COTS in Space

- Posted by Dan Friedlander

- On December 3, 2019

- 0

COTS Population

-

-

- The term “COTS” (Commercial Off-The-Shelf) refers to a huge EEE Components population, including all the commercial grade ones (industrial, commercial, consumers, automotive etc.).

- Referring to COTS, there should be no place for hasty generalization.

- Quote: “All generalizations are false, including this one.” – Mark Twain.

-

COTS Characteristics

-

-

- High Volume Production ensure efficiency of using statistical tools.

- Statistical Process Control (SPC) used in production line to prevent defects, translated into reliability.

- Better lot homogeneity, higher the value of sampling.

- No screening.

-

Global Developments

-

-

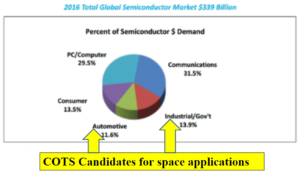

- Decrease of Military/Space Components market today to 0.1% of the world market (in dollars) from 60% in the 1960.

- Components Availability are dictated by manufacturers’ decisions based on market demand.

- Huge Technological Progress in solving reliability issues encountered in the last four decades.

-

Global Developments Impact

GLOBAL DEVELOPMENTS

lead to Cultural Change from

Use of Space/Military EEE Components

to

Use of Commercial EEE Components

1994 Perry memo

-

-

- 1994 Perry’s memo legalizes the use of COTS in military applications.

- Space applications are exempted.

- Main drivers:

-

-

-

-

- Defense Budget shrinking.

- Military components shrinking availability.

- Need for advanced technologies.

-

-

-

-

- The memo states “The use of military specifications and standards is authorized as a last resort, with an appropriate waiver”.

- The reversed components selection priority order is clear.

- It is big step to recognize officially the global developments, in an atmosphere of strong resistance to change.

-

REMEMBER

-

-

- The transition to COTS has a big potential for cost savings in military applications.

- The cost savings are realized with COTS used as is.

- For space applications the COTS are not used as is.

- The transition to COTS has a big potential for cost savings in military applications.

-

Methodology Change

-

-

- The global developments lead to the need for a new methodology adapted to deal with COTS for military projects. The space applications were exempted from 1994 Perry’s directive.

- The EEE Components Selection Policy has been changed to COTS becoming first priority selection

- A 20 years retrospective summary of properly selected COTS use across various military (air, ground, sea) and space applications (LEO) proves that COTS are OK.

-

MIL-PRF/QML Methodology

-

-

- Liberalized methodology following 1994 Perry’s directive.

- Transition from MIL-SPEC cookbook “how to” specifications to performance specifications.

- Transition from component level QPL to product line level QML.

- Components manufacturers get the authority to eliminate justified non-value added screening/ testing steps.

-

COTS

-

-

- Following 1994 Perry’s directive Commercial Off-The-Shelf (COTS) has been legalized for use in military applications.

- COTS dominate the global market (99.7% in $).

- Market Size = Incentive to invest in technological developments.

- High Volume Production = Valued Statistical Tools in Process Control = Reliability.

- Most failures are due to component manufacturing defects.

-

COTS in Space Official Policy

-

-

- The main leading COTS in space policy documents:

- NASA PEM-INST-001 (June 2003) – Instructions for Plastic Encapsulated Microcircuit (PEM) Selection, Screening, and Qualification.

- ESA ECSS-Q-ST-60-13C (21 October 2013) – Space product assurance commercial electrical, electronic and electromechanical (EEE) components.

- NASA PEM-INST-001 (June 2003) – Instructions for Plastic Encapsulated Microcircuit (PEM) Selection, Screening, and Qualification.

- The main leading COTS in space policy documents:

-

-

-

- The traditional methodology of dealing with space/military grade EEE components has been extended (with some tailoring) to commercial EEE components.

- The policy imposes on the user a “last resort” a COTS selection path vs. preferred Space/MIL components.

- The selection of COTS is penalized.

-

COTS in Space Debunking Myths

- Myth 1:

Incorrect interpretation of the term “space qualified”.

-

-

- The environmental requirements to be met are various, depending on many parameters like orbit, mission criticality, mission duration, etc.

- The term “space qualified” shall be fully understood in context of the specific component specification and in context of the intended application.

- The term “space qualified” refers often to the component quality level, unless RHA is specified.

-

- Myth 2:

The main drive to use COTS in space is cost savings.-

- Compare apple to apple, namely component ownership cost.

- Component Ownership Cost = Component Pre-procurement Cost (NRE) + Component Procurement Cost (RE) + component Post Procurement Cost (NRE).

- The main drive: component availability to meet performance and/or Size, Weight, Power (SWaP).

-

- Myth 3:

Incorrect interpretation of the term “space heritage”.-

- Compare apple to apple, namely mission to mission.

- Space missions are various:

- Scope: scientific, in orbit demonstration, operational …

- Orbits: LEO, GEO.

- Mission duration: <1 year to 15 years.

-

- Myth 4:

Use of terms “quality” and “reliability” interchangeably.

-

-

- Quality and reliability are two terms referring to two entirely different aspects of the behavior of a component over its lifetime.

- Quality measures how well the facility produces components that meet the specifications at the start of use.

