#1 SELECT 3 AEC-Q CANDIDATES FOR TESTING

- All the three European ones per AEC-Q standard and from big manufacturers

- AEC-Q100: Op Amp, Output rail-to-rail, very low-noise, TSSOP-14 package

- AEC-Q101: Diode, Silicon, switching, high speed

- AEC-Q200: Capacitors, fixed, chip, ceramic dielectric type II, flexible termination based on type 1210

TASK#2 COMPARISON AEC-Q AND SPACE – General Policy

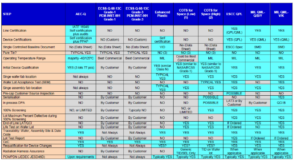

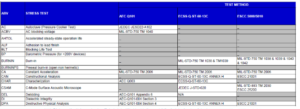

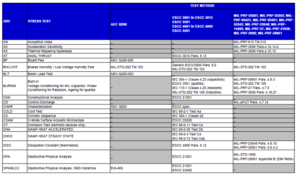

TASK#2 COMPARISON AEC-Q AND SPACE – Test Method Comparison

- Test methods comparison between AEC, ESCC, MIL, ECSS-Q-ST-60-14 and NASA GSFC PEM-INST-001 as applicable for microcircuits (AEC-Q100), discrete semiconductors (AEC-Q101), and passive devices (AEC-Q200)

- Also comparison for Diodes & LEDs (AEC-Q102), MEM sensors (AEC-Q103) and MCM (AEC-Q104) are included.

- Detailed comparison for Qualification / LAT of AEC standard and ECSS-Q-ST-60-14, NASA GSFC PEMS-INT-001, ESCC / MIL as applicable

- Examples:

TASK#2 COMPARISON AEC-Q AND SPACE – Test Method Comparison (Cont’d)

TASK#3 PLANNED TESTING – ACTIVE

- 3 Lots being procured for each device spreading a manufacturing period of 3/4 years

- 5 pieces Constructional Analysis as per ECSS-Q-ST-60-13C

- 10 pieces THB (1000h 85C/85%RH with preconditioning) with parts soldered onto board

- 10 pieces High temperature Operating Life Test HTOL (1000hours 125ºC) with parts soldered onto board

- 10 pieces Thermal Cycling TC (with preconditioning and 3 pieces C-SAM before and after test) 500 cycles -55ºC to +125ºC as per MIL-STD-883 TM1010 / MIL-STD-750 TM 1051 with parts soldered onto board

- Final C-SAM to be done without desoldering from board

- Glass Transition Temperature / CTE by DSC or TME (complete component with lead frame)

- Outgassing (only cut molding)

TASK#3 PLANNED TESTING – CHIP CAPACITORS

- NASA Alerted in 2016 about variability from lot to lot on Flexible/Non Flexible construction, and Some maverick lots failing Life test.

- NASA Alerted in 2018 of the fact that most sensitivity to cracking of MLCC capacitors is not detected on component alone but on component soldered onto board. We recommended to check variability from lot to lot in DPA & Life Test using capacitor soldered onto board, using polyimide boards, IR SnPb soldering.

- Testing proposed is

-

- HTOL 10PCS 1000hour 125ºC Maximum voltage rating. No moisture inside the oven.

-

- Biased Humidity Test (Low Voltage Humidity Test). As per ESCC3009 1000h 85ºC 95%RH 1.5V

-

- For Rapid Change of Temperature : see comparative

AEC

- 1000 cycles -55ºC/+125ºC

- 1min transition time

- 30minutes dwell time

ESCC

- 10 cycles 55ºC/+125ºC

- 1min transition time

- 30minutes dwell time

- on soldered components

ECSS-Q-70-38C1

- 500 cycles 55ºC/+100ºC

- 5 to 12ºC/min (or lower)

- 15minutes dwell time

TASK#4 CONCLUSIONS & RECOMMENDATIONS : TO BE BUILT

Some Expected Results:

- No variability part to part and lot to lot (we hope!). No maverick lots/parts

- No difference in construction, materials

- Consistency for Tg/CTE /Outgassing results between lots

- No whisker longer than 15 to 25um on pure tin exposed areas after soldering onto board and 500 thermal cycles, Life & THB (JESD-201 class 2 requirements for the testing proposed)

Some expected recommendations:

- Constructional Analysis and Tg/CTE recommended to be done on each new lot to substantiate similarity in ECSS-Q-ST-60-38C1 mounting qualification (presently not allowed for COTS)

- Only Constructional Analysis needed for AEC parts for grade-2 & 3 mission.

- Full qualification needed only on 1st lot of AEC parts for grade-2 & 3 mission.

- No SnPb retinning needed based on JESD-201 class 2 and further preventive measures (coating, barriers, etc..)

Latest posts by Luis de Pablo Martinez (see all)

- TAS’ Experience with AEC Devices in Launcher Applications - December 3, 2019

- Assessment of automotive EEE Components Suitability for Space applications - November 27, 2019

0 comments on Assessment of automotive EEE Components Suitability for Space applications