- Reliability is the probability of a component meeting the relevant specification over the lifetime.

-

- Myth 5:

COTS reliability cannot be ensured, unless they are 100 percent tested and screened.

-

-

- Reliability cannot be tested into the component.

- The qualification and screening are not considered as a substitute for manufacturing control, but rather as risk-mitigation measures.

- Process (design followed by manufacturing) builds reliability into the component.

- Statistical Process Control (SPC) addresses the reliability issue.

-

- Myth 6:

Meeting absolute quantitative limit of reliability is required in technical specifications in order to achieve the needed mission reliability.

-

-

- MIL-HDBK-217F explicitly states: “A reliability prediction should never be assumed to represent the expected field reliability”.

- As MIL-HDBK-217F admits, “those who view the prediction only as a number which must exceed a specified value can usually find the way to achieve their goal without any impact on the system”.

-

- Myth 7:

Plastic encapsulated semiconductors (PEM) cannot be used for space applications.

-

-

- The problems encountered in early stages (from the 1960s) with non-hermetic plastic encapsulated semiconductors caused the military and space components policymakers to taboo (avoid or ban) their use in military and space applications.

- If properly stored, there is no problem using non-hermetic components in space.

- In space there is no moisture.

-

- Myth 8:

COTS manufacturing is not controlled sufficiently.

-

-

- The history does not show that a central control has been efficient for military components.

- The military-level qualified components (widely used in space) and COTS have the same lack of wafer traceability problem.

- The space industry turns a blind eye on the lack of wafer traceability for traditionally accepted military level components, but penalizes COTS in space because of the same traceability issue!

-

- Myth 9:

Success in space missions can be achieved only by means of a conservative approach.

-

-

- Space missions are inherently risky.

- No approach, not even a conservative one, can avoid failures.

- The name of the game is risk management.

- Today, there is enough proof (see U.S. private space industry) that progressing with a more liberal approach is a valid way to success.

-

- Myth 10:

Redundancy is a magic solution to enable the use of softer radiation components.

-

-

- Redundancy, if found necessary, is a good practical solution for lowering the probability of system failures.

- The same type of components are expected to fail independently in the same design.

- This may be outweighed by other risk factors, such as human design error, generic failure modes, etc.

- True redundancy: implementation with different designs designed by different teams.

-

COTS in Space – The Future Input to Forecast

- Input Data for the Forecast:

-

-

- The traditional MIL methodology for space and military applications, based on heavy testing/screening of hermetically sealed electronic components, is deeply rooted in the ongoing environment of resistance to change.

- EEE COTS components, in spite of huge technological developments, were banned for decades to be used in military and space applications.

-

- The MIL traditional methodology rigidity and the commercial market dominance lead to a considerable technological lag of military/space EEE components behind commercial ones.

- The military/space EEE components market size led to components manufacturers business decisions to leave the military/space market, further affecting the availability.

- It has been proven that components manufacturers are independent in taking business decisions.

- Budgets are shrinking.

-

-

- After long debates the US DoD officially was compelled (by global developments) to recognize the legitimacy of usage of EEE COTS components in military applications.

- The decision to use of EEE COTS components in military applications has been proved as a successful one from every aspect.

-

- The above decision has led to replacing the MIL traditional methodology with the QML concept, a liberalized version of the traditional one, infused with elements of commercial practices.

- The space applications have been exempted (DoD is not responsible for space) from the above decision.

- Meanwhile, within local initiatives, EEE COTS components were successfully used in space applications.

- Extremely slow space policy makers decision taking led to a last resort EEE COTS components penalized methodology.

- The present space policy leads to preference of military/space grade, hermetically sealed EEE components in space applications.

-

The only thing certain about the availability security of the military/space EEE components is uncertainty.

-

COTS in Space – Forecast

-

-

- It is obvious that without electronics the space industry cannot survive. Consequently, the availability of the electronic components is a MUST.

- Presently, most of the space designs are based on military/space grade hermetically sealed electronic components, meeting the space agencies’ policies.

- The direct consequence is to commit those designs to insecure components availability.

- The availability of military/space grade EEE Components depends solely on business decisions By Components Manufacturers, based on a miniscule space demand (less than 0.3% in $).

- The business minded movement of the semiconductor industry to economy of scale cannot be stopped.

- Not profitable markets will disappear.

- Like for military, COTS in space is considered a viable disruptive alternative.

- The policy makers’ duty should be to lead proactively the industry into the future.

They have to adapt to the NewSpace philosophy, otherwise they may become irrelevant. - New thinking is urgently needed to accelerate new policy creation efforts.

- It is obvious that without electronics the space industry cannot survive. Consequently, the availability of the electronic components is a MUST.

-

COTS in Space Official Methodology To be changed

Albert Einstein wrote: “We cannot solve our problems with the same thinking we used when we created them”.

Latest posts by Dan Friedlander (see all)

- Talking On COTS For Space With Dan Friedlander. Episode 10: Pragmatic Policy Wanted - May 16, 2024

- Talking on COTS for space with Dan Friedlander. Episode 8: Policy making progress - January 16, 2024

- Talking on COTS for space with Dan Friedlander. Episode 7: RHA Component vs Product - November 20, 2023

0 comments on COTS in Space